Method for synthesizing copper indium diselenide quantum dot

A synthesis method and technology of quantum dots, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as being unsuitable for industrial production, unfavorable for industrial production, harsh reaction conditions, etc. The effect of stable structure, short process cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh 0.1111mg (1.0mmol) of selenium dioxide and put it into a round bottom flask, add 3ml of oleylamine to it, put it in a constant temperature oil bath at 100°C for 6 minutes, and after cooling to room temperature, add 19.0mg (0.1mmol) of cuprous iodide to it , 58.4mg (0.2mmol) of indium acetate, the reaction vessel was placed in a 210°C constant temperature oil bath for 20 minutes, and then cooled to room temperature; the solution after the reaction was centrifuged, and the supernatant was discarded and washed with n-hexane. Centrifuge, discard the precipitate again, add ethanol to the supernatant to wash and centrifuge, repeat the washing and centrifugation several times until the supernatant after centrifugation is colorless and transparent, and take the final precipitate as the final product.

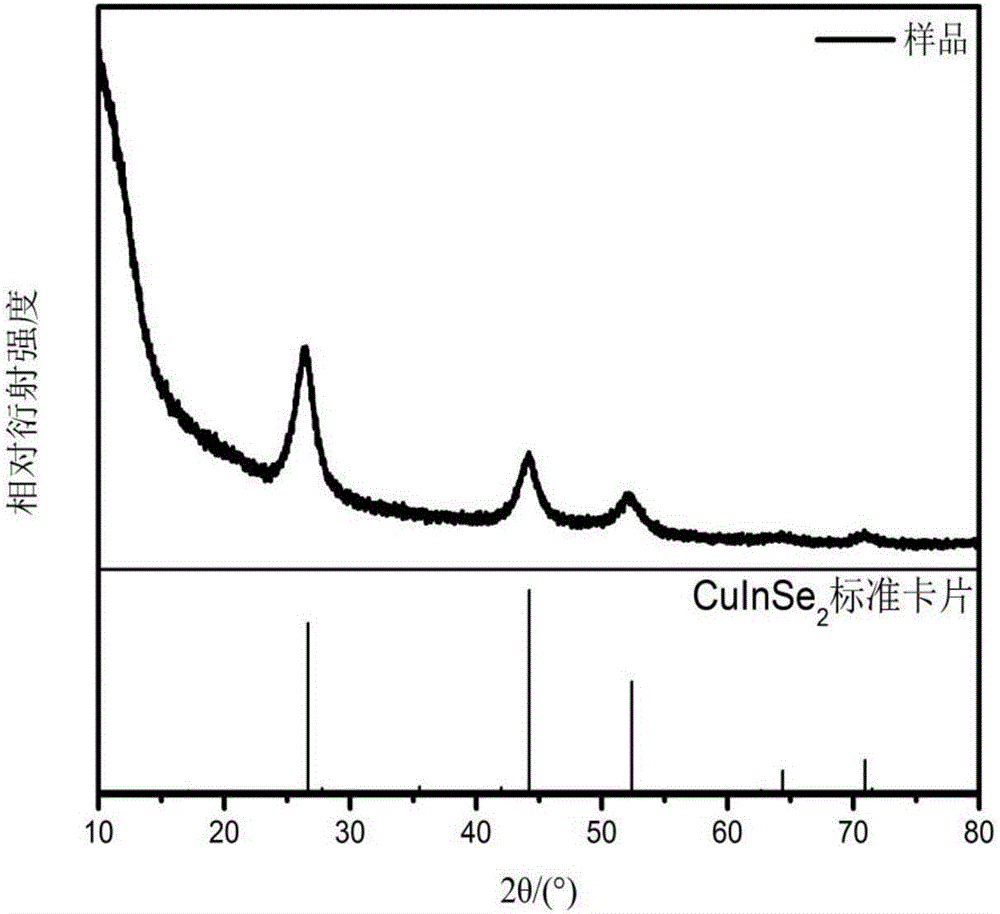

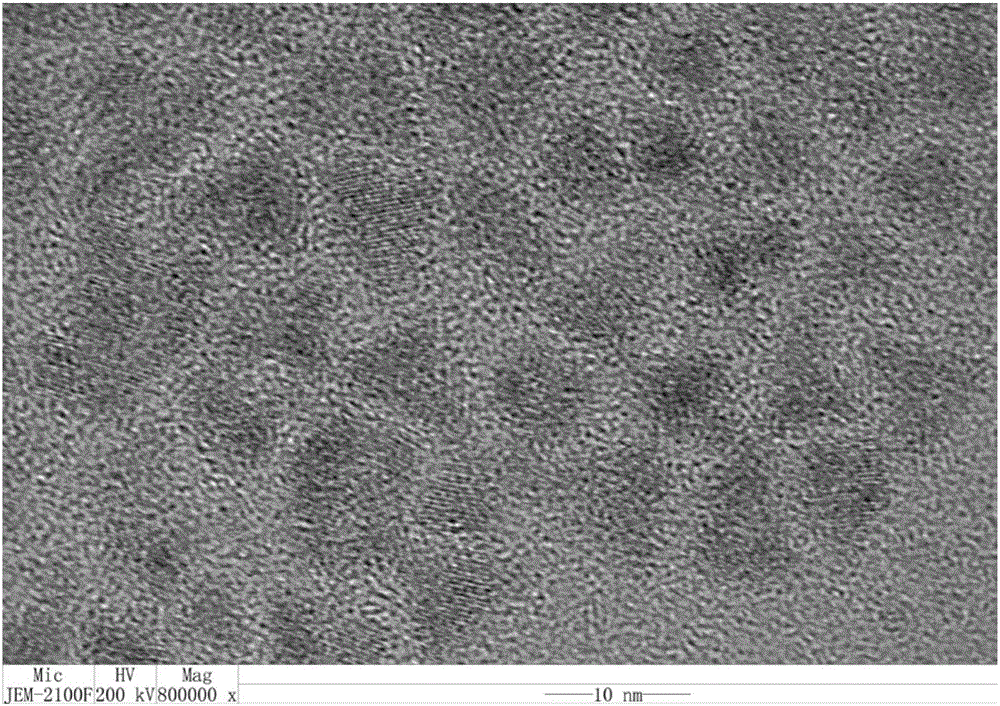

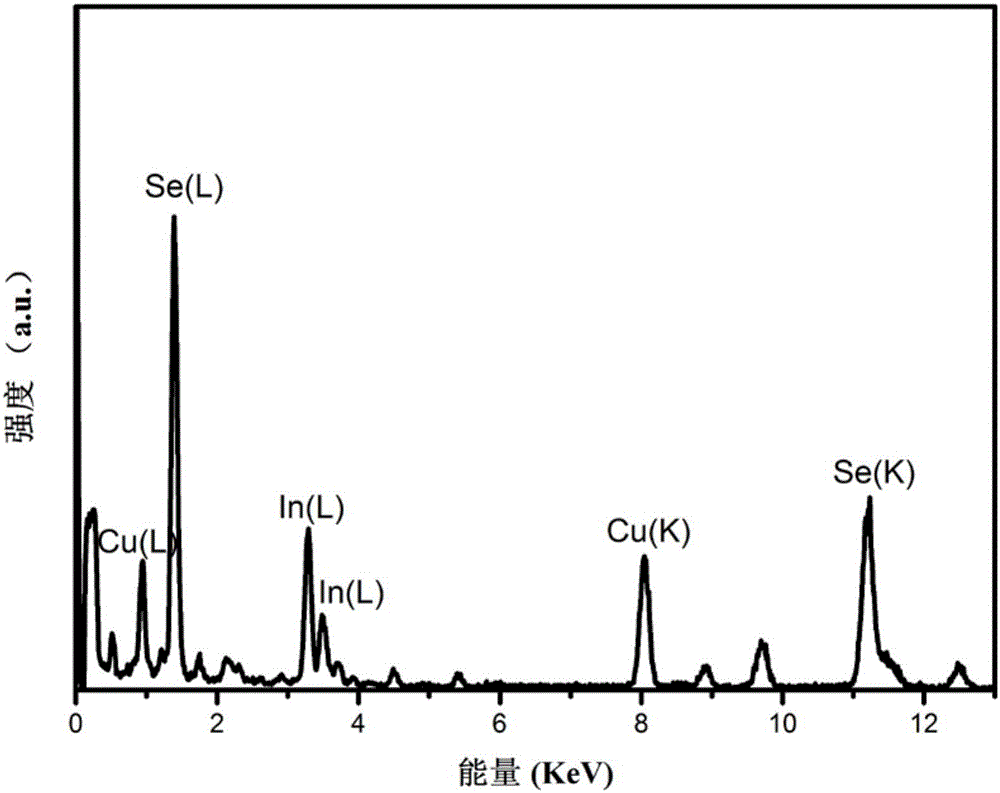

[0047] Product composition, structure and morphology characterization:

[0048] The final product is dissolved in dichloromethane, and after the dichloromethane volatilizes...

Embodiment 2

[0063] Weigh 0.1111mg (1.0mmol) of selenium dioxide and put it into a round bottom flask, add 3ml of oleylamine to it, put it in a constant temperature oil bath at 100°C for 6 minutes, and after cooling to room temperature, add 26.2mg (0.1mmol) of copper acetylacetonate, 