Method of carrying out chemical nickel-plating phosphorus alloy treatment on ZK61M magnesium alloy complex part

A technology of electroless nickel-phosphorus plating and ZK61M, which is applied in the field of spacecraft engineering, can solve problems such as the inability to meet the production and plating requirements of ZK61M magnesium alloy complex parts of spacecraft, and improve the activity and plating speed of the plating solution, with good effect and easy starting. The effect of plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

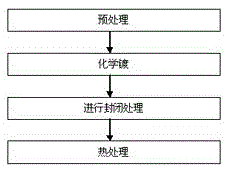

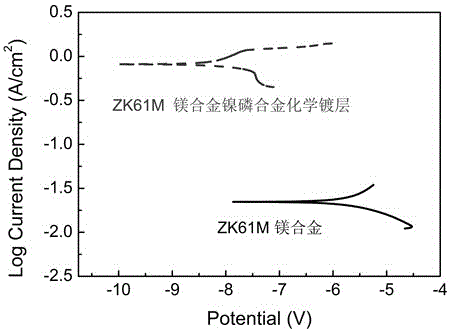

[0024] Combine below figure 1 Process flow in and figure 2 For the complex magnesium alloy parts in the present invention, the electroless nickel-phosphorus alloy plating method for the ZK61M magnesium alloy complex parts is described.

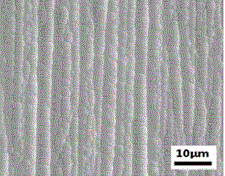

[0025] Specimen is figure 2 The ZK61M magnesium alloy complex after machining is shown.

[0026] 1) Dip the magnesium alloy complex parts into the alkaline cleaning tank for alkaline cleaning: the alkaline cleaning solution is sodium carbonate 20 ~ 40 g / L, sodium hydroxide 10 ~ 30 g / L, OP-10 0.1 ~ 3 mL / L, solution temperature The temperature is 70 ~ 90 ℃, and the processing time is 5 ~ 10 minutes.

[0027] 2) Immerse the magnesium alloy complex parts in the washing tank for 30-60 s to remove the residual lye on the parts.

[0028] 3) The magnesium alloy complex parts are immersed in the first step activation tank for the first step activation: the activation solution is sodium fluoride 5 ~ 30g / L, the solution temperature is 30 ~ 50 ℃, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com