Polyester resin for high-temperature-resisting powdered paint and preparation method of polyester resin

A polyester resin, powder coating technology, applied in powder coatings, fire-retardant coatings, polyester coatings, etc., to achieve the effect of cost saving, less processing, and high gloss retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

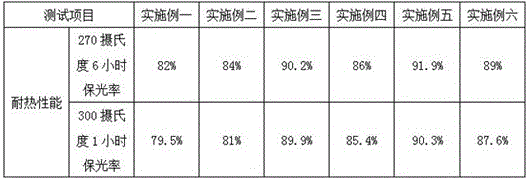

Examples

Embodiment 1

[0043] A polyester resin for high-temperature-resistant powder coatings, the polyester resin includes the following raw materials in parts by weight:

[0044] Neopentyl glycol 15 parts

[0045] 1,2-propanediol 2 parts

[0046] 2 parts of 2-methyl-1,3-propanediol

[0047] 35 parts of terephthalic acid

[0048] 10 parts of isophthalic acid

[0049] 2 parts adipic acid

[0050] 35 parts of trimethylolpropane

[0051] Trimethylolethane 40 parts

[0052] Tris (2-hydroxyethyl) isocyanurate 0.5 parts

[0053] Catalyst 1 part

[0054] Antioxidant 0.3 parts

[0055] Accelerator 0.2 part.

[0056] In the present embodiment, catalyzer is monobutyl tin oxide, and promotor is tetrabutyl ammonium chloride, and antioxidant comprises antioxidant 3114 and antioxidant 168, and the mass ratio of antioxidant 3114 and antioxidant 168 is 1:2.

Embodiment 2

[0058] A polyester resin for high-temperature-resistant powder coatings, the polyester resin includes the following raw materials in parts by weight:

[0059] Neopentyl glycol 40 parts

[0060] 10 parts of 1,2-propanediol

[0061] 10 parts of 2-methyl-1,3-propanediol

[0062] 45 parts of terephthalic acid

[0063] 25 parts of isophthalic acid

[0064] 7 parts of adipic acid

[0065] 80 parts of trimethylolpropane

[0066] 70 parts of trimethylolethane

[0067] Tris(2-hydroxyethyl)isocyanurate 2 parts

[0068] Catalyst 3 parts

[0069] Antioxidant 0.8 parts

[0070] Accelerator 0.7 parts.

[0071] In the present embodiment, the catalyst is dibutyltin oxide, the promotor is ethyltriphenylphosphine bromide, the antioxidant includes antioxidant 3114 and antioxidant 168, and the quality of antioxidant 3114 and antioxidant 168 The ratio is 2:1.

Embodiment 3

[0073] A polyester resin for high-temperature-resistant powder coatings, the polyester resin includes the following raw materials in parts by weight:

[0074] Neopentyl glycol 25 parts

[0075] 1,2-propanediol 6 parts

[0076] 6 parts of 2-methyl-1,3-propanediol

[0077] 40 parts of terephthalic acid

[0078] 18 parts of isophthalic acid

[0079] 5 parts of adipic acid

[0080] Trimethylolpropane 55 parts

[0081] Trimethylolethane 55 parts

[0082] Tris (2-hydroxyethyl) isocyanurate 1.3 parts

[0083] Catalyst 2 parts

[0084] Antioxidant 0.5 parts

[0085] Accelerator 0.5 parts.

[0086] In this embodiment, the catalyst is monobutyltin oxide, the promotor is tetrabutylammonium chloride, the antioxidant includes antioxidant 3114 and antioxidant 168, and the mass ratio of antioxidant 3114 to antioxidant 168 is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com