Composite material for carrier, method of manufacture and application of tray

A composition and pallet technology, applied in the field of material and pallet processing, can solve the problems of high price, low bearing capacity, poor flexibility in fixing dimensions, etc., and achieve the effects of high product recycling rate, improved recycling rate, and good environmental protection benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

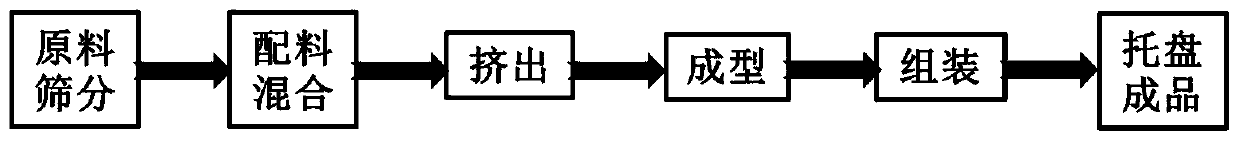

[0066] Prepare the environmental protection tray 1# through the following steps:

[0067] (1) Raw material screening: use 20-mesh and 200-mesh sieves to sieve the raw materials of fly ash, ferrosilicon ash and polyvinyl chloride recycled materials, and package them for use;

[0068] (2) Ingredients mixing: composition according to weight percentage: 25% fly ash, 20% ferrosilicon ash, 35% polyvinyl chloride reclaimed material, 11% light calcium, 2% compound lead salt stabilizer, chlorinated polyvinyl chloride modifier Ethylene 2.5%, foaming agent azodicarbonamide 0.3%, foam regulator methyl acrylate 3%, first lubricant stearic acid 0.8%, second lubricant paraffin 0.4% are weighed, and all the above materials Mix evenly, where the mixing temperature is 110°C, then cool it down to 20°C;

[0069] (3) Extrusion: Use an extrusion molding machine to extrude the mixed raw materials to obtain a composite material for bearing. The temperature of the first barrel is 185°C, the temperatu...

Embodiment 2

[0076] Prepare the environmental protection tray 2# through the following steps:

[0077] (1) Raw material screening: sieve fly ash, ferrosilicon ash and recycled polyvinyl chloride raw materials through 20-mesh and 200-mesh sieves, and package them for use;

[0078] (2) Ingredients mixing: composition according to weight percentage: 40% fly ash, 3% ferrosilicon ash, 29% polyvinyl chloride reclaimed material, 15% light calcium, 3% wood powder (80 mesh), stabilizer composite lead salt 2.3%, modifier 2.1% (chlorinated polyethylene 1.5%, acrylate copolymer 0.6%), foaming agent 0.6% (azodicarbonamide 0.35%, sodium bicarbonate 0.25%), foam regulator acrylic acid Methyl ester 4%, the first lubricant stearic acid 0.8%, the second lubricant 0.2% (paraffin wax 0.1%, PE wax 0.1%) are weighed, all above-mentioned materials are uniformly mixed, and wherein mixing temperature is 130 ℃, again Cool it to 50°C;

[0079] (3) Extrusion: Use an extrusion molding machine to extrude the mixed ra...

Embodiment 3

[0086] Prepare the environmental protection tray 3# through the following steps:

[0087] (1) Raw material screening: sieve fly ash, ferrosilicon ash and recycled polyvinyl chloride raw materials through 20-mesh and 200-mesh sieves, and package them for use;

[0088] (2) Mixing of ingredients: composition according to weight percentage: fly ash 27%, silicon iron ash 6%, polyvinyl chloride recycled material 40%, light calcium 10%, wood flour (120 mesh) 8%, stabilizer dust-free lead Salt multifunctional composite stabilizer 2.5%, modifier 1.2% (chlorinated polyethylene 0.7%, acrylate copolymer 0.5%), foaming agent 0.6% (azodicarbonamide 0.35%, sodium bicarbonate 0.25%) , foam regulator methyl acrylate, 4%, the first lubricant stearic acid 0.4%, the second lubricant PE wax 0.3% are weighed, all the above-mentioned materials are uniformly mixed, wherein the mixing temperature is 120 ℃, and then It is cooled to 30°C;

[0089] (3) Extrusion: Use an extrusion molding machine to ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com