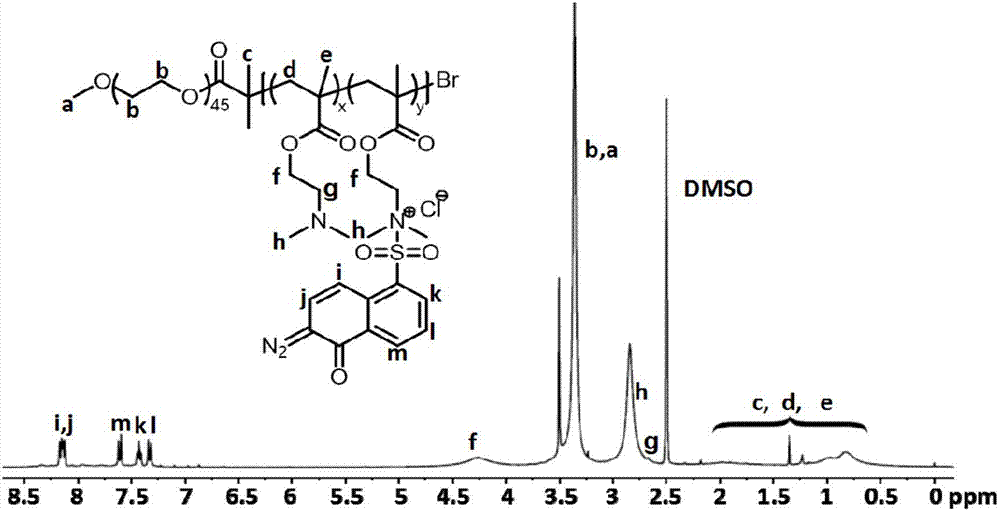

Preparation of block copolymer with quadruple responsiveness and application thereof

A technology of block copolymers and block polymers, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and photo-splitting of drugs in the body, which can solve the problem of insufficient penetration and low release efficiency , Poor tissue permeability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Step 1: Preparation of polyethylene glycol-block-polydimethylaminoethyl methacrylate: 8 mL of polymerizable monomer dimethylaminoethyl methacrylate, 200 mg of macroinitiator PEG-Br, and 14 mg of catalyst were brominated Cuprous metal was dissolved in 4 mL of dry tetrahydrofuran, placed in a Schlenk flask, and 20uL of tris(2-dimethylaminoethyl)amine was injected into the Schlenk flask with a pipette gun, and stirred for 30 minutes until complete Dissolve, nitrogen gas for 60 minutes to remove oxygen, after seven cycles of "freezing-pumping-thawing", put it in an oil bath at 55 degrees Celsius for 10 hours, and pass the product through a chromatographic column equipped with neutral alumina to remove the catalyst , and petroleum ether precipitated 4 times, and dried in a vacuum oven at 55 degrees Celsius for 24 hours to obtain a block polymer polyethylene glycol-block-polydimethylaminoethyl methacrylate.

[0031] Step 2: Prepare the polymer: According to the budgeted grafti...

Embodiment 2

[0035] Step 1: Preparation of polyethylene glycol-block-polydimethylaminoethyl methacrylate: polymerizable monomer dimethylaminoethyl methacrylate, macroinitiator PEG-Br, and catalyst cuprous bromide are dissolved In dry tetrahydrofuran, place in a Schlenk flask, use a pipette gun to inject tris(2-dimethylaminoethyl)amine into the Schlenk flask, stir for 40 minutes until completely dissolved, and pass nitrogen gas for about Oxygen was removed for 40 minutes, after six "freezing-pumping-thawing" cycles, it was placed in an oil bath at 65 degrees Celsius for 8 hours, and the product was passed through a chromatographic column equipped with neutral alumina to remove the catalyst. The ether was precipitated 3 times, the upper liquid was removed to remove the remaining deposited solid, and the solid was dried in a vacuum oven at 50 degrees for 16 hours to obtain the block polymer polyethylene glycol-block-polymethacrylic acid dimethylamino ethyl ester. The molar ratio of dimethyla...

Embodiment 3

[0039] Step 1: Preparation of polyethylene glycol-block-polydimethylaminoethyl methacrylate: 10 mL of polymerizable monomer dimethylaminoethyl methacrylate, 210 mg of macroinitiator PEG‐Br, and 30 mg of catalyst were brominated Dissolve cuprous in 7mL of dry tetrahydrofuran, place in a Schlenk flask, inject 40uL tris(2-dimethylaminoethyl)amine into the Schlenk flask with a pipette gun, and stir for 50 minutes until complete Dissolve, nitrogen gas for 30 minutes to remove oxygen, after eight cycles of "freezing-pumping-thawing", put it in an oil bath at 75 degrees Celsius for 6 hours, and pass the product through a chromatographic column equipped with neutral alumina to remove the catalyst , and petroleum ether precipitated 3 times, and dried in a vacuum oven at 50 degrees for 24 hours to obtain a block polymer polyethylene glycol-block-polydimethylaminoethyl methacrylate.

