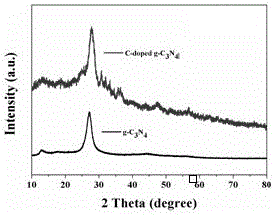

Carbon-doped graphite-phase carbon nitride nanotube and preparation method thereof

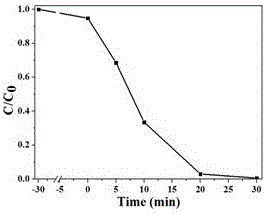

A technology of graphite phase carbon nitride and nanotubes, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of single morphology, achieve low cost and good application prospects , The effect of novel and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

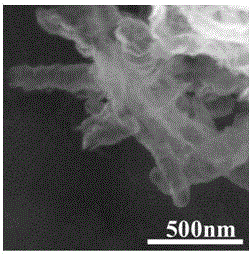

[0034] 1.1 Disperse 0.75g of melamine in 80ml of ethanol solution containing 8μL of aminopropyltrimethoxysilane (APS) in a 100mL reactor, heat it under water at 200°C for 24 hours, then centrifuge and dry to obtain a solid powder;

[0035] 1.2 Add 2 μL (3-mercaptopropyl)trimethyloxysilane (MPS) solution to 0.5mL Tetraethylsilicate (TEOS), stir well to obtain a homogeneous solution A;

[0036] 1.3 Mix 50mL ethanol and 5mL water and stir evenly to obtain solution B;

[0037] 1.4 Add solution A obtained in step 1.2 to solution B obtained in step 1.3, stir for 6 hours, and centrifuge to obtain a precipitate;

[0038] 1.5 Disperse the precipitate obtained in step 1.4 in 30 mL of water again, then add 1.2 g of treated melamine solid powder obtained by repeating step 1.1 several times, stir evenly, centrifuge, wash and dry to obtain a white solid powder, the powder Placed in a quartz boat and calcined at 580°C for 2h in nitrogen with a heating rate of 5°C / min to obtain the product; ...

Embodiment 2

[0042] 2.1 Disperse 1.2g melamine in 80ml ethanol solution containing 20μL APS in a reaction kettle with a volume of 100mL, heat in water at 220°C for 24h, centrifuge and dry to obtain a solid powder;

[0043]2.2 Add 5 μL of (3-mercaptopropyl)trimethyloxysilane (MPS) solution to 0.5 mL of tetraethyl orthosilicate (TEOS), stir well to obtain a uniform solution A;

[0044] 2.3 Mix 50mL ethanol and 10mL water and stir evenly to obtain solution B;

[0045] 2.4 Add solution A obtained in step 1.2 to solution B obtained in step 1.3, stir for 6 hours, and centrifuge to obtain a precipitate;

[0046] 2.5 Disperse the precipitate obtained in step 1.4 in 30 mL of water again, then add 1.5 g of treated melamine solid powder obtained by repeating step 2.1 several times, stir evenly, centrifuge, wash and dry to obtain a white solid powder, and the powder Placed in a quartz boat and calcined at 600°C for 2h in nitrogen with a heating rate of 5°C / min to obtain the product;

[0047] 2.6 Etc...

Embodiment 3

[0050] 3.1 Disperse 1.5g of melamine in 80ml of ethanol solution containing 10μL of APS in a 100mL reactor, heat it in water at 200°C for 24 hours, then centrifuge and dry to obtain a solid powder;

[0051] 3.2 Add 10 μL of (3-mercaptopropyl)trimethyloxysilane (MPS) solution to 1 mL of tetraethyl orthosilicate (TEOS), stir well to obtain a uniform solution A;

[0052] 3.3 Mix 100mL ethanol and 12mL water and stir evenly to obtain solution B;

[0053] 3.4 Add solution A obtained in step 1.2 to solution B obtained in step 1.3, stir for 6 hours, and centrifuge to obtain a precipitate;

[0054] 3.5 Disperse the precipitate obtained in step 1.4 in 50 mL of water again, then add 1.4 g of treated melamine solid powder obtained by repeating step 2.1 several times, stir evenly, centrifuge, wash and dry to obtain a white solid powder, the powder Placed in a quartz boat and calcined at 560°C for 2h in nitrogen with a heating rate of 5°C / min to obtain the product;

[0055] 3.6 Etch the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com