Water purification and aeration method and equipment for closed recirculating aquaculture system

A water purification, closed cycle technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Pressure increase and other problems, to achieve the effect of increasing oxygen mass transfer efficiency, prolonging gas-liquid contact time, and reducing oxygen waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

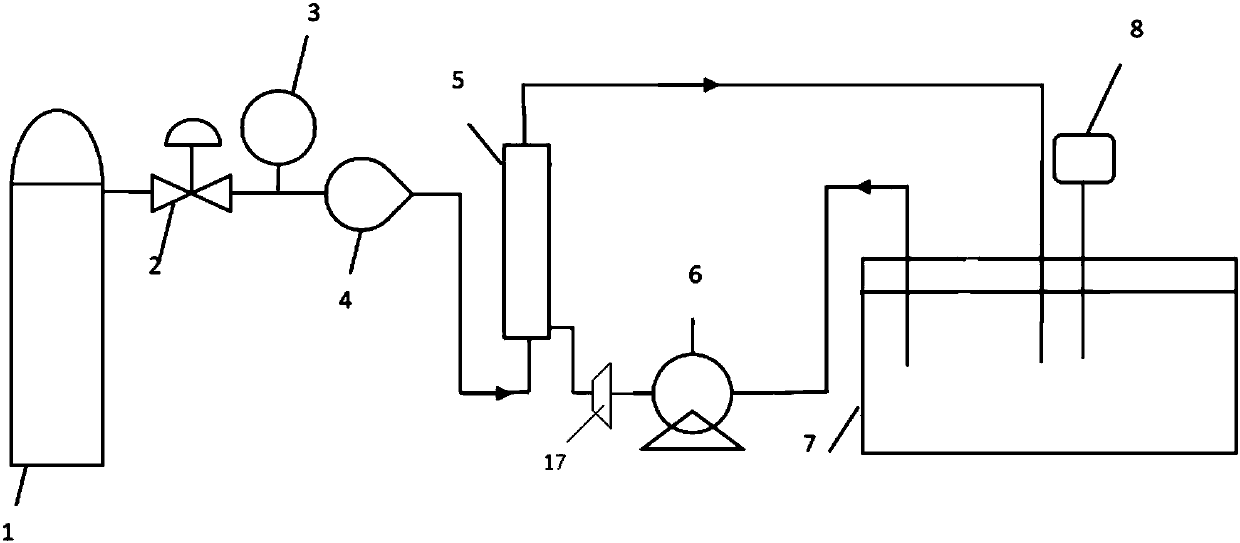

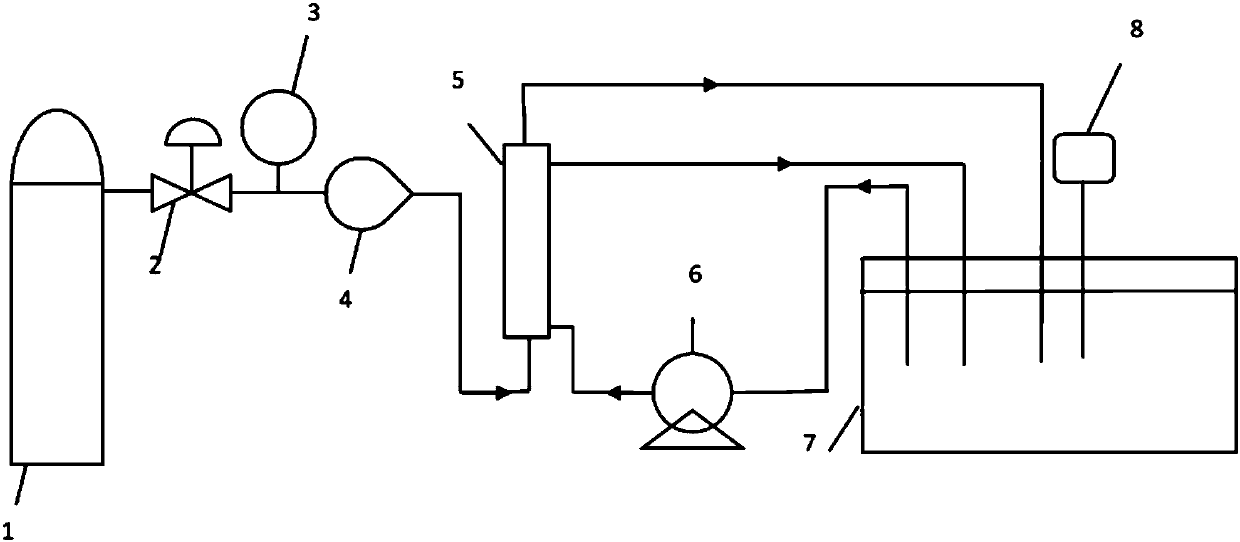

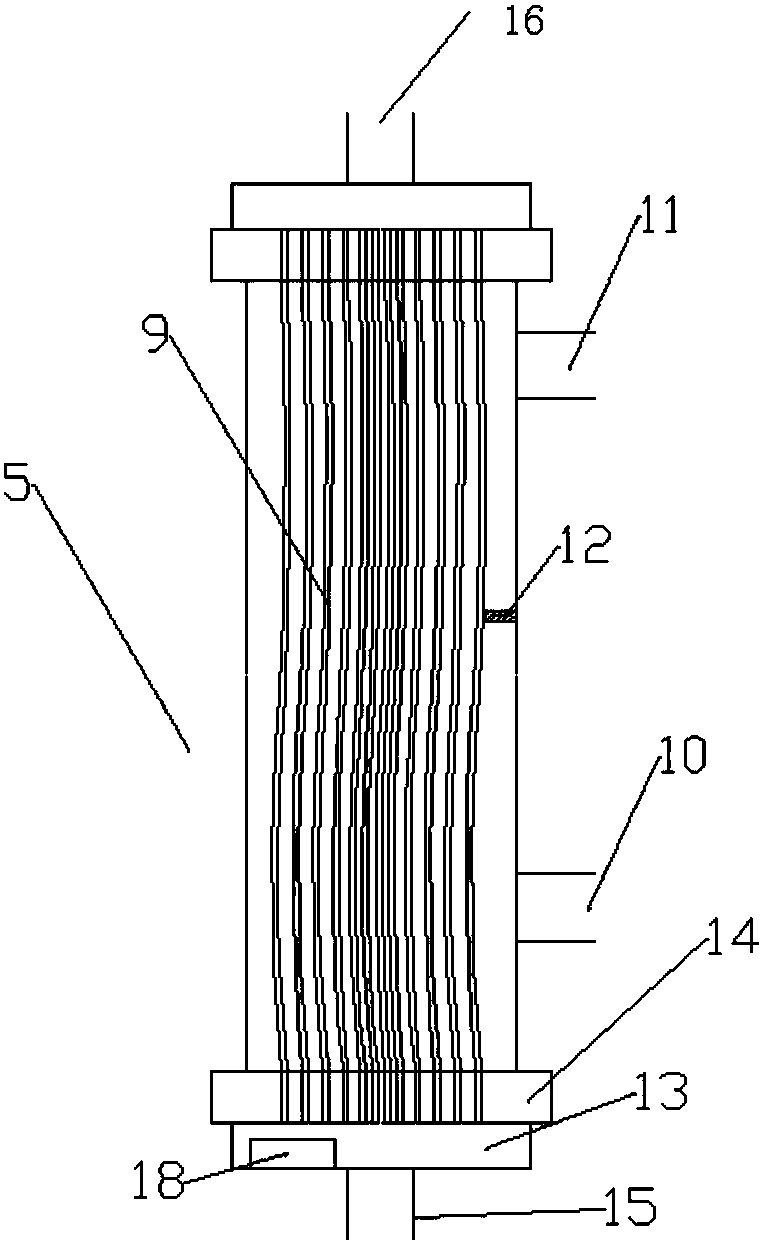

[0061] Such as figure 1 and image 3 As shown, the hollow fiber membrane module has a diameter of 2 inches, a length of 600mm, and a membrane filtration area of 1.2 m 2 . The membrane filament is made of polymer material PVDF by diffusion-induced phase inversion method, which has good filtration performance and mechanical strength. The inner diameter of a single membrane filament is 0.7mm, the outer diameter is 1.3mm, the most probable pore diameter is 25±2nm, accounting for more than 80%, and the largest pore is less than 50nm. The membrane with this pore size can better distribute oxygen and improve the efficiency of oxygen mass transfer.

[0062] During the oxygenation process, the hollow fiber membrane module 5 adopts an external pressure dead-end operation mode to improve the utilization rate of oxygen. Under the action of the pump, the water enters the shell layer of the membrane module through the water inlet, and penetrates into the inside of the membrane filamen...

Embodiment 2

