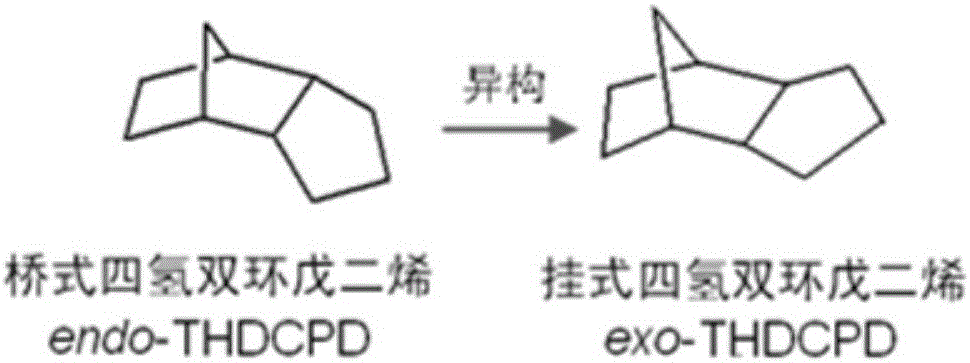

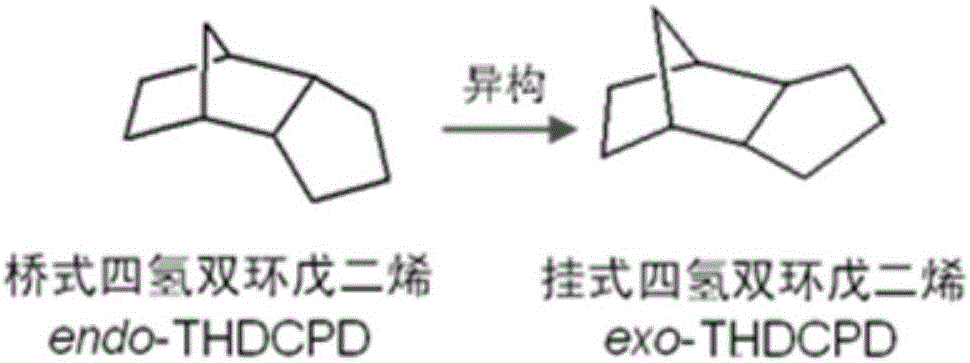

Preparation method of endo-tetrahydrodicyclotadiene isomerization catalyst

A technology of tetrahydrodicyclopentadiene and catalyst, which is applied in isomerization to hydrocarbon production, carbon compound catalyst, physical/chemical process catalyst, etc., can solve the problems of low conversion rate, water sensitivity, shortening the service life of catalyst, etc. The effect of improving activity stability, good activity and selectivity, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

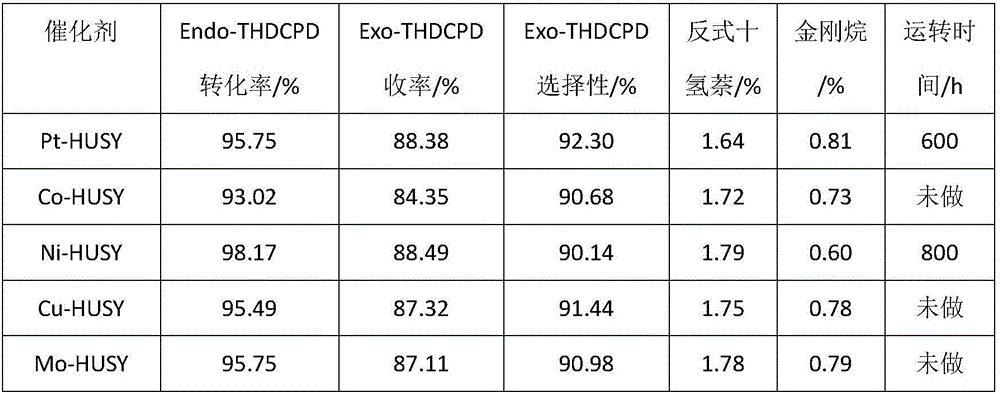

Examples

Embodiment 1

[0027] A preparation method of a bridged tetrahydrodicyclopentadiene isomerization catalyst, comprising the steps of:

[0028] A preparation method of a bridged tetrahydrodicyclopentadiene isomerization catalyst, comprising the steps of:

[0029] (1) Forming of ultra-stable Y-type molecular sieve: In terms of mass percentage, the ultra-stable Y-type molecular sieve is 40%-90%, and the pore volume is 0.2-0.6cm 3 / g alumina 5%-40%, pore volume 0.8-1.2cm 3 5%-20% of aluminum oxide per gram and 2% of safflower powder are fully mixed evenly, and then add nitric acid solution with a mass concentration of 10%. Glacial acetic acid solution with a mass concentration of 5%, the addition ratio of the glacial acetic acid solution is 15-25% of the mass of the raw material powder, after fully mixing evenly, extrude into cylindrical strips with a diameter of 1.6mm, dry naturally, and dry at 120°C for 3 -4h, roast at 400-600°C for 4h, take it out and make 2-3mm long particles; or in terms o...

Embodiment 2

[0039] A preparation method of a bridged tetrahydrodicyclopentadiene isomerization catalyst, the steps are the same as in Example 1, preferably, in the step (1) of Example 1, the ultra-stable Y-type molecular sieve is 60%-85%, the pore volume is 0.3-0.5cm 3 / g alumina 10%-25%, pore volume 0.85-1.0cm 3 / g alumina 5%-15%.

[0040] Preferably, in embodiment 1, according to the platinum loading in step (2), 0.3%-0.8% of the quality of the ultra-stable Y-type molecular sieve shaped particle carrier prepared in step (1) is used to prepare chloroplatinic acid-hydrochloric acid solution, etc. The ultra-stable Y-type molecular sieve shaped particle carrier prepared in the volume impregnation step (1) is dried at room temperature, dried at 120°C for 3-4h, and calcined at 400-500°C for 4h to obtain the platinum-loaded catalyst Pt-HUSY.

[0041] Preferably, in Example 1, in step (2), iron, cobalt, nickel, copper, Molybdenum nitrate solution or ammonium molybdate solution, the ultra-sta...

Embodiment 3

[0045] Take 140g of ultra-stable Y-type molecular sieve raw powder with a sodium content of 0.3% and a silicon-aluminum ratio of 8.2, 40g of small-pore alumina raw powder, 20g of macroporous alumina raw powder, and 4g of scallop powder, mix well, and add 10% by mass % nitric acid solution 40mL, after fully kneading, add 40mL of glacial acetic acid solution with a mass percentage content of 5% and deionized water 15mL, continue to fully knead, and extrude into a cylindrical strip with a diameter of 1.6mm. After natural drying, dry at 120°C for 3 hours, and bake at 550°C for 4 hours. Take it out and make 2-3mm long particles, which are recorded as carrier 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com