Concrete moisture evaporation inhibitor and preparation method and application thereof

An evaporation inhibitor and concrete technology, applied in the field of concrete, can solve the problems of laborious, troublesome construction, difficult to remove, etc., and achieve the effects of good anti-cracking effect, inhibiting water evaporation, and reducing plastic cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

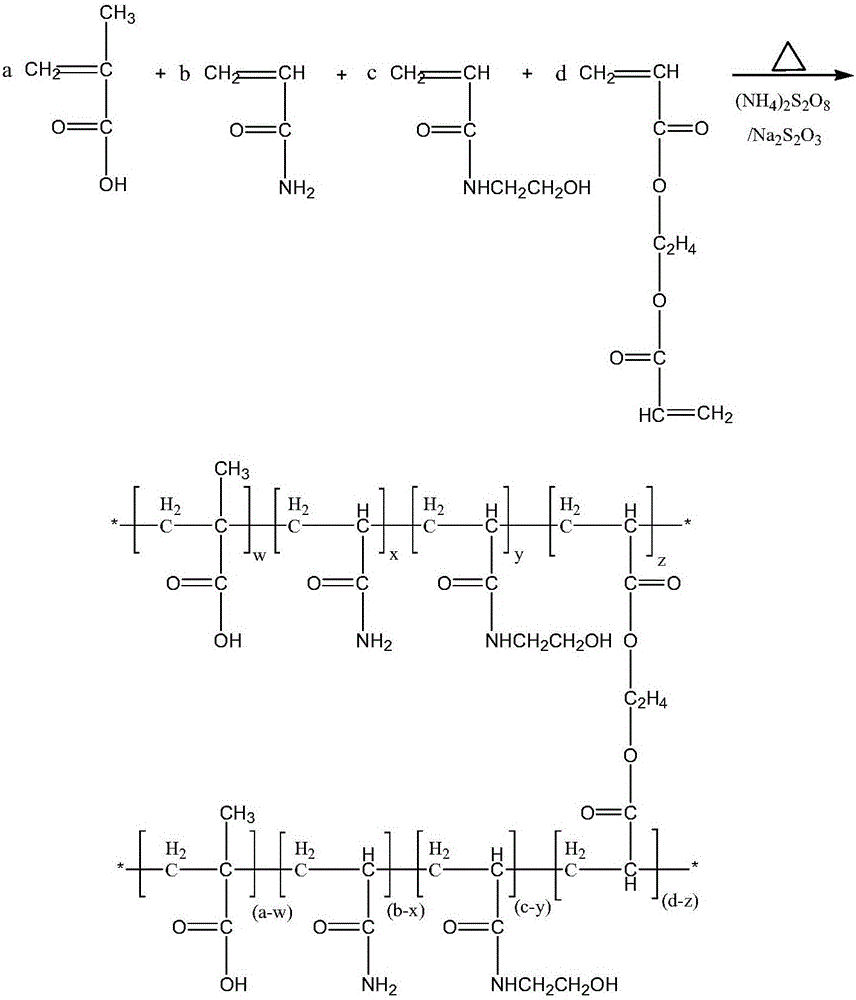

[0036] A concrete water evaporation inhibitor, the monomers involved are methacrylic acid, acrylamide, N-hydroxyethylacrylamide and ethylene glycol diacrylate, and its material ratio is 1:1.5:0.2:0.01, its The preparation method specifically comprises the following steps:

[0037] (1) Add 43.0g of methacrylic acid, 53.3g of acrylamide, 11.5g of N-hydroxyethylacrylamide, 0.85g of ethylene glycol diacrylate, and 653.0g of deionized water into a 1L four-necked flask, and stir evenly. After all the monomers are dissolved, add 5g of isopropanol and 2g of ammonium persulfate, and stir evenly;

[0038] (2) Adding 80 g of sodium sulfite solution with a mass fraction of 0.1% dropwise in the solution obtained in step (1), controlling the water bath at 35° C., the dropwise addition time is 3 h, and the dropwise addition is completed and incubated for 1 h; after the reaction is completed, add 30 wt % sodium hydroxide The pH of the aqueous solution is adjusted to 7 to obtain the concrete ...

