Efficient sludge treatment agent and preparation method thereof

A high-efficiency technology for sludge treatment, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low sludge treatment efficiency, difficult sludge dewatering rate, large sludge volume, etc., to achieve easy industrial application, The effect of low production cost and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

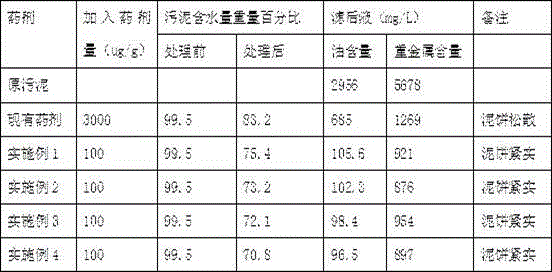

Examples

Embodiment 1

[0015] A high-efficiency sludge treatment agent, which is composed of the following raw materials in parts by weight: 26 parts of polyacrylamide, 3 parts of surfactant, 0.5 parts of nano-zinc oxide, 3 parts of glycerin, 11 parts of modified bentonite powder and modified rush 20 parts of powder, the modified rush powder is obtained by mixing rush powder with sodium acetate and potassium dihydrogen phosphate in a weight ratio of 100:1:2, stirring evenly and drying.

[0016] The preparation method of described efficient sludge treatment agent, concrete steps are as follows:

[0017] Step 1, dissolving glycerol and polyacrylamide in deionized water to obtain the first mixed solution, heating the first mixed solution to 35 degrees Celsius and adding a surfactant, stirring in a mixer at a speed of 150 rpm for 15 minutes to obtain the first mixed solution Two mixed solutions;

[0018] Step 2: Add modified bentonite powder and modified rush powder to the second mixed solution, stir e...

Embodiment 2

[0020] A high-efficiency sludge treatment agent, which is composed of the following raw materials in parts by weight: 29 parts of polyacrylamide, 6 parts of surfactant, 0.9 parts of nano-zinc oxide, 7 parts of glycerol, 15 parts of modified bentonite powder and modified rush 24 parts of powder, modified bentonite powder is calcined bentonite in a calcination furnace at 450°C for 3 hours, cooled, crushed into 80-mesh particles, soaked in 10% hydrochloric acid solution for 2 hours, filtered out bentonite powder, washed with water , dried, and crushed into 200-mesh powder.

[0021] The preparation method of described efficient sludge treatment agent, concrete steps are as follows:

[0022] Step 1, dissolving glycerol and polyacrylamide in deionized water to obtain the first mixed solution, heating the first mixed solution to 40 degrees Celsius and adding a surfactant, stirring in a mixer at a speed of 200 rpm for 17 minutes to obtain the first mixed solution Two mixed solutions;...

Embodiment 3

[0025] A high-efficiency sludge treatment agent, which is composed of the following raw materials in parts by weight: 32 parts of polyacrylamide, 7 parts of surfactant, 1.2 parts of nano-zinc oxide, 10 parts of glycerol, 18 parts of modified bentonite powder and modified rush 31 parts of powder, the surfactant is a mixture of anionic surfactant and nonionic surfactant, and the nano-zinc oxide is one or more of protease, lipase or cellulase.

[0026] The preparation method of described efficient sludge treatment agent, concrete steps are as follows:

[0027] Step 1, dissolving glycerol and polyacrylamide in deionized water to obtain the first mixed solution, heating the first mixed solution to 43 degrees Celsius and adding a surfactant, stirring in a mixer at a speed of 210rpm for 20 minutes to obtain the first mixed solution Two mixed solutions;

[0028] Step 2: Add modified bentonite powder and modified rush powder to the second mixed solution, stir evenly and cool to 26 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com