Environment-friendly water-resistant antibacterial putty powder and preparation method thereof

A technology of putty powder and antibacterial powder, which is applied in the direction of filling slurry, etc., can solve the problems of not satisfying consumers and greatly affecting the wall surface, and achieve the effects of being beneficial to the health of the family, good plasticity, and relieving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

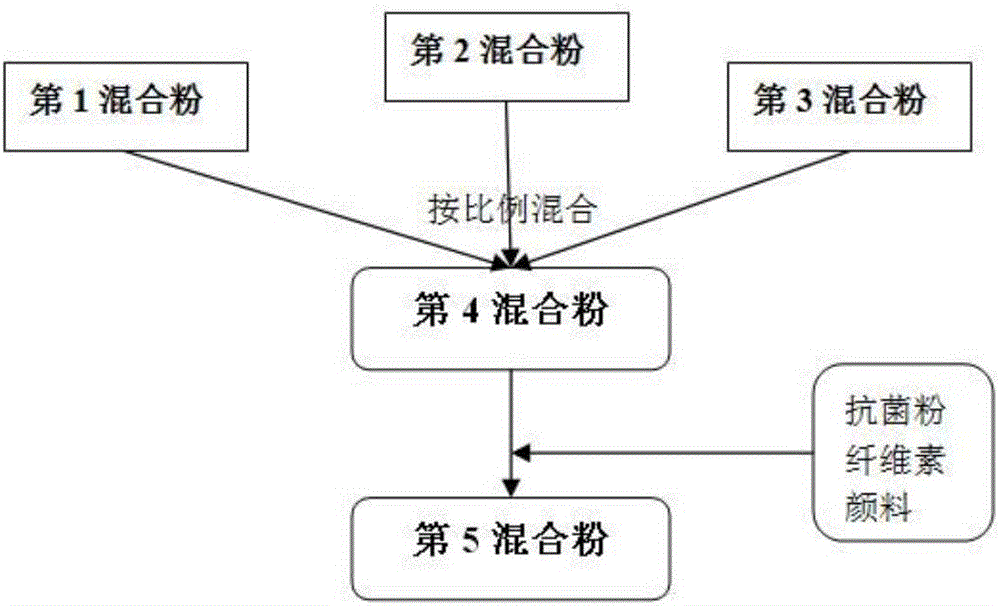

[0025] figure 1 It is a process flow chart of the preparation method of the antibacterial powder used in the environmental protection, water-resistant and antibacterial putty powder proposed by the present invention. The preparation method of the antibacterial powder comprises the following steps:

[0026] An antibacterial and antioxidant additive, the additive comprises hemicellulose, chitosan oligosaccharide, iron ion and montmorillonite polymerized, and its preparation method comprises the following steps:

[0027] S1. Preparation of chitosan oligosaccharide-iron complex: take chitosan oligosaccharide and dissolve it in 1.5% acetic acid solution (1.5%, v / v), add appropriate amount of FeSO under magnetic stirring conditions 4 ·7H 2 O powder, use 5g / L sodium acetate to adjust the pH to 6.0, keep stirring for 10-12h to balance, add a mixture of acetone:ethanol:isoamyl alcohol with a volume ratio of 25:24:1, and obtain a lumpy precipitate; vacuum pump The precipitate was sepa...

experiment example 1

[0039] The mensuration of experimental example 1 antibacterial and antioxidant additive reducing power

[0040] The antibacterial and antioxidant additives used in the present invention are compared with hemicellulose, chitosan and the commonly used antioxidant BTH to measure the reducing power of several substances and compare their antioxidant properties;

[0041] Take 1.0mL of the sample to be tested and place it in a test tube, add 2.0mL of deionized water and 2.0mL of 10% (w / v) K 3 Fe(CN) 6 The solution was mixed evenly, kept at 60°C for 30min, then placed in the refrigerator for rapid cooling at 4°C, added 1.0mL of 20% (w / v) trichloroacetic acid solution, mixed and centrifuged at 4000r / min for 15min. Take 3 mL of the supernatant and add distilled water and 1.0 mL of 0.2% (w / v) FeCl 3 , mix evenly, measure the absorbance at 700nm after standing for 10min, the greater the absorbance, the stronger the reducing ability of the sample to be tested, that is, the better the an...

experiment example 2

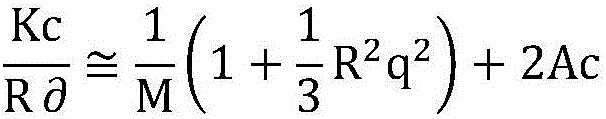

[0045] Experimental example 2 putty powder water absorption of the present invention is measured

[0046] Take a certain amount of sample and dry it in vacuum at 60°C, weigh every 1h until the quality of the sample does not change, take 0.2g sample and immerse it in 100ml deionized water or 0.75% sodium chloride solution at room temperature , when the adsorption reaches equilibrium, the sample is filtered from a 100-mesh sieve, and each treatment is repeated 3 times, and the test results are shown in Table 2; the water absorption is calculated by the following formula; where, Q-sample water absorption; Ws - dry weight of the sample; Wd - swollen weight of the sample.

[0047]

[0048] Table 2 Determination of water absorption of putty powder

[0049] Soak objects water absorption Deionized water 1657% 0.75% sodium chloride solution 935%

[0050] The experimental data in Table 2 shows that the water absorption of the putty powder of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com