Preparation method of high-performance repair adhesive tape for photovoltaic module backboard

A photovoltaic module and repair tape technology, which is applied in photovoltaic modules, photovoltaic power generation, adhesive products, etc., can solve the problem of UV resistance, fogging and high temperature resistance and inconvenience of use, etc., to improve the anti-aging performance, the tape is easy to fit, and the weather resistance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

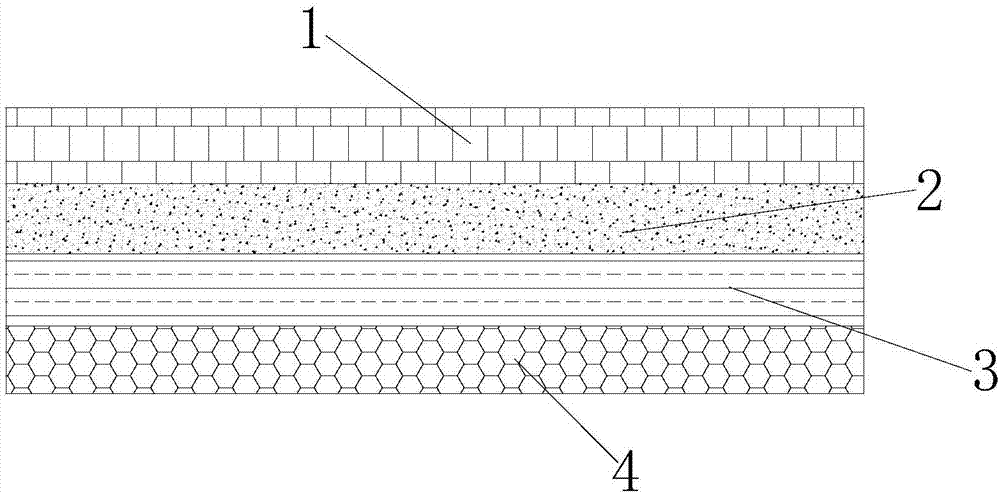

Image

Examples

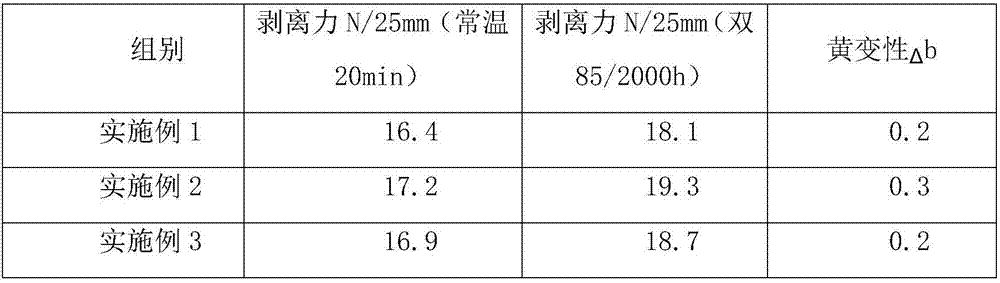

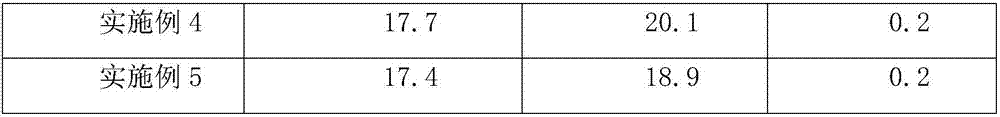

Embodiment 1

[0026] In this embodiment, the preparation of the high-performance repair tape for the backplane of the photovoltaic module comprises the following steps:

[0027] S1: coating the fluorine coating on the substrate layer with a thickness of 25 μm, and the coating thickness is 2 μm;

[0028] S2: Add 20 parts of methyl acrylate, 25.5 parts of isooctyl acrylate, 4 parts of acrylic acid, 0.5 parts of hydroxyethyl acrylate, 50 parts of butyl acrylate, and add 100 parts Ethyl acetate, introduce nitrogen and stir for half an hour, slowly heat up to 70°C, add 0.2 parts of AIBN, react for 5 hours under nitrogen protection, and finally adjust it to a synthetic glue with a solid content of 40% with ethyl acetate;

[0029] S3: Take 100 parts of synthetic glue prepared in step S2, add 0.2 parts of isocyanate curing agent L-75 (Bayer), add 20 parts of rosin resin PR-12603 (Sumitomo), add 0.03 parts of antioxidant 1010, 0.2 parts of UV absorber TINUVIN326, diluted with ethyl acetate to 20% s...

Embodiment 2

[0036] In this embodiment, the preparation of the high-performance repair tape for the backplane of the photovoltaic module comprises the following steps:

[0037] S1: coating the fluorine coating on the substrate layer with a thickness of 50 μm, and the coating thickness is 5 μm;

[0038] S2: Add 20 parts of methyl acrylate, 25.5 parts of isooctyl acrylate, 4 parts of acrylic acid, 0.5 parts of hydroxyethyl acrylate, 50 parts of butyl acrylate, and add 100 parts Ethyl acetate, introduce nitrogen and stir for half an hour, slowly heat up to 70°C, add 0.2 parts of AIBN, react for 5 hours under nitrogen protection, and finally adjust it to a synthetic glue with a solid content of 40% with ethyl acetate;

[0039] S3: Take 100 parts of synthetic glue prepared in step S2, add 0.2 parts of epoxy curing agent NX-100E (Japan Soken), add 20 parts of rosin resin PR-12603 (Sumitomo), add 0.03 parts of antioxidant Agent 1010, 0.2 parts of UV absorber TINUVIN326, diluted to 20% solid cont...

Embodiment 3

[0046] In this embodiment, the preparation of the high-performance repair tape for the backplane of the photovoltaic module comprises the following steps:

[0047] S1: coating the fluorine coating on the substrate layer with a thickness of 100 μm, and the coating thickness is 10 μm;

[0048] S2: Add 20 parts of methyl acrylate, 25.5 parts of isooctyl acrylate, 4 parts of acrylic acid, 0.5 parts of hydroxyethyl acrylate, 50 parts of butyl acrylate, and add 100 parts Ethyl acetate, introduce nitrogen and stir for half an hour, slowly heat up to 70°C, add 0.2 parts of AIBN, react for 5 hours under nitrogen protection, and finally adjust it to a synthetic glue with a solid content of 40% with ethyl acetate;

[0049] S3: Take 100 parts of synthetic glue prepared in step S2, add 0.2 part of isocyanate curing agent L-75 (Bayer), add 20 parts of petroleum resin FTR-6100 (Mitsui), add 0.03 part of antioxidant 1010, 0.2 parts of UV absorber TINUVIN326, diluted with ethyl acetate to 20% s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com