A comprehensive treatment method for arsenic-containing materials

A comprehensive processing and material technology, applied in the field of metallurgy, to achieve the effect of high resource utilization, low arsenic content, and reduced arsenic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

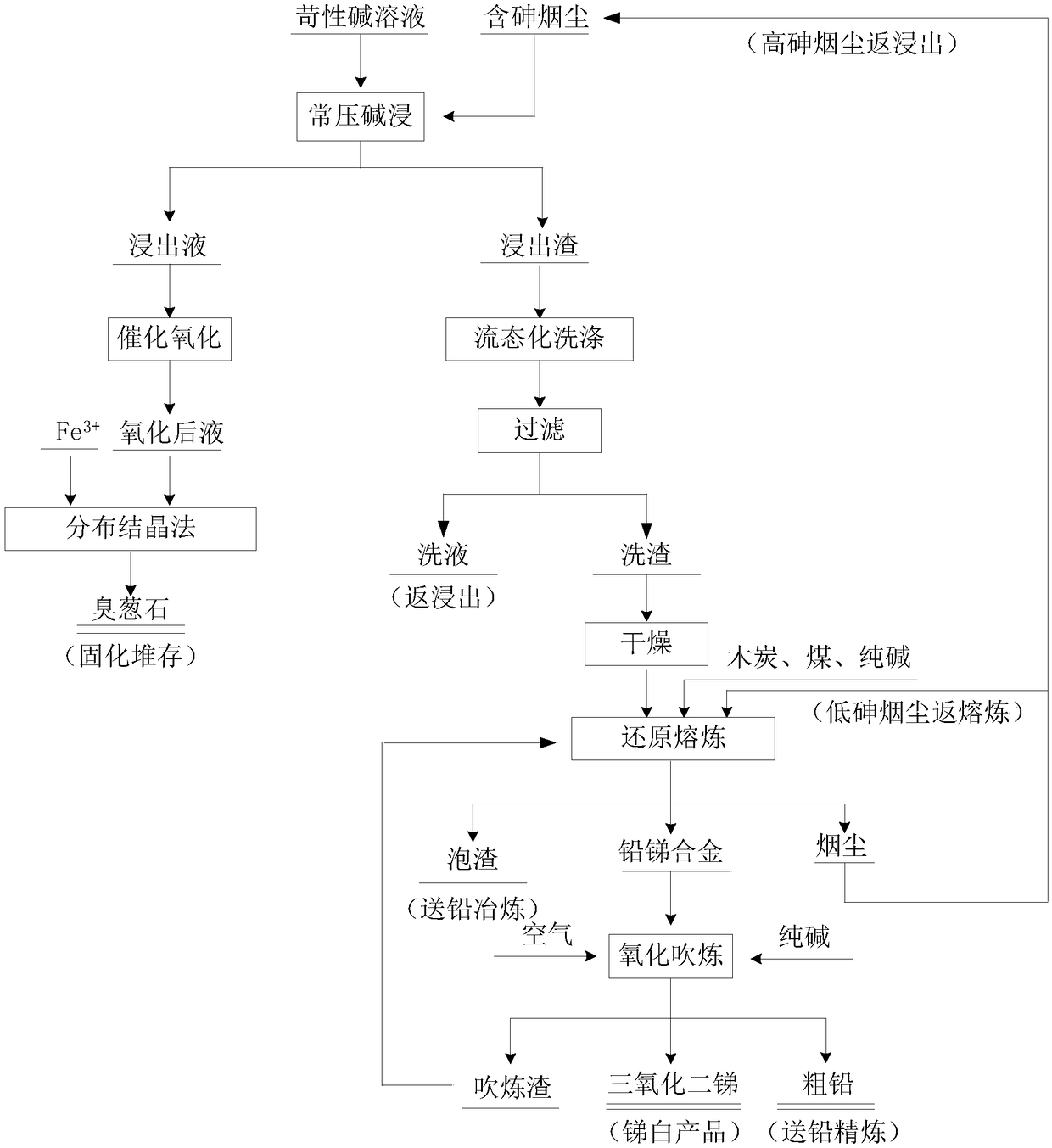

Image

Examples

Embodiment 1

[0053] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, it includes the following main components in terms of mass percentage: Pb 5.26%, As 39.65%, Sn 0.5%, Sb 29.36%, Zn 0.12%, Se 0.04%.

[0054] Weigh a certain mass of the high arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio of 10:1 (ml:g), the stirring speed is 700r / min, the NaOH concentration is 1mol / L, the leaching temperature is 80°C, and the leaching time is 2h. conditions for leaching experiments. After the leaching, the slurry was removed and separated by filtration; the arsenic leaching rate was measured to be 72.36%. The concentration of each element in the leach solution: Pb 86.00ppm, Se 1.80ppm, Zn 20ppm, Sb 1.36g / L, As 28.69g / L.

[0055] The resulting leaching solution was catalyzed to oxidize As 3+ Oxidized to As 5+ , the control conditions are as follows: the oxygen flow rate is 5L / min, the molar ratio of As to Mn is controlled ...

Embodiment 2

[0061] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, it includes the following main components in terms of mass percentage: Pb 10.39%, As 34.59%, Sn 1.45%, Sb 20.54%, Zn 0.11%, Se 0.24%.

[0062] Weigh a certain mass of the high arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio of 10:1 (ml:g), the stirring speed is 700r / min, the NaOH concentration is 3mol / L, the leaching temperature is 50°C, and the leaching time is 4h. conditions for leaching experiments. After the leaching, the slurry was removed and separated by filtration; the arsenic leaching rate was measured to be 52.06%. The element concentrations in the leach solution were Pb 87ppm, Se 0.52ppm, Zn 71ppm, Sb 1.24g / L, As 18.01g / L.

[0063] The leaching solution adopts the method of catalytic oxidation to decompose As 3+ Oxidized to As 5+ , the control conditions are as follows: the oxygen flow rate is 10L / min, the molar ratio of As to M...

Embodiment 3

[0069] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, it includes the following main components in terms of mass percentage: Pb 19.57%, As 24.26%, Sn 1.47%, Sb 30.45%, Zn 0.16%, Se 0.21%.

[0070]Weigh a certain mass of the high arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio 5:1 (ml:g), stirring speed 1000r / min, NaOH concentration 1mol / L, leaching temperature 30 ℃, leaching time 2h conditions for leaching experiments. After the leaching, the slurry was removed and separated by filtration; the arsenic leaching rate was measured to be 42.26%. The concentration of each element in the leach solution was Pb 124ppm, Se0.67ppm, Zn 107ppm, Sb 2.02g / L, As 10.25g / L.

[0071] The resulting leaching solution was catalyzed to oxidize As 3+ Oxidized to As 5+ , the control conditions are as follows: the oxygen flow rate is 1L / min, the molar ratio of As to Mn is controlled at 20:1, and the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com