A preparation method of multi-level structure tungsten particle reinforced aluminum matrix composite material

A particle-reinforced aluminum and composite material technology, used in metal processing equipment, coating, transportation and packaging, etc., can solve the problem of inability to obtain dense tungsten particle-reinforced aluminum matrix composite materials, limit the application of composite materials, and affect the strength of composite materials. and other problems, to achieve the effect of realizing large-scale industrial application production, improving interface bonding and improving interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the multi-level structure tungsten particle reinforced aluminum matrix composite material is composed of 50% tungsten and 50% aluminum matrix in mass percentage, and the preparation method steps of the tungsten particle reinforced aluminum matrix composite material are as follows:

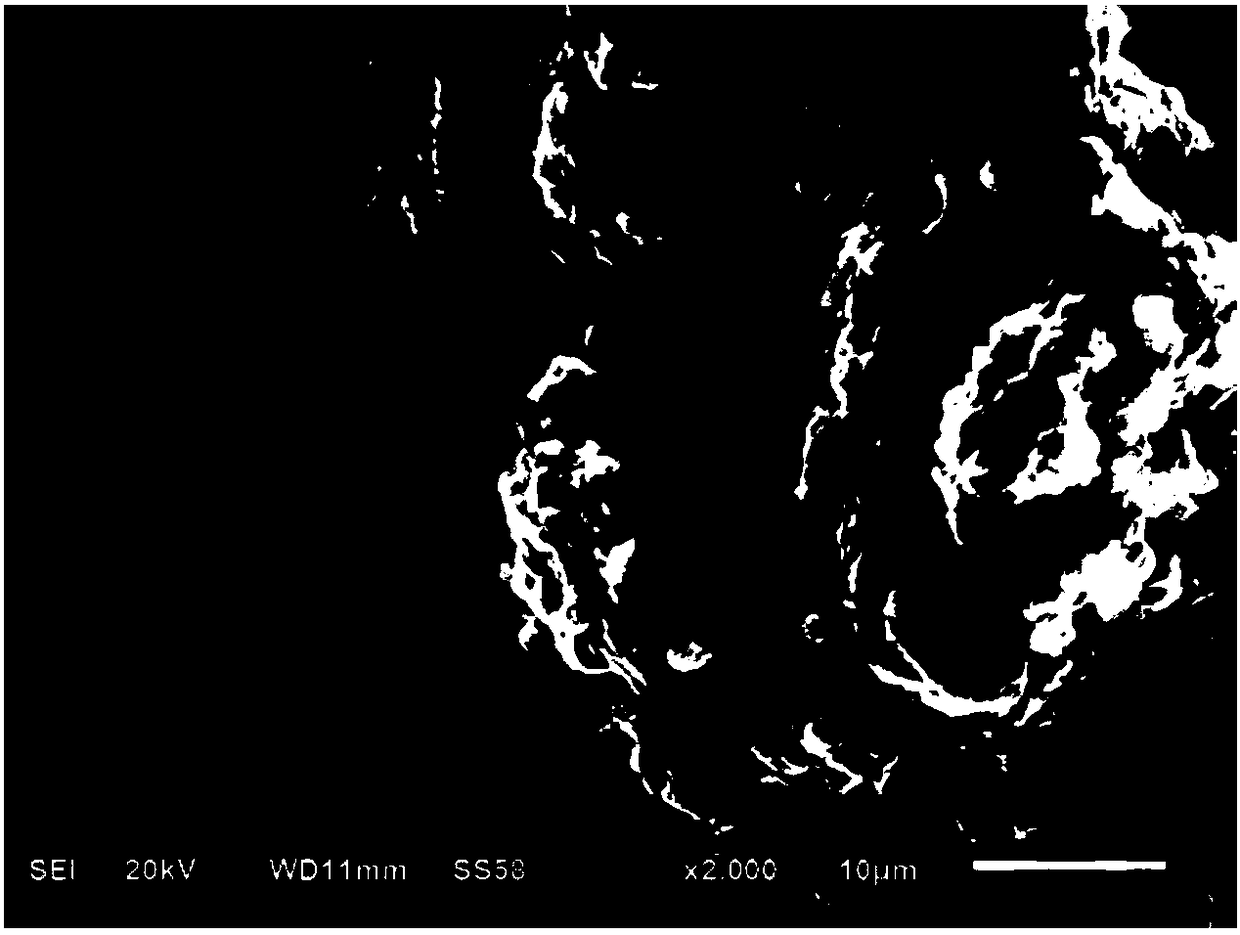

[0027] (1) Weigh 400g of tungsten powder, 200g of aluminum powder, and 3kg of stainless steel grinding balls, and use a planetary ball mill in an argon-protected environment to carry out ball milling at a speed of 400 rpm for 8 hours to obtain Al Coated W particle cluster composite powder;

