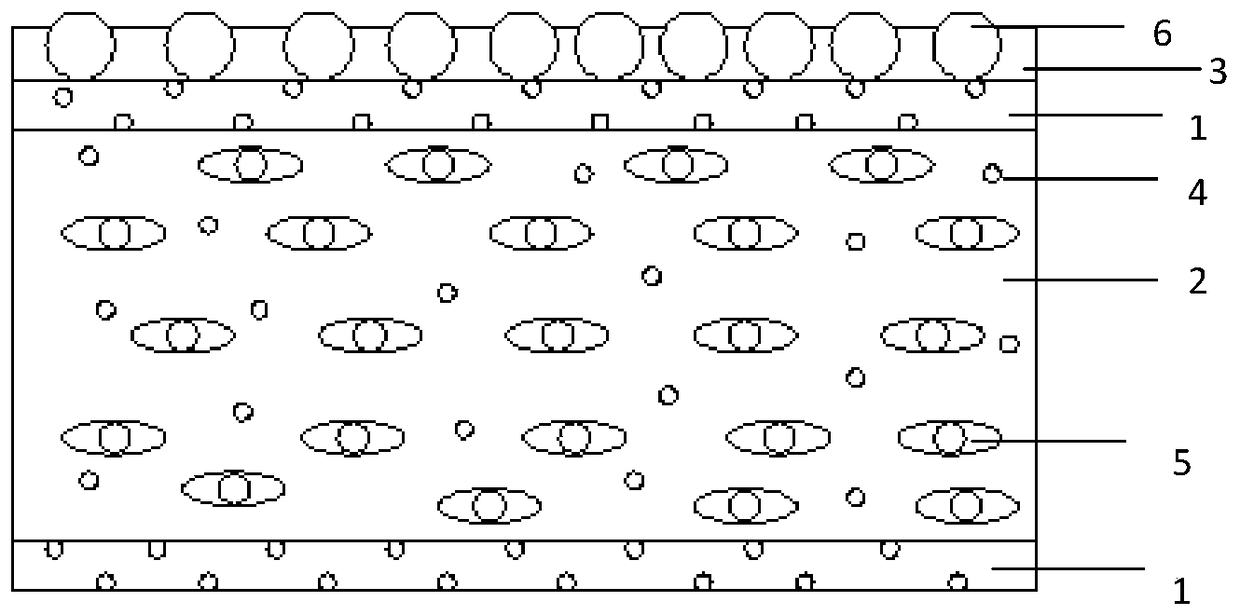

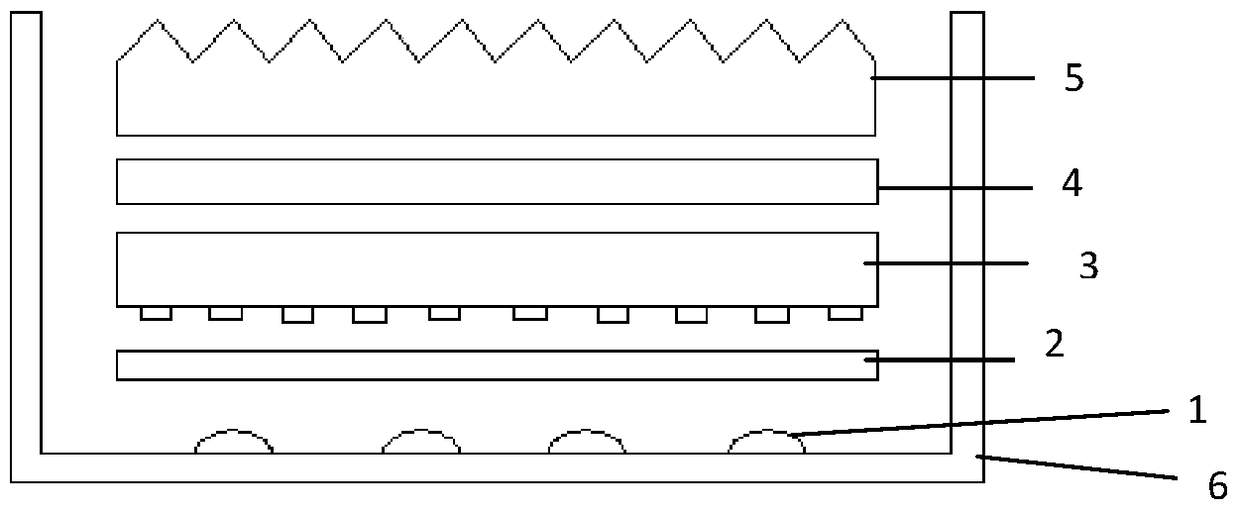

A kind of diffuse reflective film and its preparation method

A reflective film and diffusion technology, applied in the field of diffusion reflective film and its preparation, can solve the problems of easy generation of LED lights and shadows, affecting the picture quality of liquid crystal displays, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In the diffuse reflection film provided by the present invention, the ratio of layer A is 97.5% of PET slices, 2% of silicon dioxide particles, and 0.5% of nanoscale indium tin oxide. The ratio of layer B is 65% PET chips, 10% rutile titanium dioxide, 20% polymethylpentene, and 5% benzotriazole ultraviolet absorber. The diffusion glue coating is composed of the following components: 55% mixed solvent (butanone: ethyl acetate = 1:1), 35% acrylate adhesive, 7% aliphatic polyisocyanate, 3% particle size of 25- For 30 μm polybutylmethacrylate diffusion particles, the stated percentages are percentages by mass. The thickness of layer A accounts for 6% of the total thickness, the thickness of layer B accounts for 88% of the total thickness, and the thickness of the diffusion coating is 25 μm. The obtained reflective film substrate has a thickness of 300 μm, and the relevant properties are shown in Table 2.

Embodiment 2

[0067] In the diffuse reflection film provided by the invention, the ratio of layer A is 94% of PET chips, 4% of silicon dioxide particles, and 2% of ethoxylated aliphatic alkylamines. The ratio of layer B is 74% PET chips, 8% BaSO 4 , 15% cyclic olefin copolymer resin, 3% benzotriazole UV absorber. The diffusion glue coating is composed of the following components: 60% solvent (toluene: methyl ethyl ketone = 1: 1), 30% polyurethane adhesive, 5% aliphatic polyisocyanate, 5% polyformaldehyde with a particle size of 27-33 μm Diffusion particles of methyl acrylate, the percentage content is mass percentage content. The thickness of layer A accounts for 6% of the total thickness, the thickness of layer B accounts for 88% of the total thickness, and the thickness of the diffusion coating is 25 μm. The obtained reflective film substrate has a thickness of 300 μm, and the relevant properties are shown in Table 2.

Embodiment 3

[0069] In the diffuse reflection film provided by the invention, the ratio of layer A is 92% of PET slices, 6% of silicon dioxide particles, and 2% of ethoxylated aliphatic alkylamines. The proportion of layer B is 70% PET chips, 10% CaCO 3 , 15% polymethylpentene, 5% benzotriazole UV absorber. The diffusion glue coating is composed of the following components: 55% solvent (toluene:ethyl acetate=1:1), 35% epoxy resin adhesive, 7% aliphatic polyisocyanate, 3% particle size of 25-30 μm The polybutyl methacrylate diffusion particles, the percentage content is mass percentage content. The thickness of layer A accounts for 6% of the total thickness, the thickness of layer B accounts for 88% of the total thickness, and the thickness of the diffusion coating is 25 μm. The obtained reflective film substrate has a thickness of 300 μm, and the relevant properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com