Embodiment 2

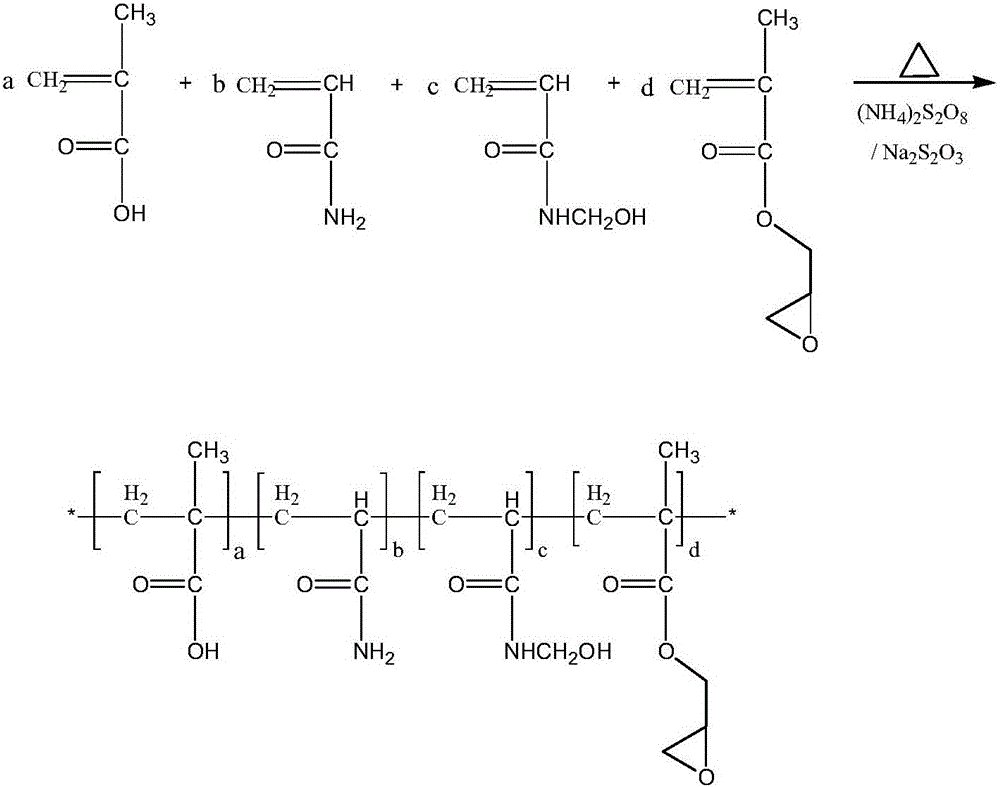

[0044] A concrete moisture evaporation inhibitor, the monomers involved are methacrylic acid, acrylamide, N-methylolacrylamide and glycidyl methacrylate, and its material ratio is 1:1.5:0.2:0.01, its The preparation method comprises the following steps:

[0045] (1) Add 43.0g of methacrylic acid, 53.3g of acrylamide, 10.1g of N-methylolacrylamide, 0.7g of glycidyl methacrylate, and 720g of deionized water into a 1L four-neck flask, stir well, and wait until After the body is completely dissolved, add 3 g of mercaptoethanol and 1.2 g of ammonium persulfate, and stir evenly;

[0046] (2) in step (1) gained solution, dripping mass fraction is 0.2% sodium thiosulfate solution 60g, controls water bath 35 ℃, and the time of dropping is 3h, and dropwise completes insulation 1h; Reaction completes, adds 30wt% The aqueous sodium hydroxide solution adjusts the pH to 7 to obtain the concrete moisture evaporation inhibitor solution.

[0047] The obtained concrete moisture evaporation in...

