Preparation method of chromium-free tanning agent

The technology of a chrome-free tanning agent and an acid binding agent is applied in the field of preparation of a chrome-free tanning agent, and can solve the problems of low free formaldehyde content, easy detanning, energy consumption, time-consuming and the like, and achieves a simple and easy operation process, Short tanning time and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

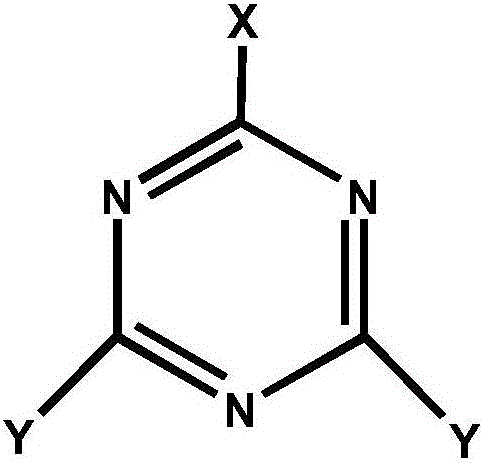

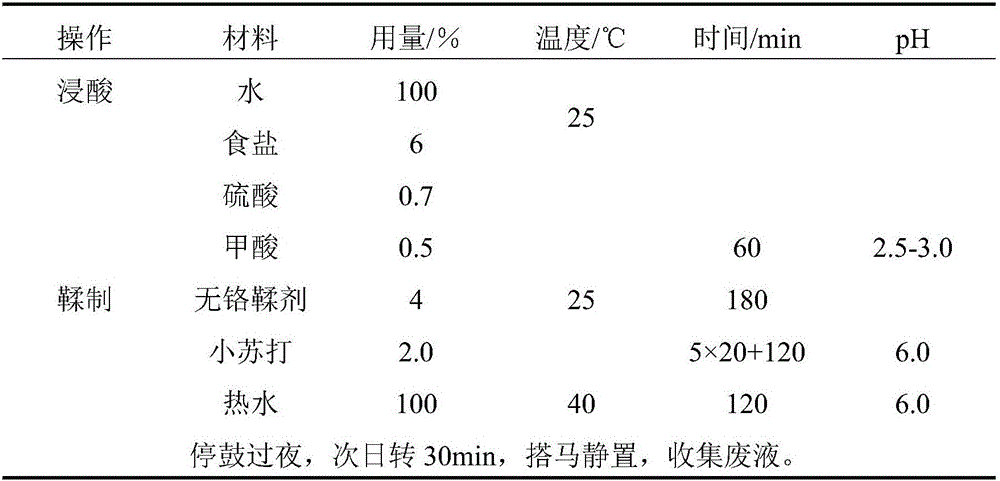

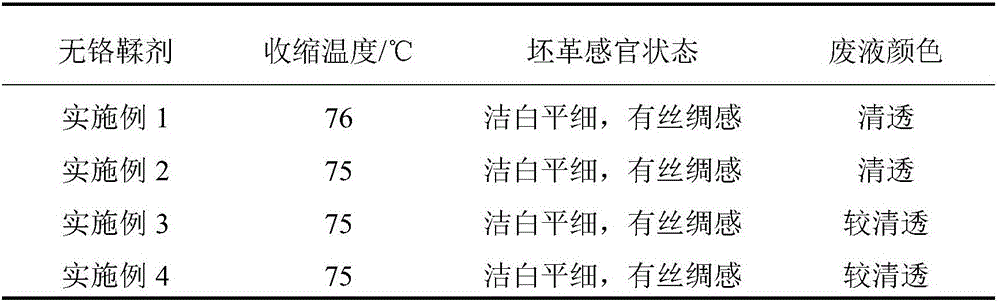

[0019] Embodiment 1, a kind of preparation method of chrome-free tanning agent comprises the following steps:

[0020] 1) Add 17.4g of p-hydroxybenzenesulfonic acid and 150g of deionized water into a four-neck flask, neutralize with 4g of sodium hydroxide, keep stirring until dissolved, put it in an ice bath, and add 18.5g of cyanuric chloride at one time , keeping the temperature at 0°C, continuously adjusting the pH of the system with a sodium carbonate solution with a mass concentration of 10%, until the pH of the system is stable at 5.0, and then continuing to react for 1.0 h to obtain a mixture A;

[0021] 2) Mixture A is warmed up to 40 DEG C, and 12.2 g of p-Hydroxybenzaldehyde dissolved in 20 g of acetone are added dropwise with stirring, and the pH of the system is constantly adjusted with a sodium carbonate solution with a mass concentration of 10%, so that the pH is stabilized at 6.5. Continue to react for 3.0 hours after the addition of materials; raise the tempera...

Embodiment 2

[0023] Embodiment 2, a kind of preparation method of chrome-free tanning agent comprises the following steps:

[0024] 1) Add 17.3g of p-aminobenzenesulfonic acid and 150g of deionized water into a four-neck flask, neutralize with 4g of sodium hydroxide, keep stirring until dissolved, put it in an ice bath, and add 18.5g of cyanuric chloride at one time , keeping the temperature at 5°C, continuously adjusting the pH of the system with a potassium carbonate solution with a mass concentration of 10%, until the pH of the system is stabilized at 6.0, and then continuing to react for 1.5 hours to obtain a mixture A;

[0025] 2) Mixture A is warmed up to 40 DEG C, and 12.2 g of p-Hydroxybenzaldehyde dissolved in 20 g of acetone is added dropwise with stirring, and the pH of the system is constantly adjusted with a potassium carbonate solution with a mass concentration of 10%, so that the pH is stabilized at 6.5. Continue to react for 3.0 hours after adding the materials; raise the t...

Embodiment 3

[0027] Embodiment 3, a kind of preparation method of chrome-free tanning agent comprises the following steps:

[0028] 1) Add 13.8g of p-hydroxybenzoic acid and 150g of deionized water into a four-necked flask, and neutralize with 4g of sodium hydroxide, keep stirring until dissolved, then place it in an ice bath, and add 18.5g of cyanuric chloride at one time, Keeping the temperature at 2°C, continuously adjust the pH of the system with a sodium carbonate solution with a mass concentration of 10%, until the pH of the system is stable at 6.0, and then continue the reaction for 2.0 hours to obtain a mixture A;

[0029] 2) Mixture A is warmed up to 45 DEG C, and 12.2g of p-Hydroxybenzaldehyde dissolved in 20g of acetone is added dropwise with stirring, and the pH of the system is constantly adjusted with a sodium carbonate solution of 10% in mass concentration to make the pH stable at 6.5. Continue to react for 3.0 hours after adding the materials; raise the temperature of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com