Preparation method of pvdf copolymer ceramic coated diaphragm

A copolymer and ceramic coating technology, which is applied in the direction of separators/films/diaphragms/spacers, structural parts, electrical components, etc., can solve the problem of large specific surface area of ceramic particles and whiskers, reducing the thermal shrinkage rate of lithium battery diaphragms, Lithium battery pole pieces are not bonded firmly and other problems, to achieve the effect of improving liquid absorption rate, increasing rate and cycle performance, and not easy to disperse and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

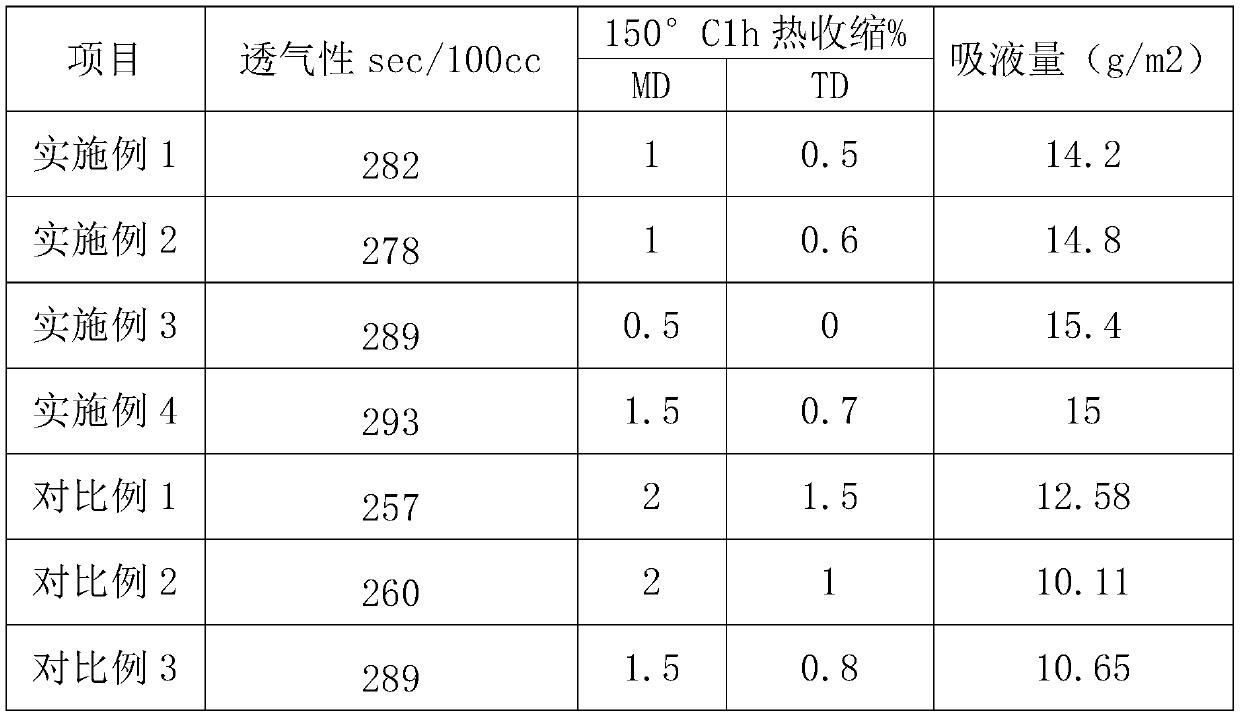

Examples

Embodiment 1

[0022] A preparation method for a PVDF copolymer ceramic coating diaphragm, comprising the following steps:

[0023] 1) Preparation of ceramic slurry: 170g of deionized water, 20g of Al2O3 powder, and 10g of PVAC were mixed and stirred, and ball milled in a ball mill for 1-3 hours to obtain a ceramic slurry;

[0024] 2) Preparation of PVDF copolymer glue: Stir 152g of deionized water, 19g of vinylidene fluoride-trifluoroethylene copolymer powder, and 19g of PVP evenly, and ultrasonically grind for 30-60min to obtain PVDF copolymer glue;

[0025] 3) Preparation of PVDF copolymer and ceramic mixed slurry: mix 100g of deionized water with 60g of aluminum oxide powder and stir at a speed of 1000r / min for 0.5-1.5h, then add 36g of vinylidene fluoride-three Stir the copolymer powder of vinyl fluoride for 0.5-1h at a rotational speed of 1000r / min, and finally add 4g of polyoxyethylene alkylamide for mixing and grind for 1-2h to obtain a mixed slurry of PVDF copolymer and ceramics;

...

Embodiment 2

[0029] A preparation method for a PVDF copolymer ceramic coating diaphragm, comprising the following steps:

[0030] 1) Preparation of ceramic slurry: 110g of deionized water, 70g of magnesium oxide powder, and 20g of PVA were mixed and stirred, and then ball milled in a ball mill for 1-3 hours to obtain a ceramic slurry;

[0031] 2) Preparation of PVDF copolymer glue: Stir 122.1g of deionized water, 76g of vinylidene fluoride-tetrafluoroethylene copolymer powder, and 1.9g of PVP evenly, then ultrasonically grind for 30-60min to obtain PVDF copolymer glue ;

[0032] 3) Preparation of PVDF copolymer and ceramic mixed slurry: Mix 124g of deionized water and 60g of magnesium oxide powder and stir for 0.5-1.5h at a speed of 1000r / min, then add 6g of vinylidene fluoride-tetrafluoroethylene The copolymer powder was stirred for 0.5-1h under the condition of rotating speed of 1000r / min, and finally 10g of fluoroalkyl ethoxy alcohol ether was added for mixing and then ground for 1-2h ...

Embodiment 3

[0036] A preparation method for a PVDF copolymer ceramic coating diaphragm, comprising the following steps:

[0037] 1) Preparation of ceramic slurry: Mix and stir 60g of deionized water, 120g of calcium oxide powder, and 20g of PMMA, and then ball mill in a ball mill for 1-3 hours to obtain ceramic slurry;

[0038] 2) Preparation of PVDF copolymer glue: Stir 95g of deionized water, 76g of vinylidene fluoride-hexafluoropropylene copolymer powder, and 19g of PVP evenly, and ultrasonically grind for 30-60min to obtain PVDF copolymer glue;

[0039] 3) Preparation of PVDF copolymer and ceramic mixed slurry: mix 96g of deionized water and 80g of calcium oxide powder, stir at a speed of 1000r / min for 0.5-1.5h, then add 20g of vinylidene fluoride-hexafluoropropylene The copolymer powder was stirred for 0.5-1h at a rotational speed of 1000r / min, and finally 4g of fluoroalkyl ethoxy alcohol ether was added for mixing and then ground for 1-2h to obtain a mixed slurry of PVDF copolymer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com