Composite electrode and preparation method and application thereof

A composite electrode and hybrid technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as loss of active materials, and achieve the effects of improving electrical conductivity, achieving uniform dispersion, and good electron transmission capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

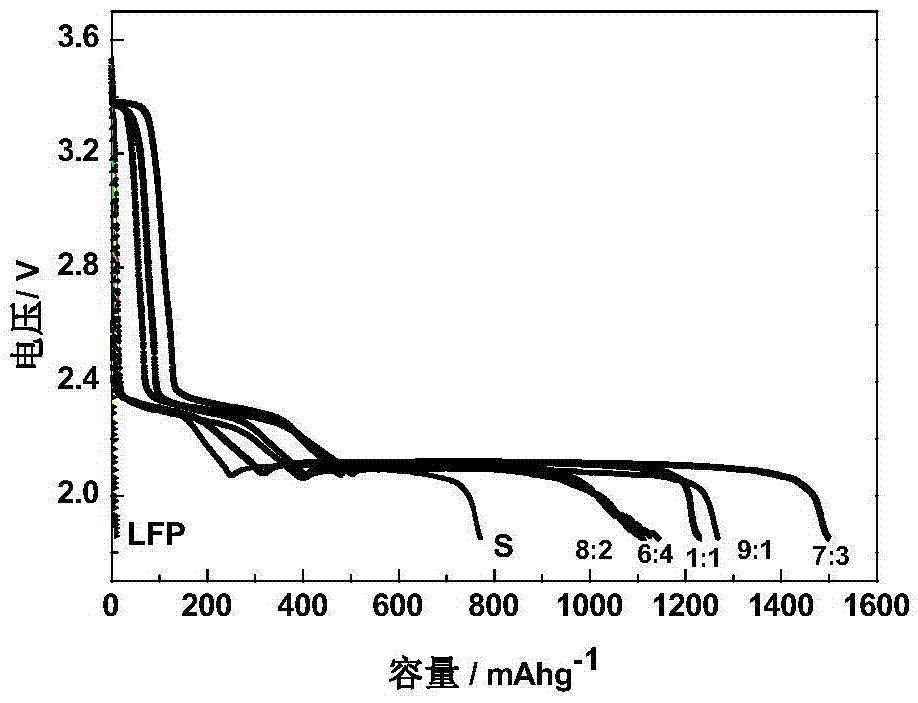

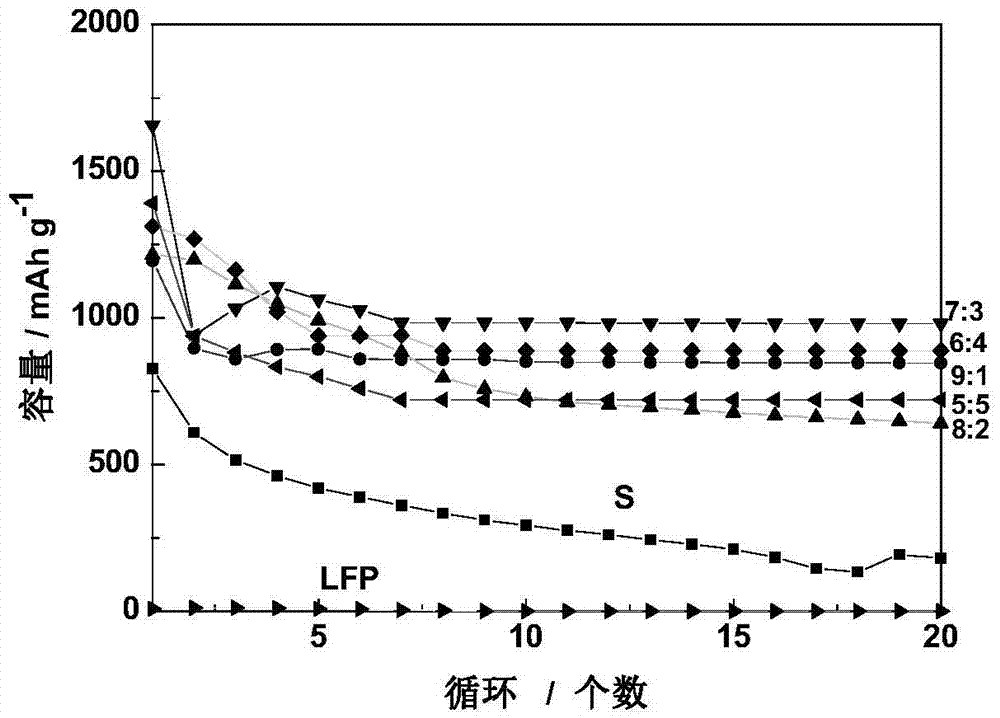

[0032] Lithium iron phosphate and elemental sulfur were mixed at a ratio of 8:2 and ball milled at 300r / min for 3 hours to obtain product A. Take 0.1g of A, add 24.7mg of commercial KB carbon powder, mix evenly, and disperse in 1.3g of N-methylpyrrolidone ( NMP), after uniform dispersion, ultrasonic 20min, stirring for 1h, adding 0.132g 10wt% polyvinylidene fluoride (PVDF) solution, the solvent is NMP, stirring for 5h, adjusting the scraper to 200μm, scrape coating on the aluminum film to form a film , after overnight drying at 70°C, cut into small discs with a diameter of 14mm, weighed, and vacuum-dried at 60°C for 24 hours, then use this small disc as the positive electrode (the sulfur loading on a single piece is about 1 mg cm -2 ), lithium sheet as negative electrode, clegard 2325 as separator, 1M bis(trifluoromethylsulfonyl)imide lithium solution (LiTFSI) as electrolyte solution, solvent as 1,3-dioxolane (DOL) and ethylene dioxane A mixture of alcohol dimethyl ether (DME)...

Embodiment 2

[0036] Disperse the ternary material and elemental sulfur in the ethanol solution at a ratio of 5:5 (the amount of ethanol added is suitable for infiltrating the powder material), and ball mill at 300r / min for 5 hours to obtain product A. Take 0.1gA and add 24.7mg of commercial KB After the