Insulated paint and preparation method thereof

A technology of insulating varnish and curing agent, applied in the direction of sustainable manufacturing/processing, climate sustainability, coating, etc., can solve problems such as static electricity, achieve the effect of reducing surface tension, reducing production costs, and increasing fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

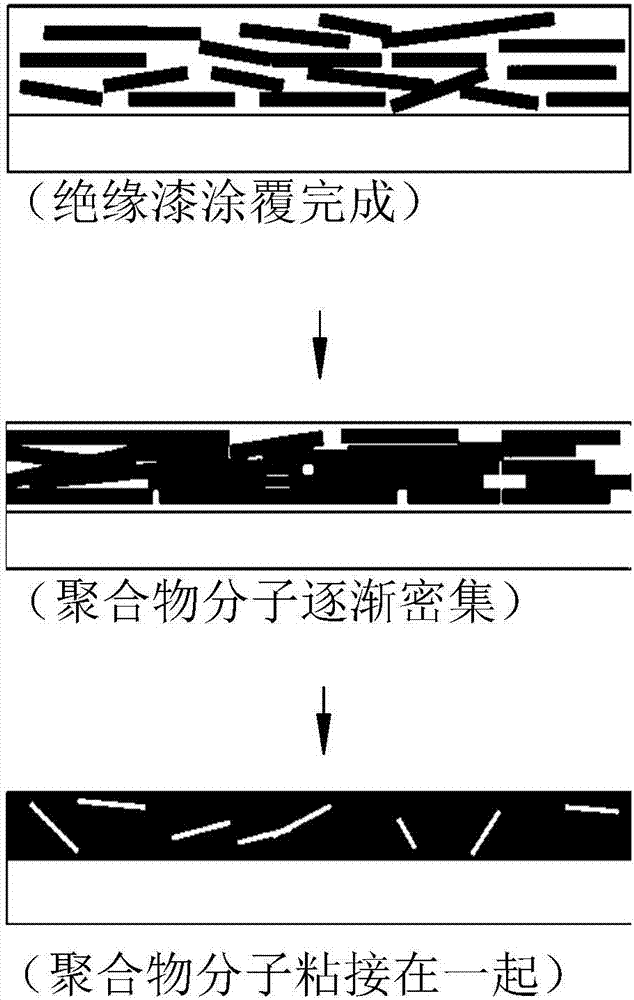

Method used

Image

Examples

Embodiment 1

[0030] An insulating varnish. The insulating varnish is prepared from the following raw materials in parts by weight: 40 parts of unsaturated polyesterimide resin, 15 parts of polyester modified epoxy resin, 8 parts of phthalate, maleic acid ester 11 parts of dianhydride, 6 parts of phthalate, 3 parts of simethicone, 1 part of clay gelling agent, 2 parts of modified polysiloxane, 4 parts of glycidyl etheroxypropyl trimethoxysilane, 5 parts of mixture of polyvinyl butyral, light calcium carbonate and cyclomethicone, 3 parts of curing agent, 4 parts of leveling agent. Unsaturated polyesterimide resin has good heat resistance, radiation resistance, stable storage, fast curing at low temperature, and can meet the requirements of insulation. Polyester modified epoxy resin has low viscosity, high functionality, no chain entanglement and good solubility, has good toughness, and can increase the mechanical strength of insulating paint; phthalates are soluble in most organic solutions,...

Embodiment 2

[0032] An insulating varnish, the insulating varnish is prepared from the following raw materials in parts by weight: 40 parts of unsaturated polyesterimide resin, 15 parts of polyester modified epoxy resin, 10 parts of phthalate, 16 parts of dimethic anhydride, 5 parts of dimethyl silicone oil, 4 parts of clay gelling agent, 6 parts of modified polysiloxane, 5 parts of glycidyl etheroxypropyl trimethoxysilane, polyvinyl butyral, light 5 parts of mixture of calcium carbonate and cyclomethicone, 4 parts of diethylenetriamine, 6 parts of mixture of melamine formaldehyde resin and polydimethylsiloxane, among which, melamine formaldehyde resin and polydimethylsiloxane It is mixed at a ratio of 3:7. After many experiments and verifications, it has been shown that although melamine formaldehyde resin has good hardness, wear resistance and electrical insulation properties, it is easy to cause the adhesive layer to break after the paint is cured, so it should not be used alone. It shou...

Embodiment 3

[0034] An insulating varnish. The insulating varnish is prepared from the following raw materials in parts by weight: 35 parts of unsaturated polyesterimide resin, 10 parts of polyester modified epoxy resin, 8 parts of phthalate, 13 parts of acid anhydride, 4 parts of dimethyl silicone oil, 2 parts of clay gelling agent, 5 parts of modified polysiloxane, 4 parts of glycidyl etheroxypropyl trimethoxysilane, polyvinyl butyral, light calcium carbonate and 4 parts of mixture of cyclomethicone, 4 parts of polyether polyester modified organosiloxane, 2 parts of ketimine curing agent, the ketimine curing agent consists of 3-methyl-2-butyl Ketone and 1,3-diaminomethylcyclohexane are prepared by Schiff reaction. Although the ketimine type can cure the epoxy resin at room temperature, the lone pair of electrons on the nitrogen atom of the imine still has a certain The ring-opening activity of the insulating varnish is not fast, so the present invention uses the ketone 3-methyl-2-butanon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com