Method for preparing nitrogen-doped TiO2 hollow nano material

A hollow nanometer, nitrogen-doped technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as limiting the efficiency of sunlight utilization, achieve good repeatability, Visible light absorption spectrum and the effect of visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

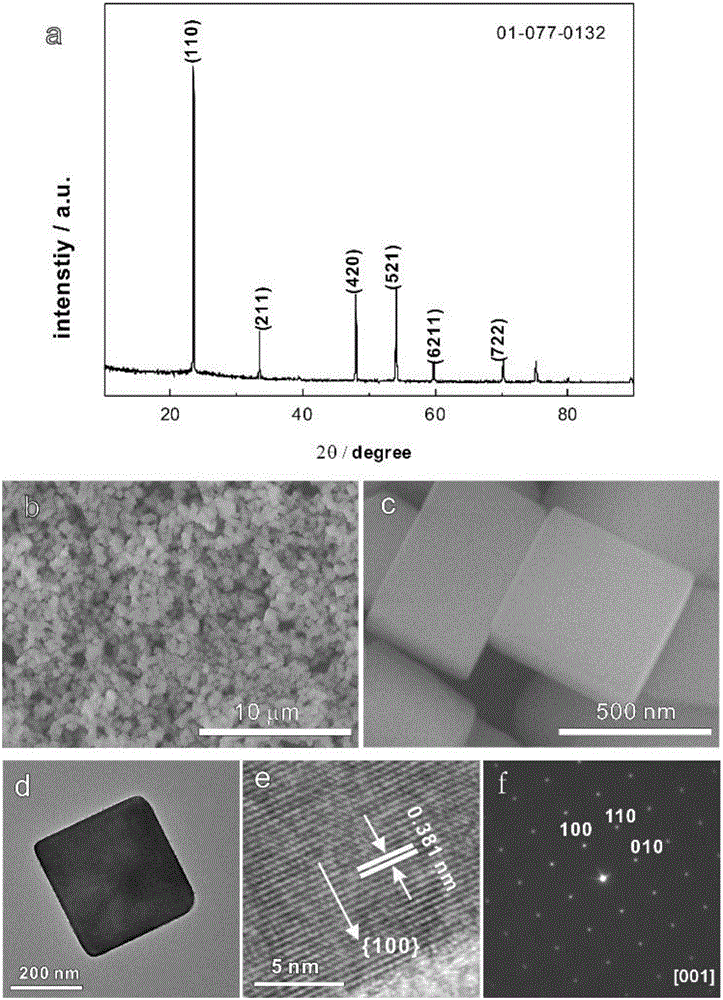

[0025] (1)TiOF 2 Fabrication of nanocubes: synthesis of TiOF by one-step solvothermal reaction 2 nanocube. Add 5.0 mL of tetrabutyl titanate, 1.6 mL of hydrofluoric acid solution and 10 mL of glacial acetic acid into the hydrothermal reaction kettle together. The reaction kettle was sealed and placed in an oven. The reaction temperature was heated from room temperature to 200° C. within 60 minutes, and then the reaction was maintained at 200° C. for 12 hours. After the reaction was over, the reactor was cooled to room temperature. Ultrasonic cleaning with ethanol and centrifugation to obtain white TiOF 2 Nanocube powder, whose composition and structure are characterized as figure 1 shown.

[0026] (2)TiOF 2 The nano-cube powder and urea were weighed and put into two porcelain boats respectively. TiOF 2 The used mass of nanocube is 0.4g, and the mass of urea weighed is 0.1g. Place the two porcelain boats with weighed samples in the middle of the tube furnace one by on...

Embodiment 2

[0029] (1)TiOF 2 The preparation of nanocubes is consistent with that of Example 1.

[0030] (2)TiOF 2 The nanocube and urea scales were taken out and put into two porcelain boats respectively. TiOF 2 The used mass of nanocube is 0.4g, and the mass of urea weighed is 0.25g. Place the two porcelain boats with weighed samples in the middle of the tube furnace one by one, use a vacuum pump to remove the gas in the tube, and then seal the tube furnace. In a sealed state, calcined at 500°C for 10h. After cooling to room temperature, the samples in the porcelain boat were collected to obtain the product.

