A kind of tussah silk fibroin protein microsphere containing three-dimensional hole structure and preparation method thereof

A technology of tussah silk fibroin and pores, which is applied in the field of textile materials, can solve the problems of unfavorable fabric feel and air permeability and moisture permeability, and there are not many porous fibroin particles, so as to achieve good skin-friendly and air permeability and moisture permeability. The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

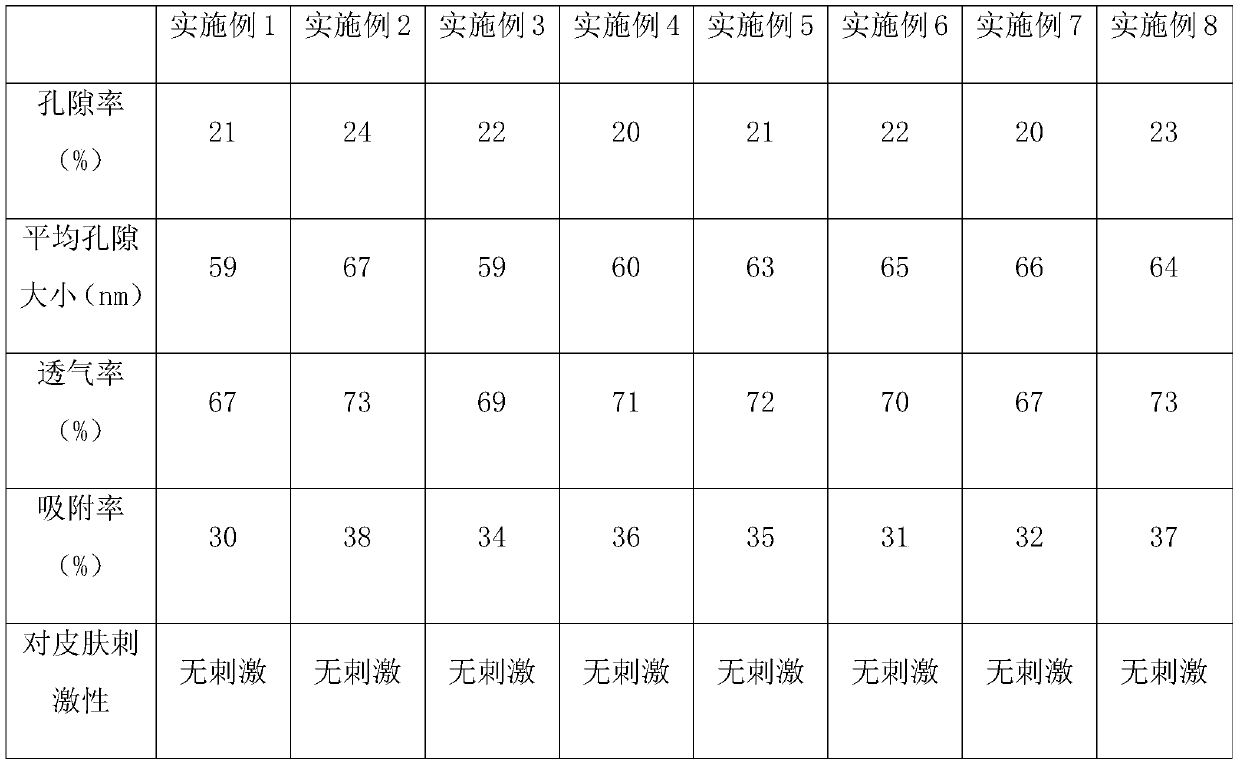

Examples

Embodiment 1

[0024] (1) use tussah silk as raw material, after degumming, be 1g:10ml with solid-liquid ratio, be placed in lithium bromide solvent and dissolve completely at 60 ℃, dialyze, separate, add the elastase solution that mass fraction is 0.5%, in Enzymolysis at 10° C. for 30 minutes, heat inactivation at 80° C., and concentration to obtain a tussah silk fibroin protein solution, wherein the tussah silk fibroin protein has a molecular weight of 15-30 kDa.

[0025] (2) Add 0.5 parts of azobisisobutyronitrile foaming agent and 1 part of glutaraldehyde and citric acid crosslinking agent to the aqueous solution containing 1 part of tussah silk fibroin protein in parts by mass, and let it stand at 20 ° C 2 minutes, stirred for 60 minutes, and centrifuged to form tussah silk fibroin particles.

[0026] (3) In parts by mass, add 1 part of tussah silk fibroin protein particles into an aqueous solution containing 6 parts of sodium chloride, heat and stir at a temperature of 95°C and a speed...

Embodiment 2

[0028] (1) use tussah silk as raw material, after degumming, be 1g: 10ml with solid-liquid ratio, be placed in lithium bromide solvent and dissolve completely at 60 ℃, dialyze, separate, add the elastase solution that mass fraction is 2%, in Enzymolysis at 15°C for 60 minutes, heat inactivation at 80°C, and concentration to obtain a tussah silk fibroin protein solution, wherein the tussah silk fibroin protein has a molecular weight of 15-30kDa.

[0029] (2) Add 0.8 parts of azobisisobutyronitrile foaming agent and 2 parts of glutaraldehyde and citric acid crosslinking agent to the aqueous solution containing 1 part of tussah silk fibroin protein in parts by mass, and let it stand at 25 ° C 5 minutes, stirred for 90 minutes, and centrifuged to form tussah silk fibroin particles.

[0030] (3) In parts by mass, add 1 part of tussah silk fibroin protein particles into an aqueous solution containing 10 parts of sodium chloride, heat and stir at a temperature of 98° C. and a speed o...

Embodiment 3

[0032] (1) use tussah silk as raw material, after degumming, be 1g:10ml with solid-liquid ratio, be placed in lithium bromide solvent and dissolve completely at 60 ℃, dialyze, separate, add the elastase solution that mass fraction is 1%, in Enzymolysis at 12° C. for 45 minutes, heat inactivation at 80° C., and concentration to obtain tussah silk fibroin protein solution, wherein the tussah silk fibroin protein has a molecular weight of 15-30 kDa.

[0033] (2) Add 0.6 parts of azobisisobutyronitrile foaming agent and 1.5 parts of glutaraldehyde and citric acid crosslinking agent to the aqueous solution containing 1 part of tussah silk fibroin protein in parts by mass, and let it stand at 23 ° C 3 minutes, stirred for 70 minutes, and centrifuged to form tussah silk fibroin particles.

[0034] (3) In parts by mass, add 1 part of tussah silk fibroin protein particles into an aqueous solution containing 8 parts of sodium chloride, heat and stir at a temperature of 97° C. and a spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com