Process for preparing maize germ oil in proper processing manner

A technology of corn germ oil and corn germ, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of low protein recovery rate, many equipments, and large loss of oil flavor, etc., and solve the problem of corn recycling Serious color, wide application prospects, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

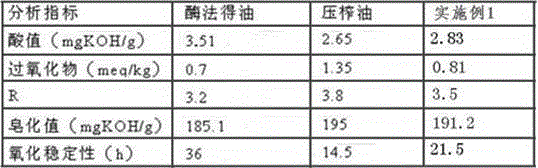

Embodiment 1

[0034] Take 10kg of corn germ (mass fraction) with a husk content of 15% and a moisture content of 7% (mass fraction), preheat the corn germ to 50°C, and directly put it into a low-temperature press for oil extraction to obtain wool Oil 9.3kg;

[0035] Heat the crude oil to 85°C, then add 45% citric acid (mass fraction) for acid reaction; cool the corn oil after acid reaction to below 45°C; then add 18.6kg of water, NaOH, and compound enzyme, the amount of NaOH added It is 2.33g; the compound enzyme uses 140mg of phospholipase A2, 112mg of phospholipase B, 93mg of phospholipase C, and 74mg of phospholipase D; then the oil-water system with enzyme is introduced into the reactor for 6 hours, and the degummed oil is obtained by centrifugation;

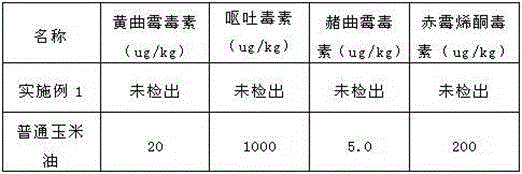

[0036] The mycotoxin removal process is carried out by the adsorption method. First, the degummed oil is preheated to 30°C, and then the composite adsorbent is added while stirring. The composite adsorbent includes 20g of magnesium silica...

Embodiment 2

[0041] Take 10kg of corn germ (mass fraction) with a husk content of 20% and a moisture content of 9% (mass fraction), preheat the corn germ to 50°C, and directly put it into a low-temperature press for oil extraction to obtain wool Oil 9.3kg;

[0042] Heat the crude oil to 85°C, then add 45% citric acid (mass fraction) for acid reaction; cool the corn oil after acid reaction to below 45°C; then add 18.6kg of water, NaOH, and compound enzyme, the amount of NaOH added It is 2.33g; the complex enzyme uses 140mg of phospholipase A2, 112mg of phospholipase B, 93mg of phospholipase C, and 74mg of phospholipase D; then the oil-water system with enzyme is introduced into the reactor for 6 hours, and the degummed oil is obtained by centrifugation;

[0043] The mycotoxin removal process is carried out by the adsorption method. First, the degummed oil is preheated to 30°C, and then the composite adsorbent is added while stirring. The composite adsorbent includes 10g of magnesium silicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com