Positive electrode material of lithium-sulfur battery as well as preparation method and application of positive electrode material of lithium-sulfur battery

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, positive electrodes, etc., can solve the problems of unfavorable battery high rate performance, poor ionic conductivity, large volume change, etc. Conductivity, the effect of improving capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Preparation of barium sulfate-coated sulfur composites

[0021] (1) Measure 64.68ml of cyclohexane, 10.92ml of Triton X-100, and 8.4ml of 1-hexanol into a magnetic stirrer and fully mix to form a transparent emulsion;

[0022] (2) Add 2.9ml of uniform elemental sulfur ultrasonic dispersion in water to the transparent emulsion obtained in step (1) (the weight ratio of elemental sulfur to dispersion is 6:10) and fully stir for 5 minutes, then add 2.8ml of solute The sulfuric acid solution with a mass fraction of 35% was fully stirred for 5 minutes, then 10.3ml of barium chloride solution with a solute mass fraction of 20% was added and fully stirred for 5 minutes, filtered, dried, washed, and dried;

[0023] 2. Preparation of cathode materials

[0024] Weigh 0.08 gram of the barium sulfate-coated sulfur composite material obtained above, 0.01 gram of acetylene black, and 0.01 gram of polyvinylidene fluoride and place them in a mortar and grind them evenly, then add 1 ...

Embodiment 2

[0031] Preparation of Barium Sulfate Coated Sulfur Composite

[0032] (1) Measure 65.6ml of isooctane, 9.5g of sodium alkyl alcohol ether carboxylate, and 4ml of n-propanol into a magnetic stirrer and fully mix to form a transparent emulsion;

[0033] (2) Adding 4.6ml of solute mass fraction in the transparent emulsion of gained in step (1) is the uniformly dispersed sodium thiosulfate aqueous solution of 60% and fully stirred for 5 minutes, then adding 3.66ml of solute mass fraction is 20% sulfuric acid The iron solution was fully stirred for 5 minutes, then 11.67ml of barium nitrate solution with a solute mass fraction of 20% was added and fully stirred for 5 minutes, filtered, dried, washed, and dried;

[0034] All the other steps are the same as in Example 1.

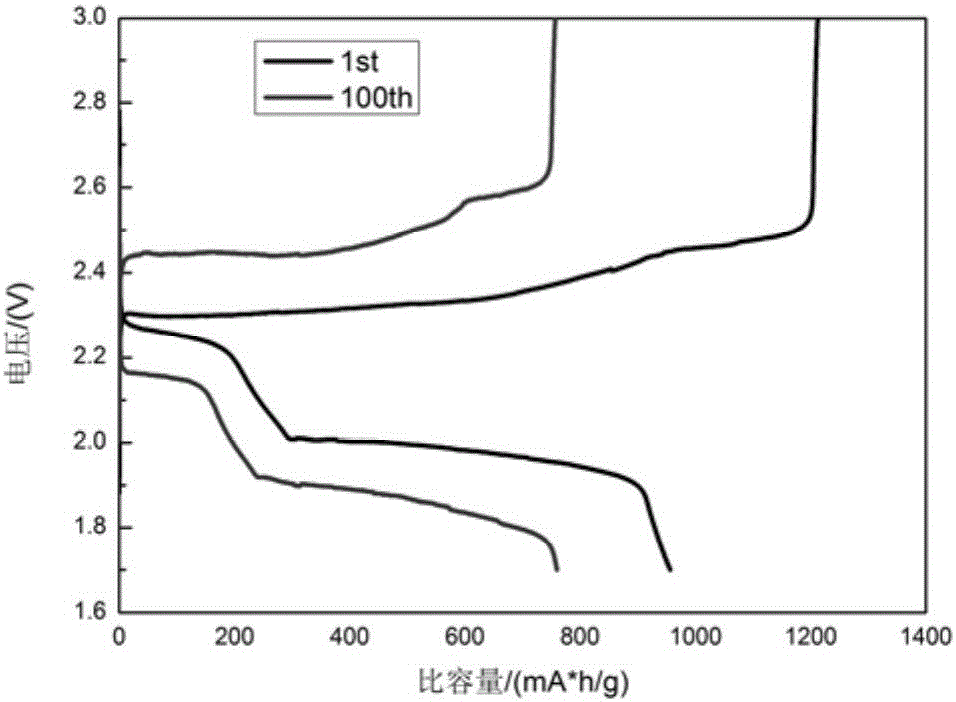

[0035] The electrochemical performance test was carried out on the lithium-sulfur battery prepared in this example, the voltage window was 1.0V-3.0V, the charging and discharging condition was 0.2C, and the Coulomb...

Embodiment 3

[0037] Preparation of Barium Sulfate Coated Sulfur Composite

[0038] (1) Measure 62.32ml of perchlorethylene, 9.07g of sodium secondary alkyl sulfonate, and 3.8ml of 1-octanol and put them into a magnetic stirrer to fully mix to form a transparent emulsion;

[0039] (2) in the transparent emulsion of gained in step (1), adding 2.9ml solute mass fraction is the uniformly dispersed sodium sulfide solution of 60% and fully stirred for 5 minutes, then added the uniform calcium sulfate ultrasonic water dispersion (sulfuric acid) of 2.8ml The weight ratio of calcium to the dispersion is 35:100) and fully stirred for 5 minutes, then added 10.3ml of barium acetate solution with a solute mass fraction of 20% and fully stirred for 5 minutes, filtered, dried, washed and dried;

[0040] All the other steps are the same as in Example 1.

[0041] The electrochemical performance test was carried out on the lithium-sulfur battery prepared in this example, the voltage window was 1.0V-3.0V, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com