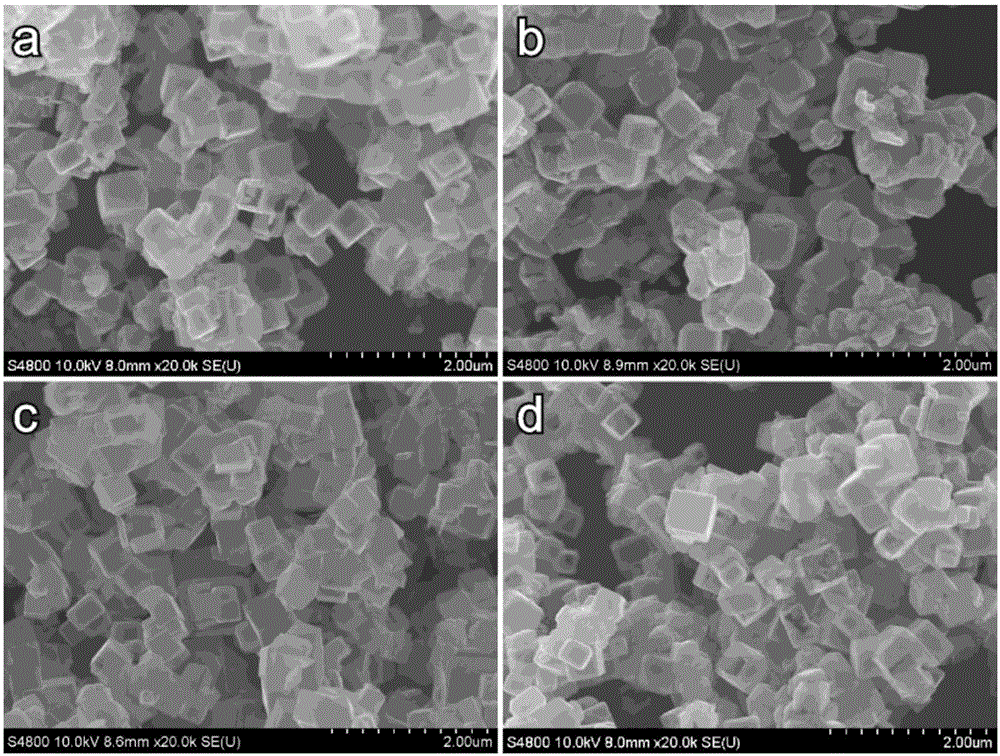

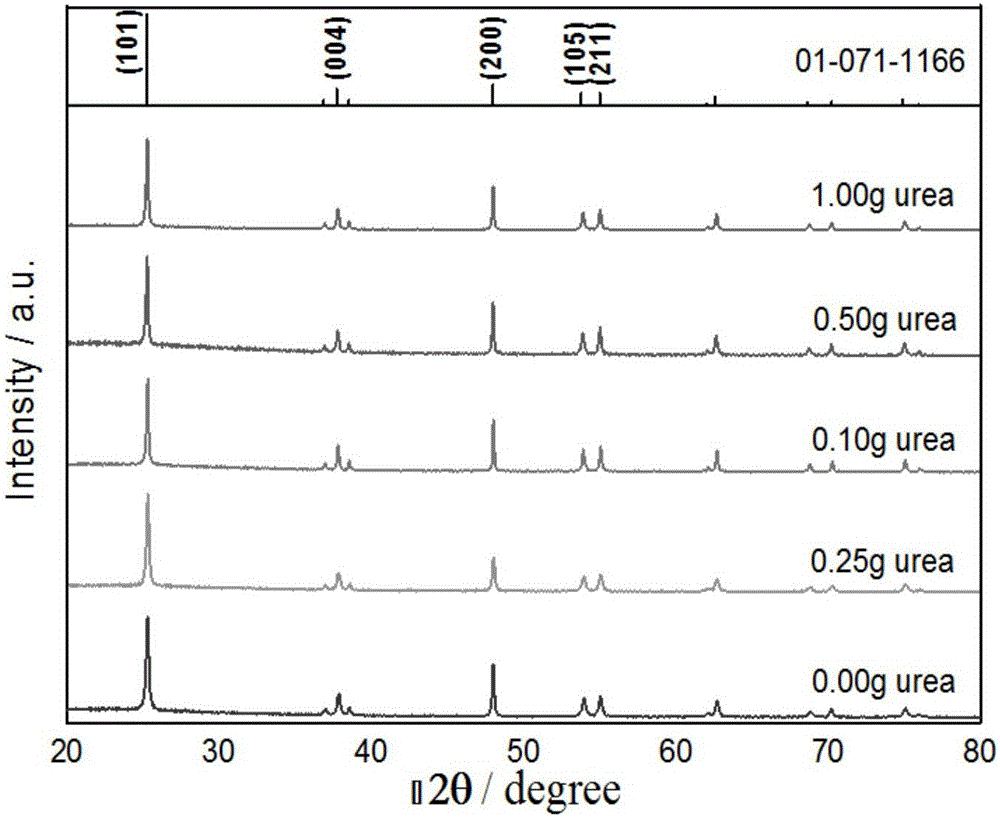

[0031] refer to figure 2 b. image 3 , the product is characterized by SEM, TEM, XRD as hollow TiO 2 Nano cubic box structure, the size is about 400-500nm. It can be seen through the solid powder ultraviolet-visible absorption spectrum (such as Figure 5 c), the absorption range of the product to visible light is broadened. The signal of N1s in the XPS spectrum is also...

Embodiment 3

[0033] (1)TiOF 2 The preparation of nanocubes is consistent with that of Example 1.

[0034] (2) Sample TiOF 2 The nanocube and urea scales were taken out and put into two porcelain boats respectively. TiOF 2 The mass of the nanocube is 0.4g, and the mass of urea is 0.50g. Place the two porcelain boats with weighed samples in the middle of the tube furnace one by one, use a vacuum pump to remove the gas in the tube, and then seal the tube furnace. In a sealed state, calcined at 600°C for 12h. After cooling to room temperature, the samples in the porcelain boat were collected to obtain the product.

[0035] refer to figure 2 c and image 3 , the product is characterized by SEM, TEM, XRD as hollow TiO 2 Nano cubic box structure, the size is about 400-500nm. It can be seen through the solid powder ultraviolet-visible absorption spectrum (such as Figure 5 d), the absorption range of the product to visible light is broadened, which is wider than the two products with le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com