Preparation method of silicone rubber foam with controllable multi-scale pore structure

A technology of silicone rubber and pore structure, applied in manufacturing, additive processing, liquid material additive processing and other directions, can solve the problems of less involved in rubber foam printing, and achieve low cost, widened control space, and simple process equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

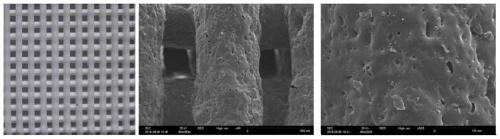

Embodiment 1

[0031] Mix 100g of terminal vinyl polydimethylsiloxane with a viscosity of 1500mPa.s, 70g of gas-phase method hydrophobic silica, and 5g of zinc oxide with a stirring device, and then add 120g of micron sodium chloride particles obtained by grinding, 5g Polyethylene glycol with a molecular weight of 1000, 7g hydrogen-containing silicone oil with a hydrogen weight fraction of 7%, and 0.3g platinum-vinylsiloxane complex are mixed uniformly with a stirring device at room temperature; After defoaming treatment, package it in the pressure injection system of a 3D printer (the 3D printer used is the shotmaster 350PC of MUSASHI, and other qualified 3D printers can also be used), install a pressure injection needle with an inner diameter of 0.6mm, and inject the pressure After the system is loaded on the mobile control system of the 3D printer, start the printing pressure and movement program, adjust the printing pressure and movement speed, so that the printing line width is 0.8 times...

Embodiment 2

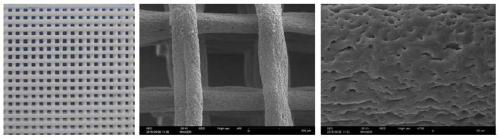

[0033]Mix 100g of terminal vinylmethylphenyl silicone rubber with a viscosity of 5000mPa.s, 10g of fumed hydrophilic silica, 40g of fumed hydrophobic silica, and 5g of zinc oxide with a stirring device, and then add high-speed stirring to obtain 100g micron urea particles, 10g molecular weight is the polyethylene glycol of 400, 10g hydrogen weight fraction is the hydrogen-containing silicone oil of 4%, 0.8g polyvinyl polysiloxane and 0.2gPt mass fraction are the platinum catalyst of 1%, in Mix evenly with a stirring device in an environment of 10-20°C; after degassing the above rubber materials with a centrifuge, package them in the pressure injection system of the 3D printer, install a pressure injection needle with an inner diameter of 0.25mm, and load the pressure injection system After the mobile control system of the 3D printer, start the printing pressure and movement program, adjust the printing pressure and movement speed, so that the printing line width is 0.95-1.1 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com