A preparing process for instant precipitate-free freeze-dried human fibrinogen

A technology for the preparation of human fibrinogen, applied in the field of biopharmaceuticals, can solve the problems of harsh production process, not too long storage time, protein damage, etc., to optimize the freeze-drying process conditions, shorten the total freeze-drying time, reduce protein the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

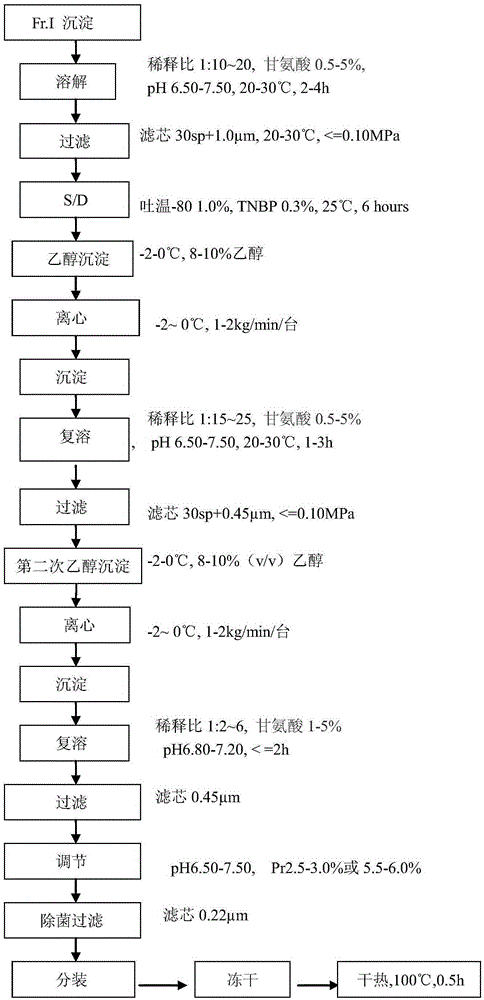

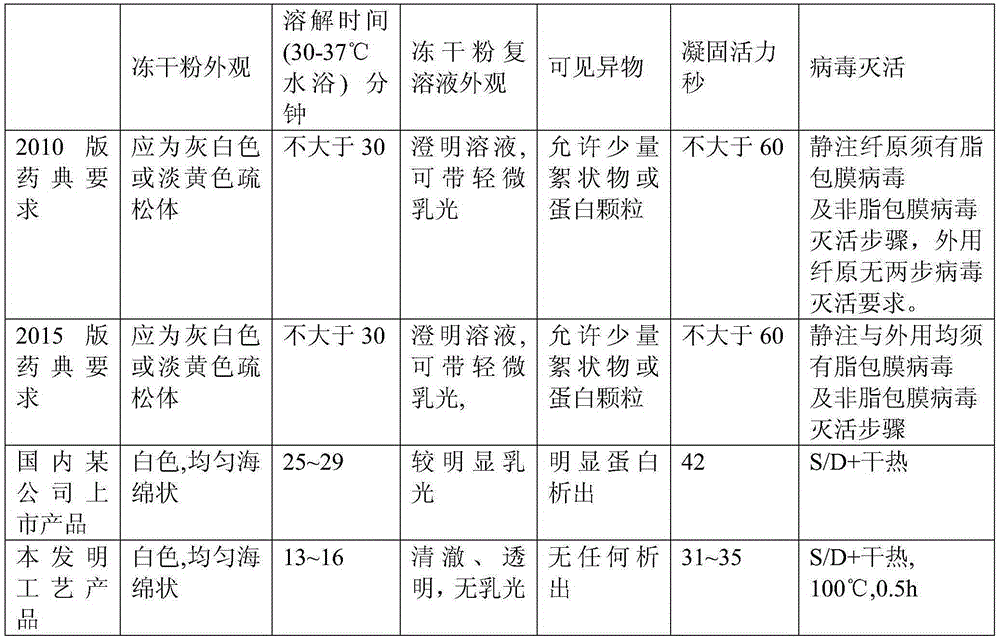

Method used

Image

Examples

Embodiment 1

[0034] In the first step, according to the dilution ratio of 1:20, take 2kg of fresh component I and precipitate it, dilute and chop it immediately, then dissolve it in 40kg buffer 1, and stir it evenly for 3 hours; the formula of buffer 1: sodium citrate·2H 2 O640g, TRIS 108g, lysine hydrochloride 160g, sucrose 600g, glycine 600g, sodium chloride 400g, buffer 1 pH value 6.95, temperature 20°C;

[0035] In the second step, use a 30SP depth filter element in series with a 1.0μm filter element to filter the first suspension; the filtration pressure is controlled at about 0.5bar, and the filter element is washed with buffer 1 of the formula described in the first step, and the filtrate 50.1 is collected kg.

[0036] The third step is to add 2.5 kg of pre-prepared S / D mother liquor to the filtrate to make the concentration of Tween-80 in the solution to 1% and the concentration of TNBP to 0.3%. Stir slowly at 24-26°C and keep it warm for 6 hours ;

[0037] The fourth step is to cool the...

Embodiment 2

[0046] In the first step, take 10kg of fresh component I precipitate and dilute and chop it immediately. According to the dilution ratio of 1:20, put it into 200kg of buffer 1 to dissolve and stir evenly for 1.5 hours; buffer 1 formula: sodium citrate·2H 2 O 3.2kg, TRIS 540g, lysine hydrochloride 800g, sucrose 3kg, glycine 2.0kg, sodium chloride 2.0kg, buffer 1 pH value 6.95, temperature 25℃;

[0047] The second step is to filter the above suspension with a 30SP depth filter element in series with a 1.0 μm (10 inch) filter element; the filtration pressure is controlled at about 0.5 bar, the filter element is washed with about 50 kg of buffer 1 of the above formula, and 251 kg of filtrate is collected.

[0048] The third step is to add 12.5kg of pre-prepared S / D mother liquor to the filtrate to make the concentration of Tween-80 in the solution to 1% and the concentration of TNBP to 0.3%. Stir slowly at 24-26℃ and keep it warm for 6 hours. ;;

[0049] The fourth step is to cool the so...

Embodiment 3

[0058] In the first step, take 10kg of fresh component I and precipitate it, dilute and chop it immediately, according to the dilution ratio of 1:10, and then dissolve it in 100kg of buffer 1, and stir it evenly for 3 hours; the formula of buffer 1: sodium citrate·2H 2 O1.6kg, TRIS 270g, lysine hydrochloride 400g, sucrose 1.5kg, glycine 3.0kg, sodium chloride 1.0kg, buffer 1 pH value is 6.80, temperature 30℃;

[0059] The second step is to filter the above suspension with a 30SP depth filter element in series with a 1.0μm filter element; the filtration pressure is controlled at about 0.5bar, and the filter element is washed with about 50kg of buffer 1 formulated in the first step, and 152kg of filtrate is collected .

[0060] The third step is to add 7.5 kg of pre-prepared S / D mother liquor to the filtrate to make the concentration of Tween-80 in the solution to 1% and the concentration of TNBP to 0.3%. Stir slowly at 24-26°C and keep it warm for 6 hours ;;

[0061] The fourth step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com