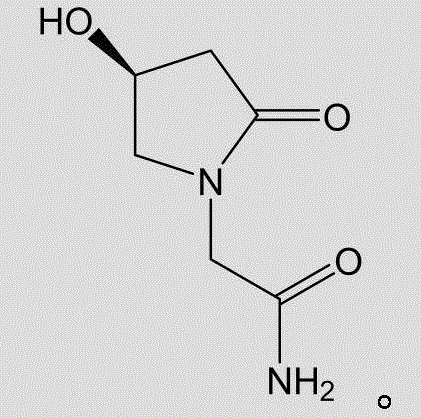

Method for preparing levorotatory oxiracetam oral dispersible film preparation

A technology of dispersing film and oral cavity, which is applied in the field of preparing levo-oxiracetam oral dispersible film, can solve the problems of harm to patients, low drug loading, large solid particle agglomeration, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

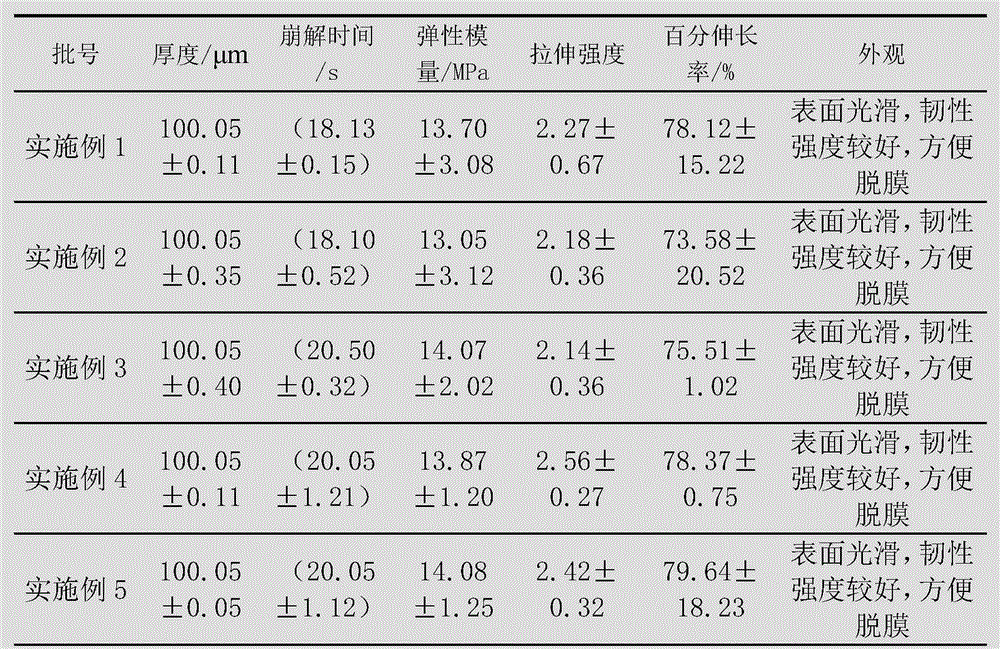

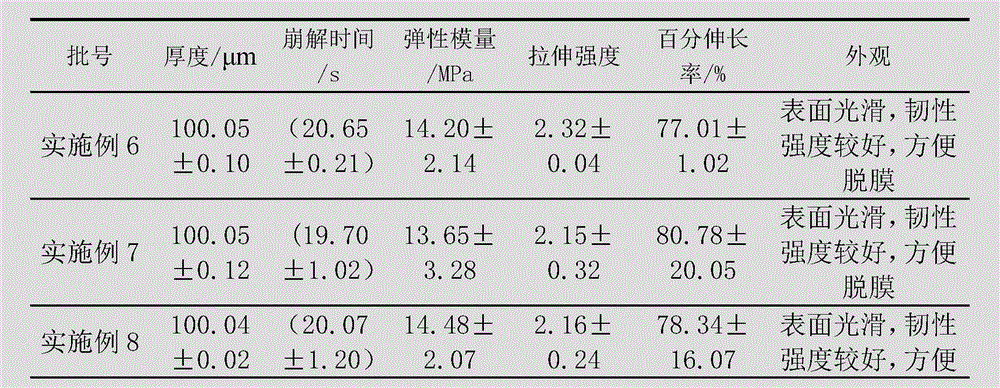

Embodiment 1

[0078] The preparation of levoxiracetam orodispersible film, adopts following steps:

[0079] 1) Dissolve 60g of film-forming material (a combination of acrylate and hydroxypropylmethylcellulose, where the dosage of hydroxypropylmethylcellulose is 30g) with 80mL of absolute ethanol, and remove the air bubbles to obtain a uniform viscous liquid;

[0080] 2) Disperse 15g of glycerin, 20g of microcrystalline cellulose, 4g of malic acid and 2g of sorbitol with 50mL of absolute ethanol to form a dispersion;

[0081] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 5g of levoxiracetam to disperse evenly, and then let it stand to remove air bubbles;

[0082] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 50cm / min, then dry at 65-68°C, and peel off.

Embodiment 2

[0084] The preparation of levoxiracetam orodispersible film, adopts following steps:

[0085] 1) Dissolve 40g of film-forming material (a combination of acrylate and hydroxypropylmethylcellulose, wherein the dosage of hydroxypropylmethylcellulose is 10g) with 50mL of absolute ethanol, and remove the air bubbles to obtain a uniform viscous liquid;

[0086] 2) Disperse 20g of propylene glycol, 20g of low-substituted hydroxypropyl cellulose, 2g of citric acid and 1g of xylitol with 60mL of absolute ethanol to form a dispersion;

[0087] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 18g of levoxiracetam to disperse evenly, then let it stand to remove air bubbles;

[0088] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 80cm / min, then dry at 70-72°C, and peel off.

Embodiment 3

[0090] The preparation of levoxiracetam orodispersible film, adopts following steps:

[0091] 1) Dissolve 50g of film-forming material (a combination of acrylate and hydroxypropyl methylcellulose, where the dosage of hydroxypropylmethylcellulose is 20g) with 50mL of absolute ethanol, and remove air bubbles to obtain a uniform viscous liquid;

[0092] 2) Disperse 15g of triethyl citrate, 20g of microcrystalline cellulose, 3g of ascorbic acid and 1g of sorbitol with 40mL of absolute ethanol to form a dispersion;

[0093] 3) Add the dispersion of step 2) to the viscous liquid of step 1), and add 15g of levoxiracetam to disperse evenly, then let it stand to remove air bubbles;

[0094] 4) Coat the viscous liquid after removing air bubbles with a drug film coating dryer at a coating speed of 70cm / min, then dry at 80-85°C, and peel off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com