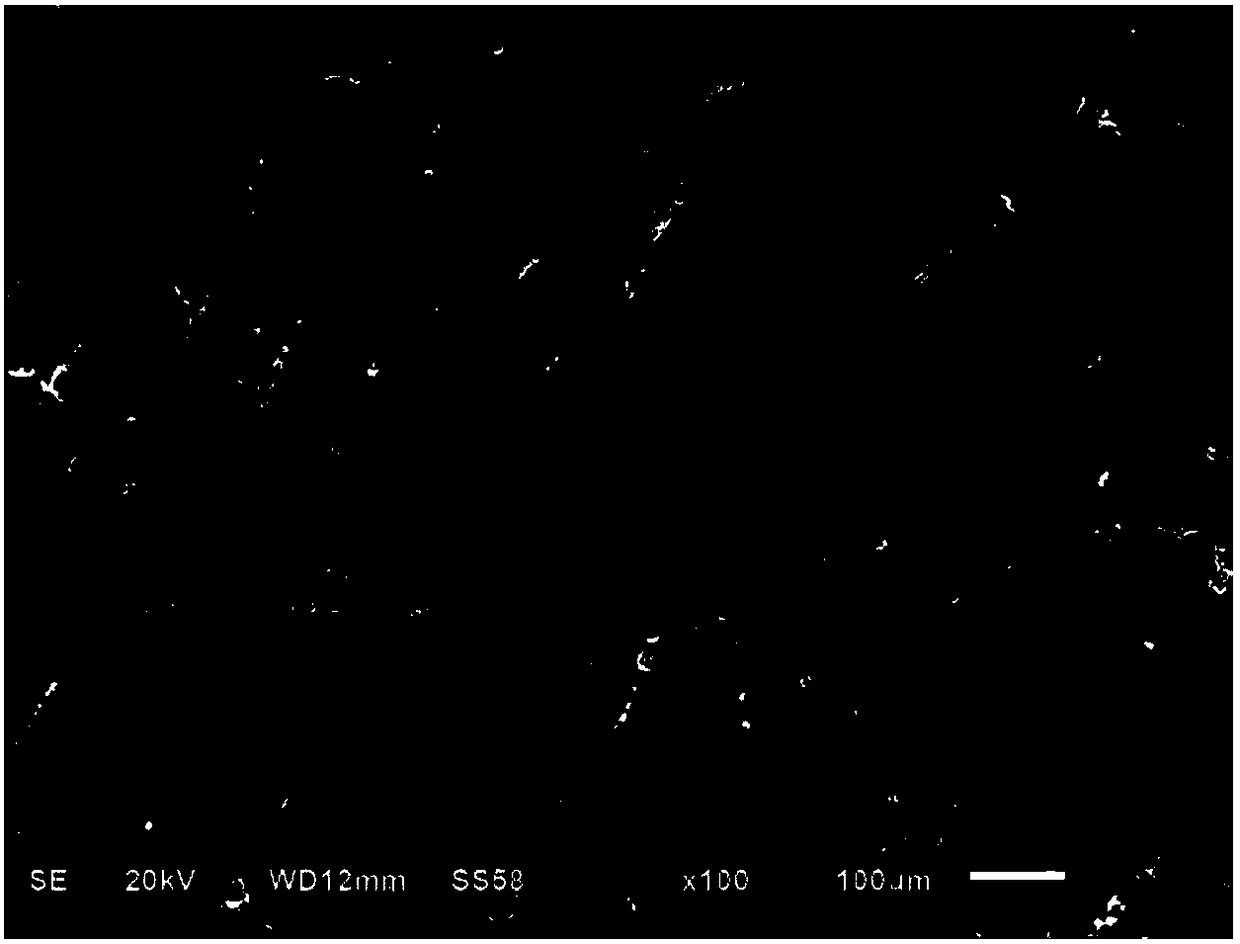

[0028] (2) Weigh 750g of Al-coated W particle cluster composite powder and 250g of aluminum powder in step (1), and use a double-cone mixer to mix the materials under the protection of argon, and the weight ratio of the grinding ball to the powder is The ratio is 1:1, and the mixing time is 8h to obtain a composite powder;

[0029] (3) Put the composite powder in step (2) in the pref...

Embodiment 2

[0033] The steps are the same as in Example 1, except that the quality of the tungsten powder in step (1) is 480g, and that of the aluminum powder is 120g.

[0034] The density of the obtained composite material is 99.9%, the tensile strength at room temperature is 315MPa, the bending strength at room temperature is 476MPa, the yield strength at room temperature is 205MPa, and the elongation is 6%.

Embodiment 3

[0036] The procedure is the same as in Example 1, except that the weight of the Al-coated W particle cluster composite powder weighed is 700 g, and the weight of the aluminum powder is 300 g.

[0037] The hot isostatic pressing temperature was changed from 520°C to 550°C.

[0038] The density of the obtained composite material is 99.7%, the tensile strength at room temperature is 310MPa, the bending strength at room temperature is 520MPa, the yield strength at room temperature is 200MPa, and the elongation is 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com