Core-shell spherical molybdenum trioxide/molybdenum disulfide and preparation method thereof

A spherical, core-shell technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of short photocatalytic degradation time, large amount of photocatalyst addition, long photocatalytic degradation time, etc. , to reduce the photocatalytic time, improve the photocatalytic effect, and increase the nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

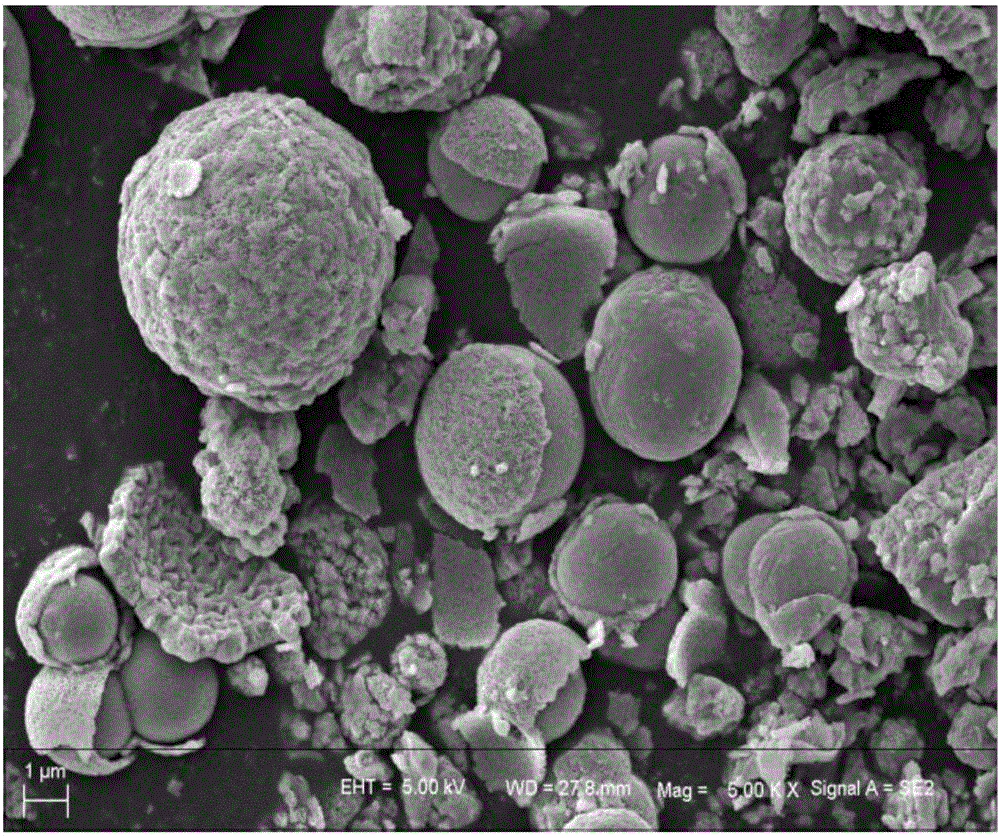

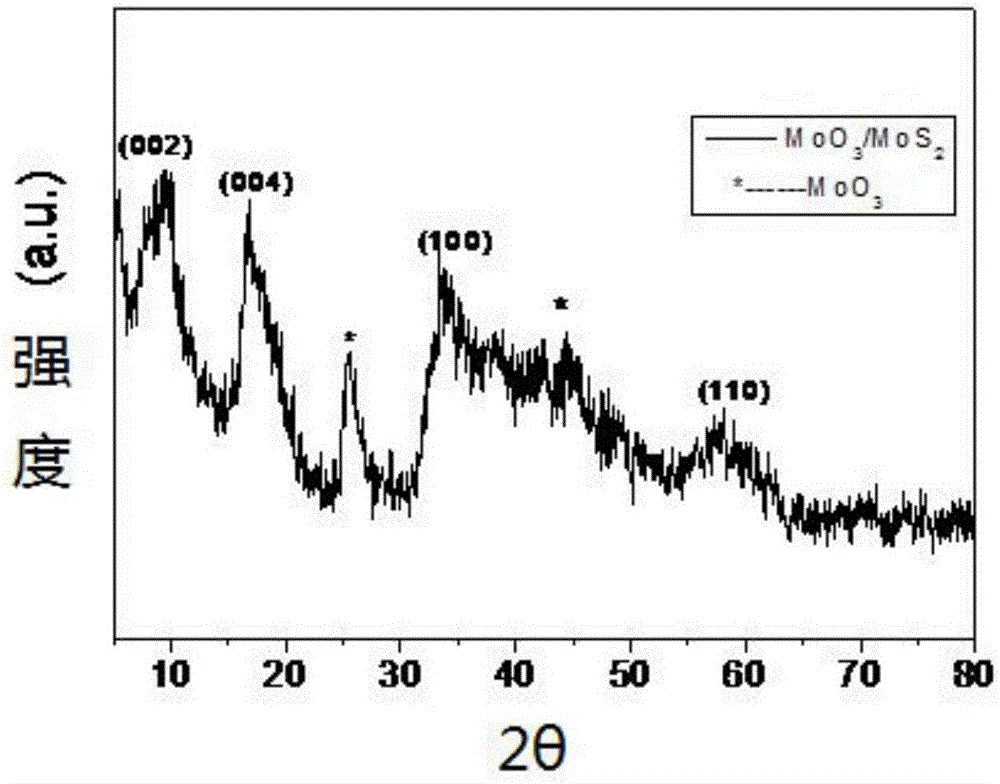

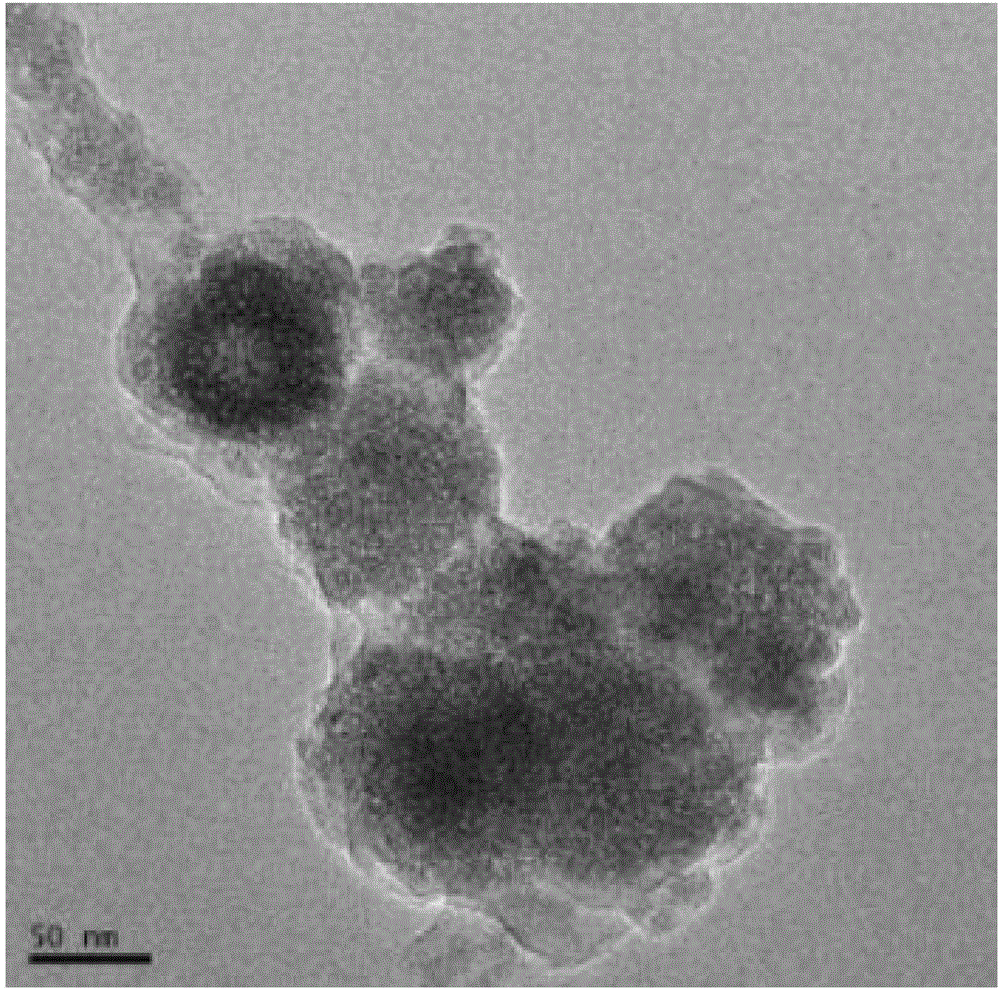

[0046] This embodiment provides a core-shell spherical MoO 3 / MoS 2 and its preparation method. Described preparation method comprises the steps:

[0047] (1) Weigh 0.4319g molybdenum trioxide (MoO 3 ) (3mmol) was added to the deionized water of 20ml, and under magnetic stirring, molybdenum trioxide suspension was obtained, and 0.07287g (0.2mmol) cetyltrimethylammonium bromide (CTAB) was added thereto, and magnetic stirring made It is completely dissolved in the molybdenum trioxide suspension to obtain a molybdenum source solution;

[0048] Weigh 0.8017g of potassium thiocyanate (KSCN) (8mmol) and add it to 20ml of deionized water, under magnetic stirring, to obtain a sulfur source solution;

