A kind of construction method of core-shell structure

A construction method and core-shell structure technology, which can be applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as limited degradability, incomplete degradation of silicon shells, and burden on the body , to achieve the effects of easy degradation, uniform particle size, and strong manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1 Nanoparticle ACC-HCPT loaded with ring-opened hydroxycamptothecin b 2 Preparation

[0076] Disperse 75.5 mg of anhydrous calcium chloride and 0.25 mL of water in 100 mL of ethanol, then put the resulting reaction solution into a 100 mL volume jar, seal it with a sealing film, and reserve a small hole; fill the ammonium bicarbonate Put it into a 20mL jar, seal it with a sealing film, and reserve a small hole; put the above-mentioned jar containing the reaction solution and the jar containing ammonium bicarbonate together in a vacuum desiccator, at 30°C Stand still for 12 hours under the environment; keep the obtained reaction solution in the jar, and directly add 0.25mL aqueous solution with composition of 8mg / mL hydroxycamptothecin and 32mg / mL sodium hydroxide; after stirring evenly, re-sealing Seal the mouth of the bottle with a film and reserve a small hole, then put the jar containing the reaction solution and the jar containing ammonium bicarbonate into a...

Embodiment 2

[0077] Example 2 Nanoparticles ACC-HCPT loaded with ring-opened hydroxycamptothecin b 6 preparation

[0078] Disperse 75.5 mg of anhydrous calcium chloride and 0.25 mL of water in 100 mL of ethanol, then put the resulting reaction solution into a 100 mL volume jar, seal it with a sealing film, and reserve a small hole; fill the ammonium bicarbonate Put it into a 20mL jar, seal it with a sealing film, and reserve a small hole; put the above-mentioned jar containing the reaction solution and the jar containing ammonium bicarbonate together in a vacuum desiccator, at 30°C Stand still for 12 hours under the environment; keep the obtained reaction solution in the jar, and directly add 0.25mL aqueous solution with composition of 24mg / mL hydroxycamptothecin and 32mg / mL sodium hydroxide; after stirring evenly, re-sealing Seal the mouth of the bottle with a film and reserve a small hole, then put the jar containing the reaction solution and the jar containing ammonium bicarbonate into...

Embodiment 3 2

[0079] Example 3 Preparation of Nanoparticles HCPT2@silica15 Coated with Silica and Loaded with Hydrophobic Drug Hydroxycamptothecin

[0080] The nanoparticles ACC-HCPT loaded with ring-opening hydroxycamptothecin prepared in Example 1 b 2 Disperse in 20mL ethanol solution, add 0.4mL ammonia water, 300μg EDTA, 15μL tetraethyl orthosilicate and 0.4mL water in sequence, and stir for 24 hours; Amorphous calcium carbonate-ring-opened hydroxycamptothecin nanoparticles ACC-HCPT with silica shell b 2 @silica15.

