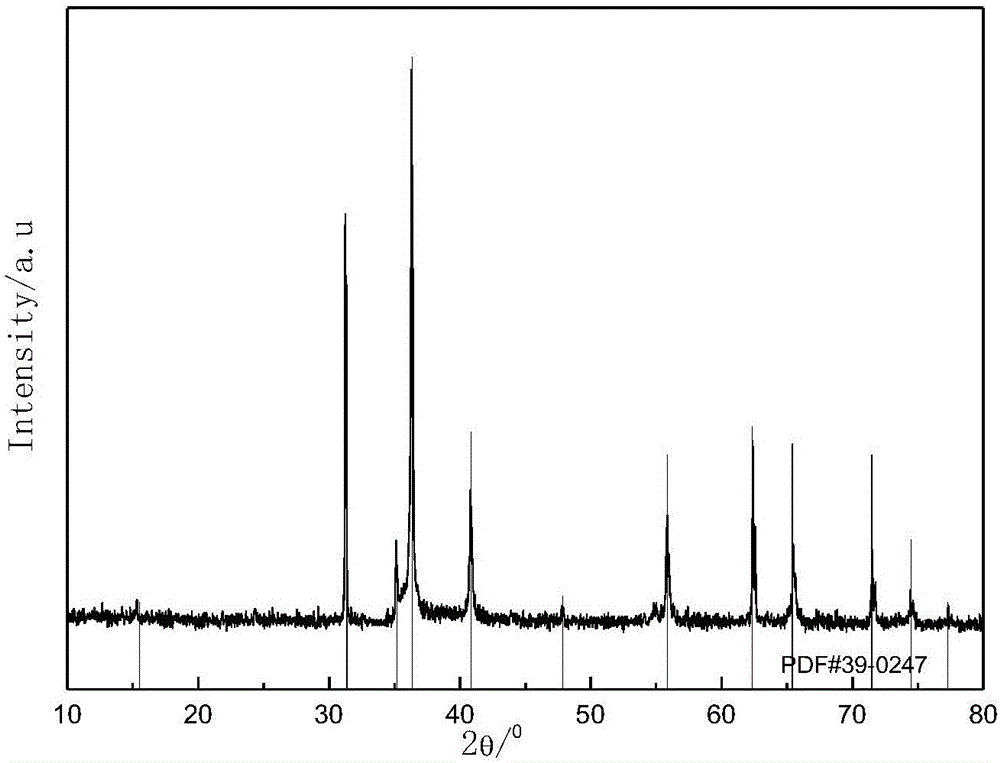

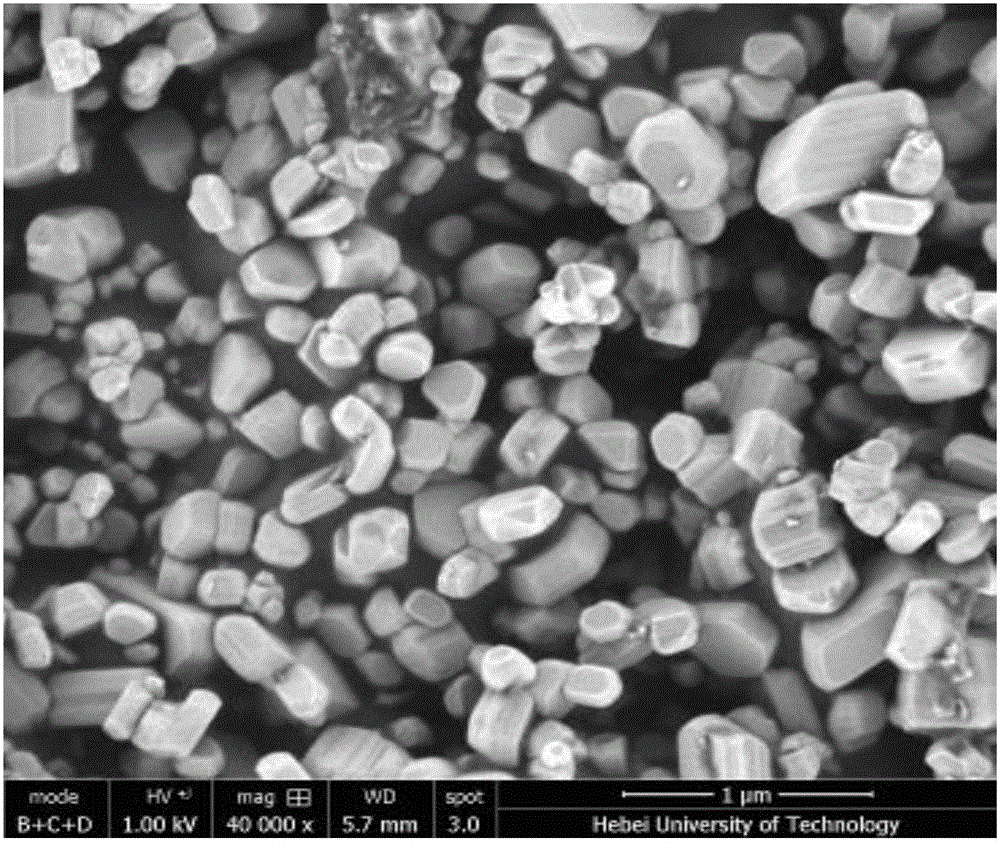

Method for preparing CuCrO2 powder

A technology of powder and copper nitrate, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as unsatisfactory particle size distribution, unsatisfactory crystallization integrity, large CuCrO particle size, etc., to achieve Good crystallization integrity, good water splitting hydrogen production activity, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 4g copper nitrate trihydrate (0.016556mol) and 6.624g chromium nitrate nonahydrate (0.016556mol), put it into a tall beaker, add deionized water to make copper nitrate+chromium nitrate total mass concentration is 10% aqueous solution;

[0024] (2) Glycine is weighed in a ratio of 1.4:1 by a molar ratio with copper nitrate, and citric acid is weighed in a molar ratio of glycine: citric acid is a ratio of 10:1, and the total mass concentration of glycine+citric acid is 20%. Aqueous solution, and join in (1) gained solution, stir 10 minutes;

[0025] (3) taking sodium chloride in a ratio of 0.1:1 by mass ratio with copper nitrate, and being mixed with a solution whose mass concentration is 10%, then adding it to (2) gained solution;

[0026] (4) adjusting the pH value of the solution obtained in (3) to 3 with a mass concentration of 10% ammonia;

[0027] (5) Heat the solution obtained in (4) on a water bath at 85°C, and at the same time perform electric stirrin...

Embodiment 2

[0031] Take the method identical with embodiment 1 to prepare CuCrO 2 , the difference is that the dispersant replaces sodium chloride with potassium chloride, and the addition of potassium chloride is that the mass ratio of potassium chloride and copper nitrate is 0.08:1, and all the other preparation conditions are the same as in Example 1.

Embodiment 3

[0033] Take the method identical with embodiment 1 to prepare CuCrO 2 , the difference is that the molar ratio of the composite combustion agent glycine and citric acid becomes 5:1, and the rest of the preparation conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com