Embodiment 3

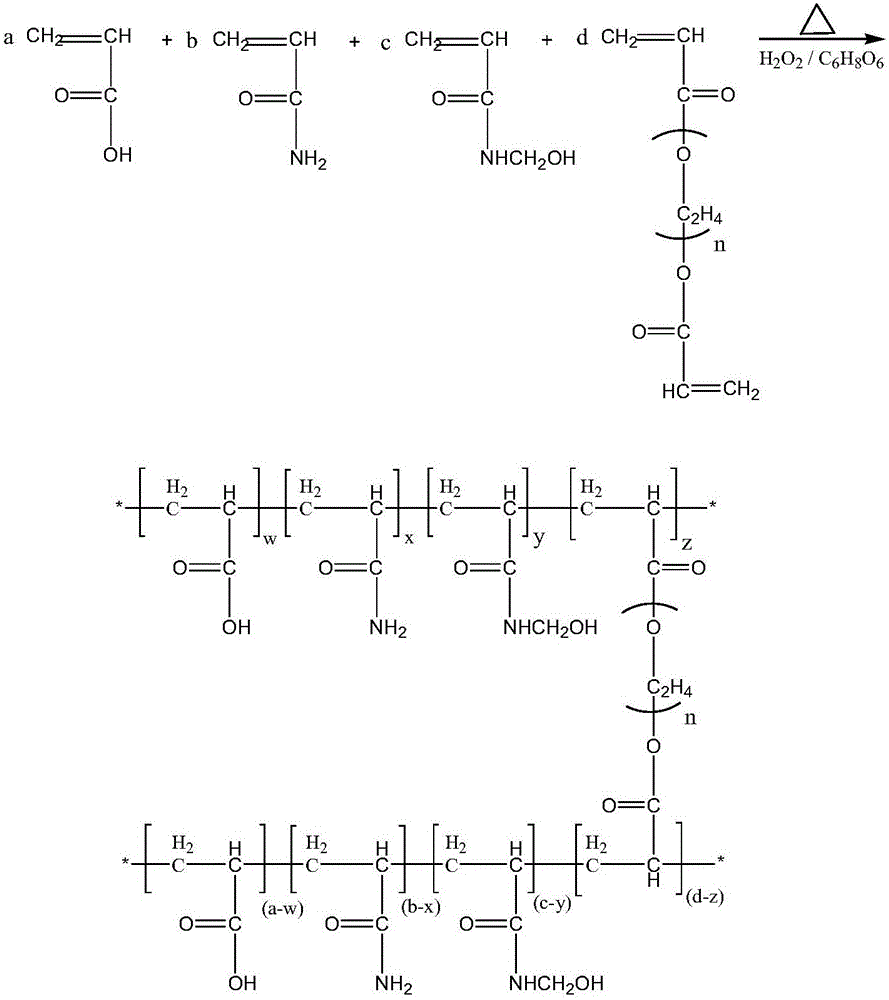

[0052] A concrete moisture evaporation inhibitor, the monomers involved are acrylic acid, acrylamide, N-hydroxyethylacrylamide and polyethylene glycol diacrylate (average molecular weight 400), and the molar ratio of the substances is 1:1:0.1 :0.05, its preparation method comprises the following steps:

[0053] (1) Add 36g of acrylic acid, 35.5g of acrylamide, 5.2g of N-methylolacrylamide, 10g of polyethylene glycol diacrylate (average molecular weight 400), and 692g of deionized water into a 1L four-necked flask, and stir evenly. After all the monomers are dissolved, add 2 g of thioglycolic acid and 1.5 g of hydrogen peroxide, and stir evenly;

[0054] (2) Adding 40 g of L-ascorbic acid solution with a mass fraction of 0.2% dropwise in the solution obtained in step (1), controlling the water bath to 40° C., the time for dropping is 4 hours, and the dropwise addition is completed and kept for 1 hour; after the reaction is completed, add 30 wt % of hydrogen The pH of the sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com