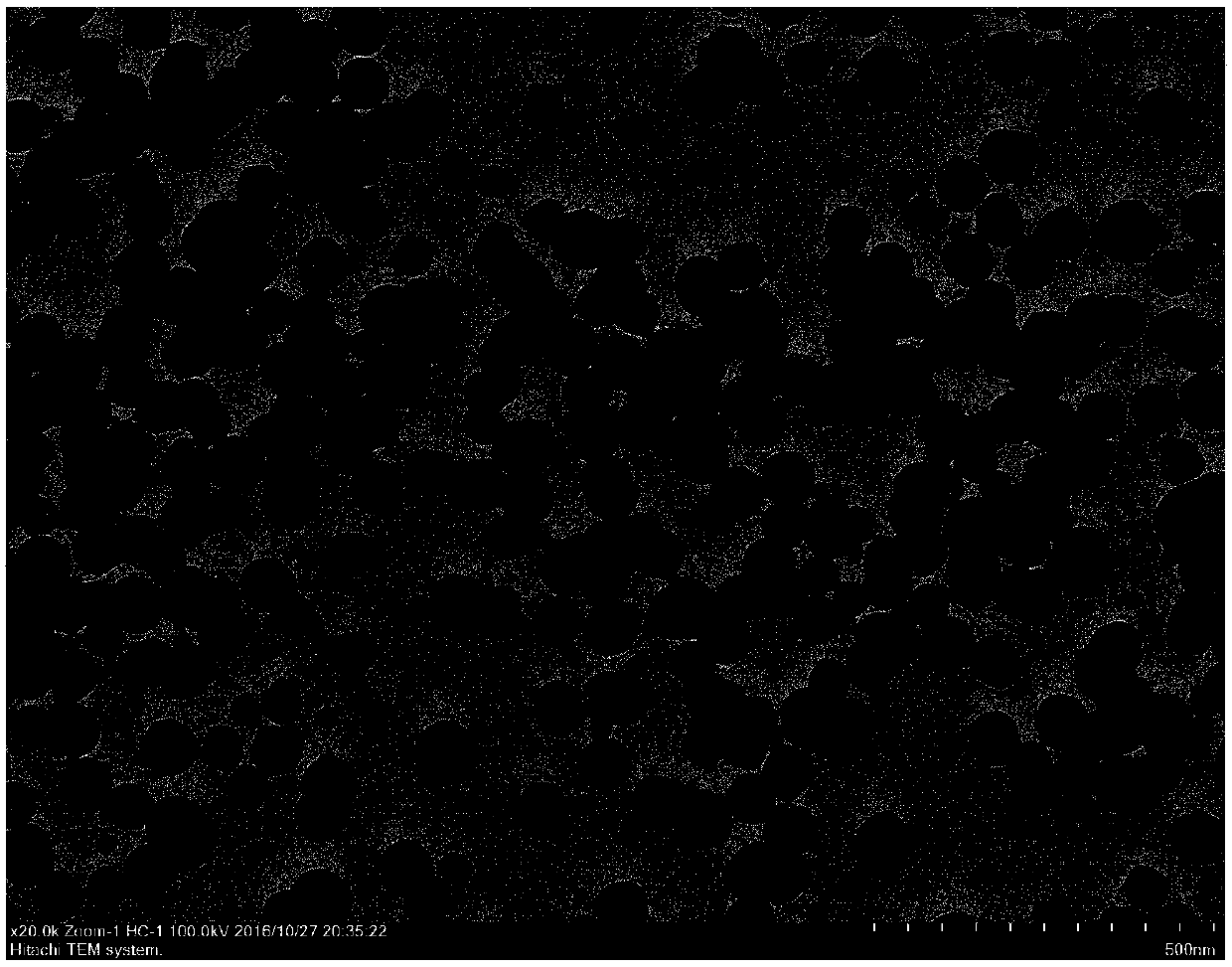

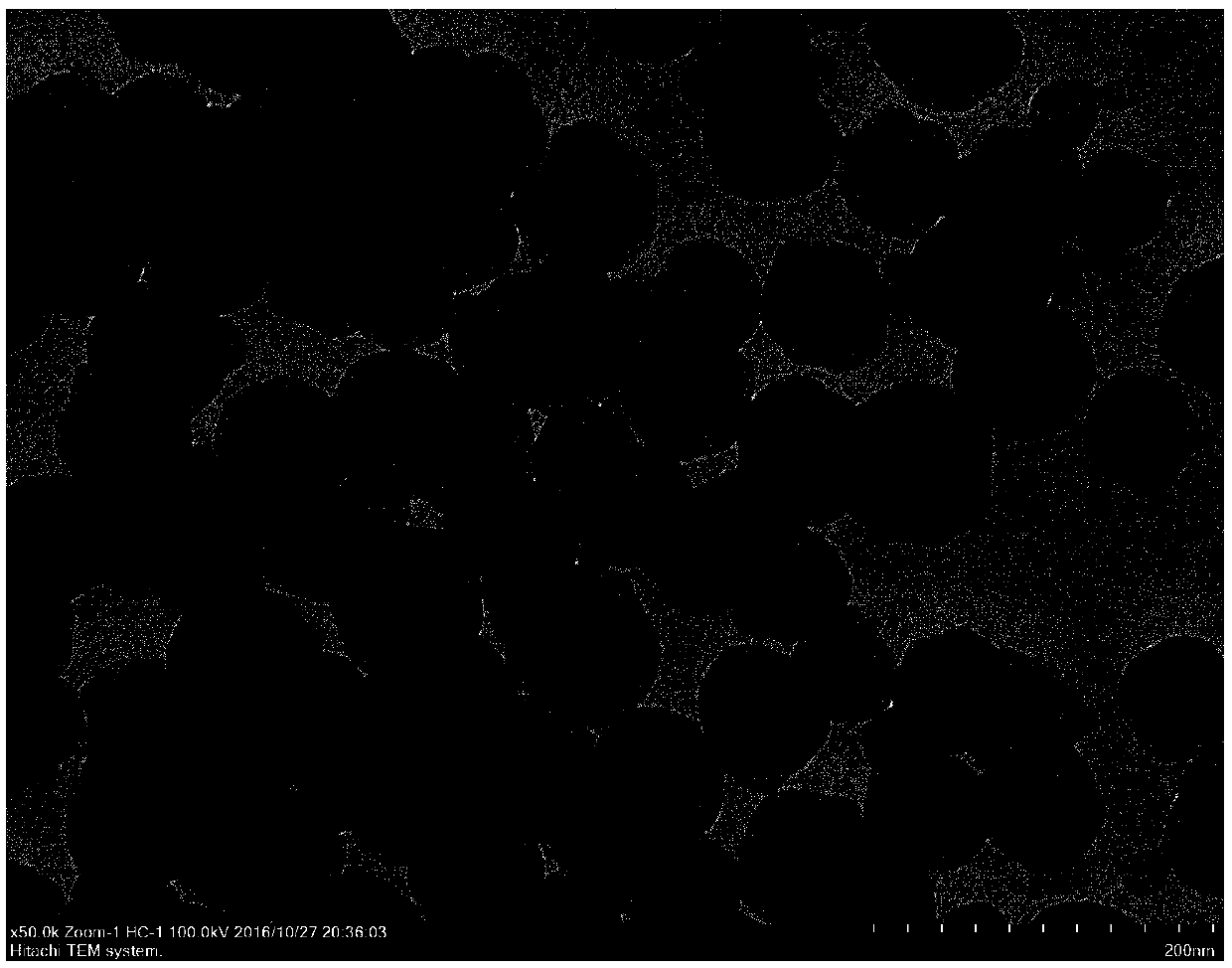

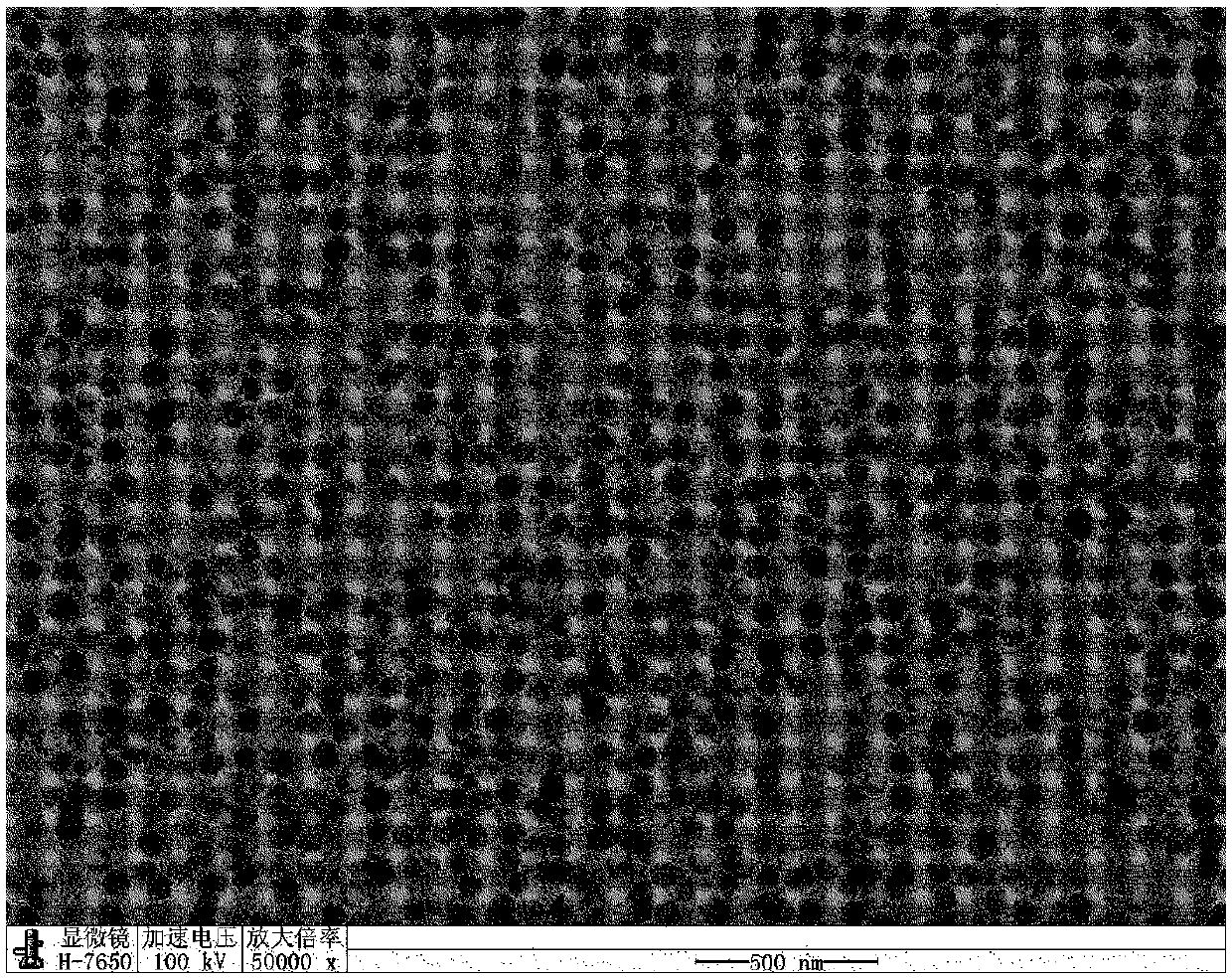

[0081] The above ACC-HCPT b 2@silica15 was dispersed in 5 mL of dilute hydrochloric acid with a concentration of 3.7%, centrifuged after standing for 2 hours, and the precipitate was washed with deionized water to obtain silica-coated nanoparticles HCPT2 loaded with hydrophobic drug hydroxycamptothecin @silica15. The appearance of the product is as Figure 5 , Figure 6 As shown, the particle size is uniform, about 110nm, in a monodisperse state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com