carbon powder is uniformly mixed, disperse in 1.3g of N-methylpyrrolidone (NMP). After the dispersion is uniform, ultrasonically for 20min, stir for 1h, add 0.132g of 10wt% polyvinylidene fluoride (PVDF) solution, the solvent is NMP, and stir for 5h , adjust the scraper to 200μm, scrape and coat on the aluminum film to form a film, dry it overnight at 70°C, cut it into a small disc with a diameter of 14mm, weigh it, and vacuum dry it at 60°C for 24h, then use this small disc as the positive electrode (Single-chip sulfur load is about 1mg cm -2 ), lithium sheet as negative electrode, clegard 2325 as separator, 1M bis(trifluoromethylsulfonyl)imide lithium solution (LiTFSI) as electrolyte solu...

Embodiment 3

[0038] Dissolve 0.35g of lithium sulfide in ethanol solution, add 0.15g of lithium ion battery positive electrode material, stir and mix for 3 hours, then dry the ethanol at 80°C to obtain the target product of ethanolization, put the powder in a tube furnace, Ar atmosphere , Calcined at 200°C for 1 h, the target product was obtained after removal of ethanol. Take 0.1g of the product, add 24.7mg of commercial KB carbon powder and mix evenly, then disperse in 1.3g of N-methylpyrrolidone (NMP). (PVDF) solution, the solvent is NMP, stirred for 5h, adjusted the scraper to 200μm, scraped on the aluminum film to form a film, dried overnight at 70°C, cut into small discs with a diameter of 14mm, weighed, vacuumed at 60°C After drying for 24 hours, the small disc was used as the positive electrode (the sulfur loading capacity of the single disc was about 1 mg cm -2 ), lithium sheet as negative electrode, clegard 2325 as separator, 1M bis(trifluoromethylsulfonyl)imide lithium solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com