Graphene modified polymer conducting fabric based on thermal reduction method and preparation method thereof

A polymer conductive and graphene technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of complex process, multiple processes, conductive fibers and conductive nanomaterials, etc., and achieve simple preparation method and operability Strong, good durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

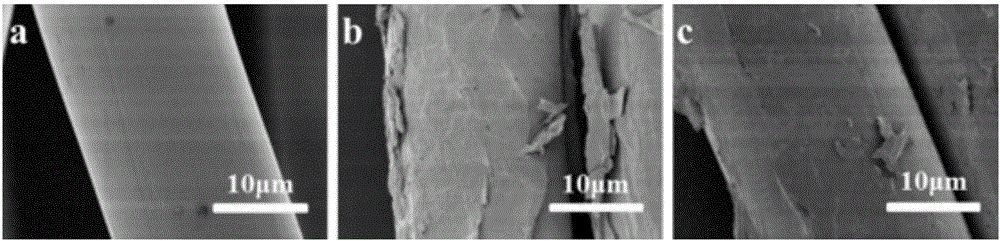

[0026] 0.5 g of graphene oxide was added to 50 g of a 50% ethanol aqueous solution by mass fraction to prepare a graphene oxide suspension. The polyphenylene sulfide fabric was soaked in the graphene oxide suspension for 5 minutes, and then the soaked polymer fabric was dried in a blast oven at 90°C for 5 minutes, and the above soaking-drying process was repeated 10 times. Put the high-temperature-resistant polymer fabric that has undergone the soaking-drying process in a tube furnaceN 2 Heating at 200° C. for 2 hours under the atmosphere, the graphene oxide is thermally reduced to graphene, that is, a polymer conductive fabric is prepared. The electrical conductivity of the fabric was 0.0133 S / cm. In this embodiment, the surface morphology before and after fabric modification is as follows figure 1 shown.

Embodiment 2

[0028] 1 g of graphene oxide was added to 50 g of an 80% aqueous acetic acid solution by mass fraction to prepare a graphene oxide suspension. The polyphenylene sulfide fabric was soaked in the graphene oxide suspension for 10 minutes, and then the soaked polymer fabric was dried in a blast oven at 90°C for 10 minutes, and the above soaking-drying process was repeated 5 times. Put the high-temperature-resistant polymer fabric that has undergone the soaking-drying process in a tube furnaceN 2 Heating at 250° C. for 3 hours under the atmosphere, the graphene oxide is thermally reduced to graphene, that is, a polymer conductive fabric is prepared. The electrical conductivity of the fabric was 0.0201 S / cm.

Embodiment 3

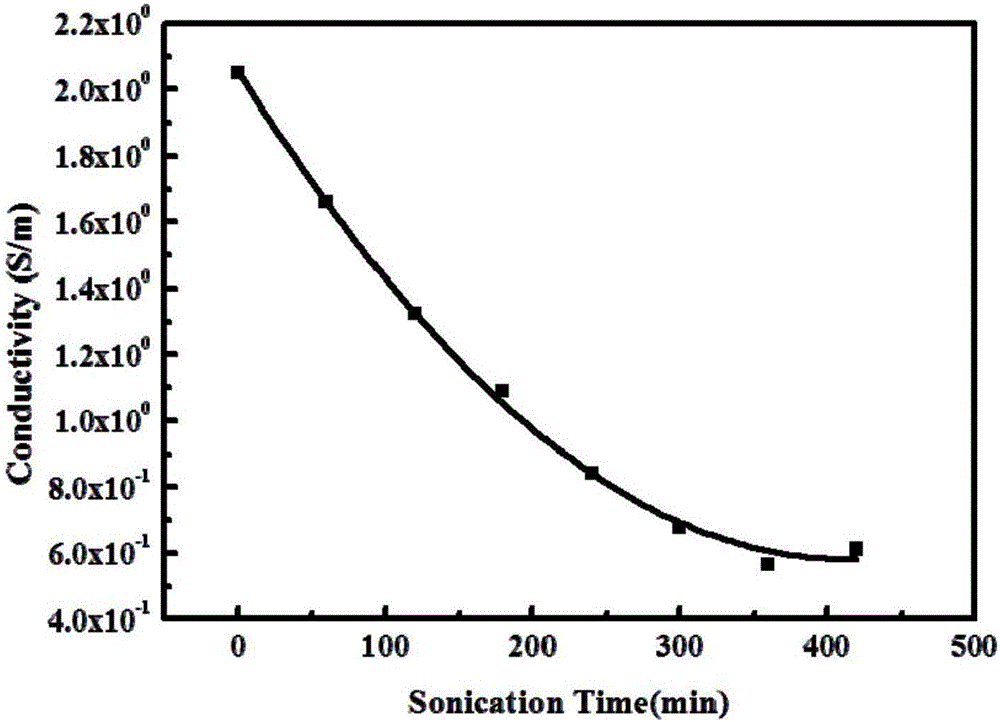

[0030] 1.5 g of graphene oxide was added to 50 g of acetone aqueous solution with a mass fraction of 60%, to prepare a graphene oxide suspension. The polyether ether ketone fabric was soaked in the graphene oxide suspension for 15 minutes, and then the soaked polymer fabric was dried in a blast oven at 90°C for 5 minutes, and the above soaking-drying process was repeated 10 times. Put the high-temperature-resistant polymer fabric that has undergone the soaking-drying process in a tube furnaceN 2 Heating at 280° C. for 3 hours in the atmosphere, thermally reducing graphene oxide to graphene, that is, preparing a polymer conductive fabric. The electrical conductivity of the fabric was 0.0213 S / cm. The good durability of this prepared fabric, after ultrasonic treatment 420min, electrical conductivity remains on 0.6S / m, and tends toward equilibrium (as figure 2 shown). The prepared fabrics, the yarns in which the mechanical properties remain unchanged at different reduction ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com