[0067] Such as figure 1 and image 3 As shown in the device, the hollow fiber membrane module 5 has a diameter of 2 inches, a length of 600 mm, and a membrane filtration area of 1.2 m 2. The membrane filament is made of polymer material PVDF by diffusion-induced phase inversion method, which has good filtration performance and mechanical strength. The inner diameter of a single membrane filament is 0.7mm, the outer diameter is 1.3mm, the most probable pore diameter is 25±2nm, accounting for more than 80%, and the largest pore is less than 50nm. The membrane with this pore size can completely intercept solid pollutants and some macromolecular impurities in water.

[0068] During the filtration process, the water body enters the shell layer of the membrane module through the water inlet under the action of the pump, and the entering pressure is about 0.05MPa. Filtration of water bodies. The filtered water is discharged from the water outlet and enters the pool 7 again. T...

Embodiment 3

[0073] Such as figure 1 and image 3 In the device shown, clean water is used as the water source, and the device is composed as follows: oxygen source 1, gas regulating valve 2 and barometer 3 are connected by steel pipes; after passing through the gas flow meter 4, rubber hoses are used to connect the subsequent hollow fiber membrane module 5 . The transfer pump 6 (centrifugal pump) is connected to the pool through plastic water pipes; the hollow fiber membrane module 5 is connected to the pool 7 through rubber tubes, and water circulation is realized under the action of the pump. In addition, it is equipped with a dissolved oxygen detector 8 to detect the effect of increasing oxygen.

[0074] The working process is divided into two parts: water and air. Oxygen gas starts from the oxygen source 1, is controlled by the gas regulating valve 2, flows from the steel pipe through the barometer 3, and flows into the membrane module through the hose after being regulated by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com