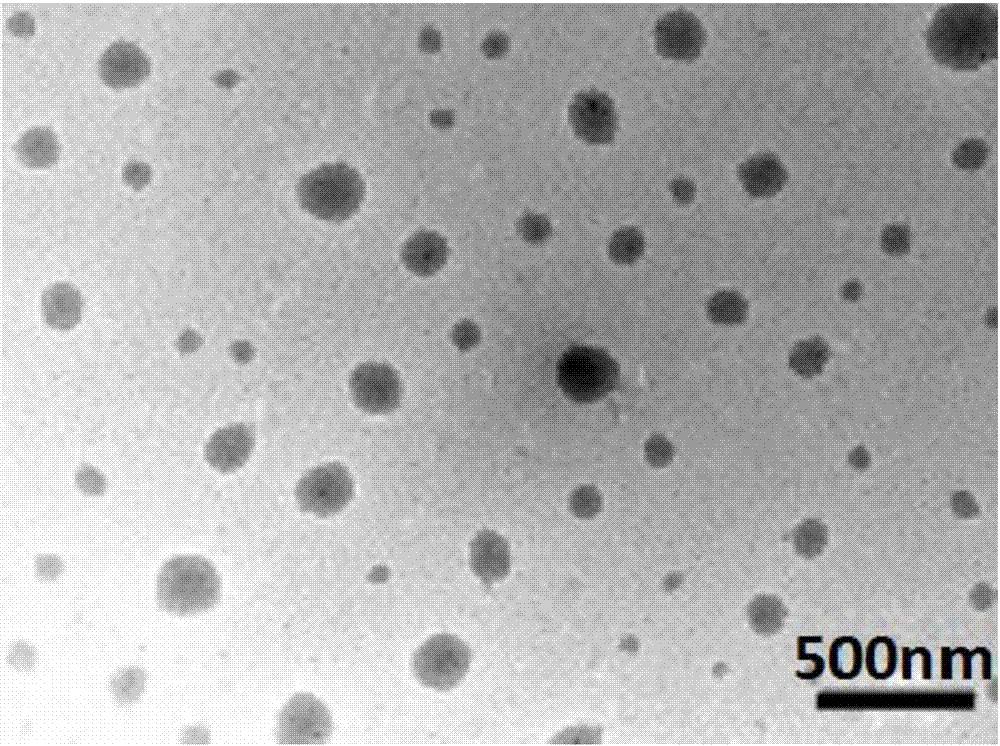

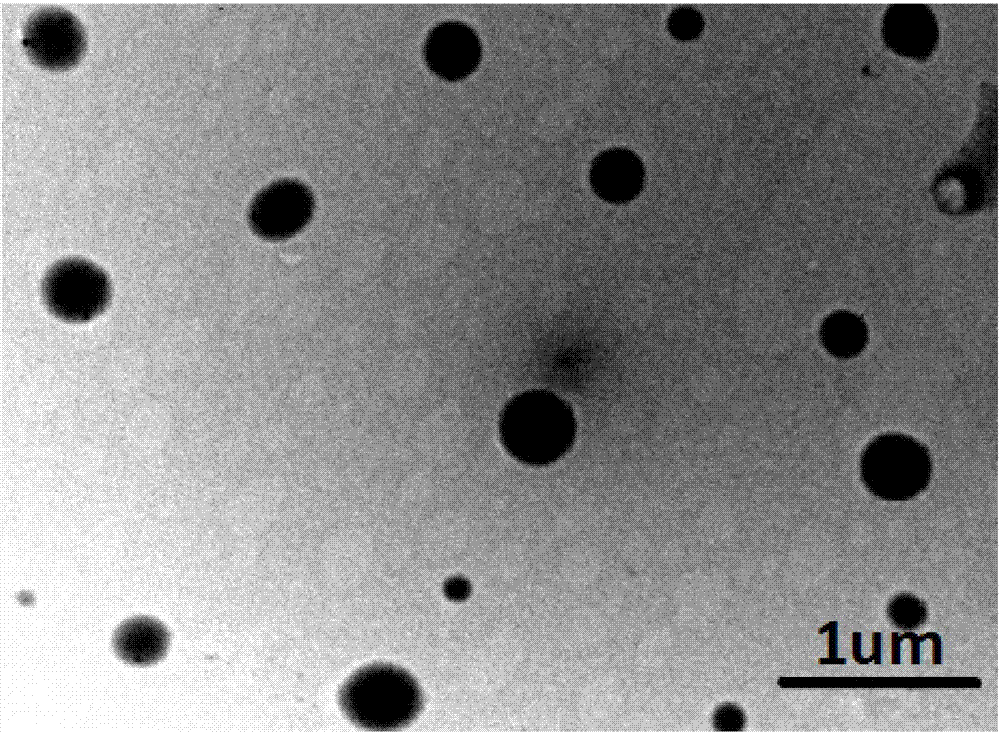

[0040] Step 2: Prepare the polymer: according to the budgeted graft ratio, add 0.6g of 2-diazo-1-naphtho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com