A kind of modified chitosan is used as raw material to prepare desulfurization and mercury removal agent and preparation method thereof

A chitosan and modification technology is applied in the field of preparing desulfurization and mercury removal agent and its preparation field by using modified chitosan as raw material, which can solve the problem that the sulfur component cannot be reasonably utilized, the metabolism of the organism is affected, and the cost of industrial application is high. problems, to achieve the effects of low cost, reduced component content, and rapid precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In some embodiments, modified chitosan is used as a raw material to prepare a method for preparing a desulfurization and mercury removal agent, comprising the following steps:

[0033] (1) Crush pyrolusite, grind it into powder, and place it in a microwave radiation treatment for 8-15 minutes with a radiation power of 130-180W, add water to form a slurry;

[0034] (2) Mix thiosemicarbazide and chitosan according to the mass ratio of 1:1.3-2.1, drop potassium periodate accounting for 0.3-1.1 times the mass of thiosemicarbazide, and stir evenly to obtain modified chitosan;

[0035] (3) Add the pulp to the modified chitosan, and add water to adjust the liquid-solid ratio to 3-7:1.

[0036] In some embodiments, in the step (1), after the pyrolusite is ground into powder, water is added to prepare it into a slurry, and then it is treated with microwave radiation for 8-15 minutes, and the radiation power is 130-180W.

[0037] In some embodiments, the preparation method can a...

Embodiment 1

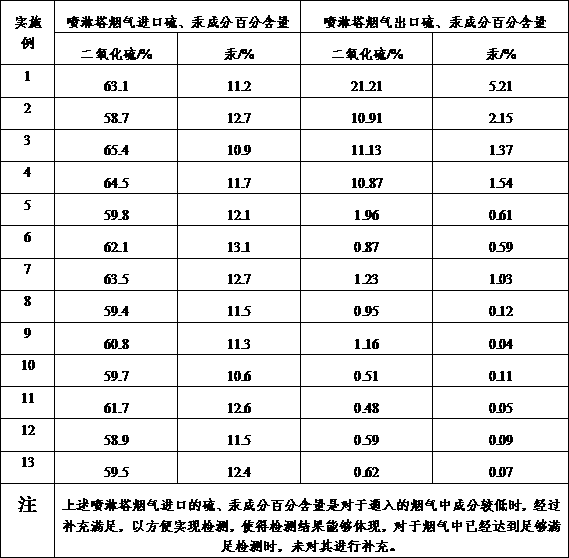

[0043] After the pyrolusite was crushed into powder, it was prepared into slurry by adding water with a liquid-solid ratio of 3:1, and it was used for desulfurization and demercuration of coal-fired flue gas in thermal power plants. The results are shown in Table 1.

Embodiment 2

[0045] After the pyrolusite is crushed into powder, it is prepared into slurry by adding water, the liquid-solid ratio is 3:1, and treated with microwave radiation for 15 minutes, the radiation power is 130W, and it is used for desulfurization and demercuration of coal-fired flue gas in thermal power plants treatment, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com