[0049] (2) Add the sulfur source solution dropwise to the molybdenum source solution at 0.02ml / s, magnetically stir the two to mix evenly, and adjust the pH to 8 to obtain a mixed solution;

[0050] (3) Move the mixed solution to a 50ml autoclave for hydrothermal reaction, and contr...

Embodiment 2

[0058] This embodiment provides a core-shell spherical MoO 3 / MoS 2 and its preparation method. Described preparation method comprises the steps:

[0059] (1) The ammonium molybdate that takes 2mmol is added to the deionized water of 20ml, under magnetic stirring, obtains ammonium molybdate aqueous solution, and the cetyltrimethylammonium bromide (CTAB) that adds 0.2mmol wherein, magnetic force Stir to make it completely dissolved in the ammonium molybdate aqueous solution to obtain a molybdenum source solution;

[0060] Weigh 6mmol of thiourea and add it to 20ml of deionized water, under magnetic stirring, to obtain a sulfur source solution;

[0061] (2) Add the sulfur source solution dropwise to the molybdenum source solution at 0.05ml / s, magnetically stir the two to mix evenly, and adjust the pH to 9 to obtain a mixed solution;

[0062] (3) Move the mixed solution to a 50ml autoclave for hydrothermal reaction, and control the temperature of the hydrothermal reaction to ...

Embodiment 3

[0070] This embodiment provides a core-shell spherical MoO 3 / MoS 2 and its preparation method. Described preparation method comprises the steps:

[0071] (1) The ammonium molybdate that takes 4mmol is added to the deionized water of 20ml, under magnetic stirring, obtains ammonium molybdate aqueous solution, and the cetyltrimethylammonium bromide (CTAB) of wherein adding 0.8mmol, magnetic force Stir to make it completely dissolved in the ammonium molybdate aqueous solution to obtain a molybdenum source solution;

[0072] Weigh 2mmol of sodium thiosulfate and add it to 20ml of deionized water, and stir magnetically to prepare a sulfur source solution;

[0073] (2) Add the sulfur source solution dropwise to the molybdenum source solution at 0.008ml / s, magnetically stir the two to mix evenly, and adjust the pH to 12 to obtain a mixed solution;

[0074] (3) Move the mixed solution to a 50ml autoclave for hydrothermal reaction, and control the temperature of the hydrothermal re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com