Preparation method of pseudo-boehmite

A pseudo-boehmite and bottom water technology, applied in the preparation of alkali metal aluminate/alumina/hydroxide, reagents, educts, etc., can solve the problem of amorphous pseudo-boehmite and sol aggregation into gel Glue, uneven particle size distribution and other problems, to achieve the effect of complete crystal grains, improved purity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

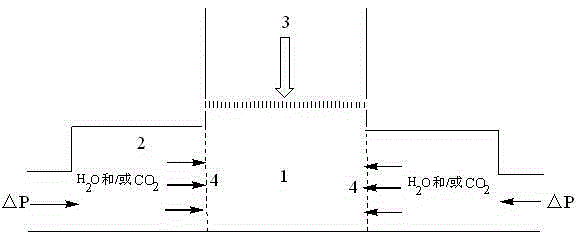

Embodiment 1

[0042] 1 L of bottom water and 8.7 g of ethylene glycol were added to the bottom of Reactor 1, and the reaction temperature was adjusted to 30°C. Regulate the feed rate of feed pipe on the reactor, the NaAlO that concentration is 10g / 100ml 2 The flow rate of the solution is 20ml / min and CO is injected at a flow rate of 2.5L / min through the semi-permeable membrane from the bottom. 2 After forming a gel for 20 minutes, after the aluminum hydroxide sol reaches 7.6g / 100ml, apply a specific pressure in the pressure zones on both sides, keep the pressure difference △P between 1.0-2.0MPa, and maintain the sol concentration at 5-15g / 100ml In between, continue to react for 1.0h. After the reaction, start ultrasonic oscillation, adjust the pH value of the reactor to 5.0 and increase the reaction temperature to 80°C in the high temperature section at a rate of 10°C / min, and perform aging for 1.0h. The aging pH value is 5.0 . After aging, pressurize the top of the reactor to pass water ...

Embodiment 2

[0045] Add 2L of bottom water and 10g of glycerol to the bottom of reactor 1, and adjust the reaction temperature to 40°C. Regulate the feeding speed of feed pipe on the reactor, the NaAlO that concentration is 15g / 100ml 2 The flow rate of the solution is 25ml / min and CO is injected at a flow rate of 3.5L / min through the semi-permeable membrane from the bottom. 2 After forming a gel for 30 minutes, after the aluminum hydroxide sol reaches 10g / 100ml, apply a specific pressure in the pressure zone on both sides, keep the pressure difference △P between 2.0-4.0MPa, and maintain the sol concentration between 5-15g / 100ml During the reaction, continue to react for 0.5h. After the reaction, start ultrasonic oscillation, adjust the pH value of the reactor to 5.5 and increase the reaction temperature to 90°C in the high temperature section at a rate of 20°C / min, and perform aging for 1.5h, and the aging pH value is 6.0. After aging, pressurize the top of the reactor to pass water throu...

Embodiment 3

[0048] 1.5L of bottom water and 8.7g of ethylene glycol were added to the bottom of reactor 1, and the reaction temperature was adjusted to 25°C. Regulate the feed rate on the reactor, and the NH concentration of 10g / 100ml 4 OH solution ml / min flow and inject CO at 4.5L / min flow through the semi-permeable membrane from the bottom 2 ,, After 20 minutes of gelling, after the aluminum hydroxide sol reaches 7.4g / 100ml, apply a specific pressure in the pressure zone on both sides, keep the pressure difference △P between 1.5-2.0MPa, and maintain the sol concentration at 5-15g Between / 100ml, continue to react for 1.0h. After the reaction is over, start the stirring paddle, adjust the rotation speed to 1500r / min, adjust the pH value of the reactor to 6.0 and raise the reaction temperature to 75°C in the high temperature section at a rate of 15°C / min. Aging for 2.0h, the aging pH value is 5.0. After aging, pressurize the top of the reactor to pass water through the semi-permeable me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com