82.4mg (0.2mmol) of indium acetylacetonate, the reaction vessel was placed in a 210°C constant temperature oil bath for 20 minutes, and then cooled to room temperature; the solution after the reaction was centrifuged, and the supernatant was discarded and washed with n-hexane. Centrifuge, discard the precipitate again, add ethanol to the supernatant to wash and centrifuge, repeat the washing and centrifugation several times until the supernatant after centrifugation is colorless and transparent, and take the final precipitate as the final product.

[0064] Product composition, structure and morphology characterization:

[0065] The final product is dissolved in dichloromethane, and after the dichloromethane vo...

Embodiment 3

[0073] Weigh 0.1111mg (1.0mmol) of selenium dioxide and put it into a round bottom flask, add 3ml of oleylamine to it, put it in a constant temperature oil bath at 100°C for 6 minutes, and after cooling to room temperature, add 19.0mg (0.1mmol) of cuprous iodide to it , 82.4mg (0.2mmol) indium acetylacetonate, put the reaction vessel in a constant temperature oil bath at 210°C for 20 minutes, then cool to room temperature; centrifuge the reacted solution, discard the precipitate and wash the supernatant with n-hexane And centrifugal separation, after discarding the precipitate again, add ethanol to the supernatant to wash and centrifuge, repeat the washing and centrifugation several times until the supernatant after centrifugation is colorless and transparent, take the final precipitate as the final product obtained .

[0074] The final product is dissolved in dichloromethane, and after the dichloromethane volatilizes, the product is subjected to XRD measurement, and the X-ray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com