Production method of cobalt sulfate monohydrate

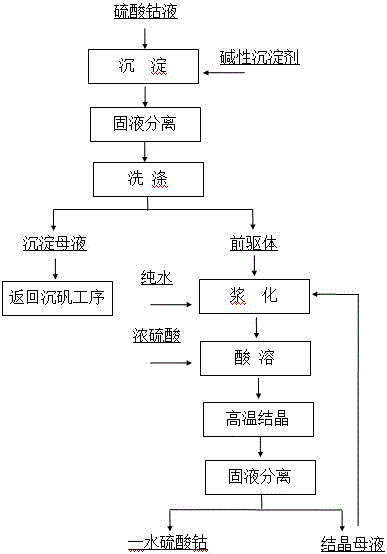

A production method and technology of cobalt sulfate, applied in directions such as cobalt sulfate, can solve problems such as high cost and complicated process flow, and achieve the effects of reducing content, avoiding accumulation, and avoiding high-temperature removal of crystal water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] After sulfuric acid leaching, extracting copper, precipitation and iron removal, P204 extraction and removal of impurities, and P507 extraction and back extraction, pure Co is obtained. 2+ 120g / L cobalt sulfate solution. Add Na to pure cobalt sulfate solution 2 CO 3 Carry out precipitation, the precipitated slurry is separated and washed by the filter press for solid-liquid separation, and the mother liquor and washing water are returned to the alum precipitation process of cobalt wet smelting. CoCO 3 The precipitate is transferred to the dissolving tank, and the pure water and mother liquor are stirred and slurryed uniformly, and then 98% concentrated sulfuric acid is quickly added for acid dissolution. The heat of reaction and dilution heats the acid solution slurry to 106 ºC, and the pH value of the solution reaches 4.5. Stop adding concentrated sulfuric acid. Transfer the acid solution into the autoclave and heat it to a temperature of 200 ºC, keep the slurry tempera...

Embodiment 2

[0021] After sulfuric acid leaching of laterite nickel ore, iron removal by precipitation, P204 extraction and removal of impurities, and P507 extraction and back extraction, pure Co is obtained 2+ 120g / L cobalt sulfate solution. NaOH is added to the pure cobalt sulfate solution for precipitation, the precipitated slurry is separated and washed by the filter press for solid-liquid separation and washing, the precipitation mother liquor and washing water are returned to the alum precipitation process of cobalt wet smelting, Co(OH) 2 The precipitate is transferred to the dissolving tank, and the pure water and mother liquor are stirred and slurryed evenly, and then 98% concentrated sulfuric acid is quickly added for acid dissolution. The heat of reaction and dilution heats the acid solution slurry to 70 ºC, and the pH value of the acid solution reaches 1.5. Stop adding concentrated sulfuric acid. The acid solution is transferred to an autoclave and heated to a temperature of 120 º...

Embodiment 3

[0023] After the cobalt-containing sulfide ore is leached by oxygen pressure, alumite is removed for iron removal, P204 is extracted for impurity removal, and P507 is extracted for back extraction, pure Co is obtained. 2+ 120g / L cobalt sulfate solution. Add NH to pure cobalt sulfate solution 4 HCO 3 Carry out precipitation, the precipitated slurry is separated and washed by the filter press for solid-liquid separation, and the mother liquor and washing water are returned to the alum precipitation process of cobalt wet smelting. CoCO 3 The precipitate is transferred to the dissolving tank, and the pure water and mother liquor are stirred and slurryed uniformly, and then 98% concentrated sulfuric acid is quickly added for acid dissolution. The heat of reaction and dilution heats the acid solution slurry to 88 ºC, and the pH value of the acid solution reaches 3.0. Stop adding concentrated sulfuric acid. Transfer the acid solution into the autoclave and heat it to a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com