High-strength fly ash based fiber foaming self-thermal-insulation material

A fly ash, high-strength technology is applied in the field of high-strength fly ash-based fiber foamed self-insulation materials, which can solve the problems of performance to be improved, high price, low added value of finished products, etc. Good self-insulation effect and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-strength fly ash-based fiber foaming self-insulation material, according to the weight ratio of raw materials: base material: fly ash 60%; plasticizer: organic polymer 0.05%; high-strength fiber 1.0%, gelling agent: 15% of cement; 20% of quicklime; 6% of gypsum. The plasticizer used is a high-molecular organic polymer, which can increase the cohesion between material particles, reduce the amount of cement, and enhance the bending resistance of the material And compressive strength, the used organic polymer can be waterborne epoxy resin, consumption is 0.05%; High-strength fiber can use polybenimidazole fiber, high-strength fiber can strengthen the flexural performance of material, increase the strength of material.

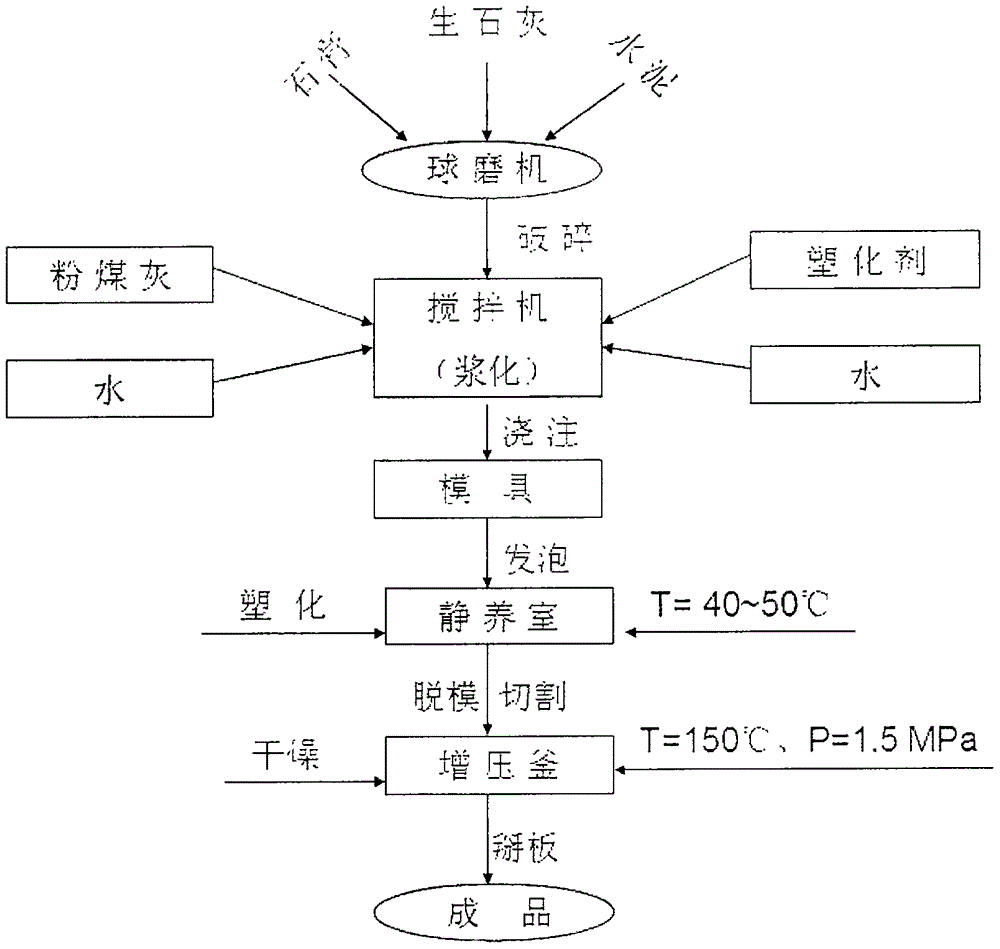

[0028] according to figure 1 The process flow chart for manufacturing the fly ash-based polymer foamed thermal insulation material shown, the high-strength fly ash-based fiber foamed self-insulated material, its preparation process includes the follo...

Embodiment 2

[0038] A high-strength fly ash-based fiber foaming self-insulation material, according to the weight ratio of raw materials: base material: fly ash 50%; plasticizer: phthalate diester 0.5%; glass fiber 0.5%; gelling Agent: cement 10%; quicklime 15%; gypsum 4%.

[0039] according to figure 1 The process flow chart for manufacturing the fly ash-based polymer foamed thermal insulation material shown, the high-strength fly ash-based fiber foamed self-insulated material, its preparation process includes the following steps:

[0040] (1) Raw material crushing: the raw material cement, quicklime, gypsum ball milled into 100 orders;

[0041](2) Slurry: Add the crushed raw materials into the mixer according to the weight ratio, and add fly ash, water and plasticizer, then fully stir, add water and stir to obtain a uniform slurry;

[0042] (3) Pouring: pour the slurry into the mold to foam, and the general mold is a cuboid;

[0043] (4) Plasticization: Transfer the mold containing th...

Embodiment 3

[0049] A high-strength fly ash-based fiber foaming self-insulation material, according to the weight ratio of raw materials: base material: fly ash 80%; plasticizer: bisphenol A epoxy resin 0.2%; polyester fiber 1.2%; Gelling agent: cement 8%; quicklime 12%; gypsum 8%, the bisphenol A type epoxy resin: epoxy group and hydroxyl endow the resin with reactivity, so that the cured resin has strong cohesion and adhesion ; The ether bond and hydroxyl group contained in the molecule are polar groups, which help to improve the wettability and adhesion; the ether bond and C-C bond contained in the molecule make the macromolecule flexible; the benzene ring contained in it endows the polymer with Heat resistance and rigidity; the isopropyl group reduces the intermolecular force, endows the resin with a certain degree of toughness, and increases the bending resistance of the material; due to the high bond energy of the -C-O- bond contained in the molecule, the alkali resistance is improved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com