Method for high-efficiency preparation of Maillard reaction intermediate by low-temperature synthesis-decompression co-boiling dewatering coupling technology

A Maillard reaction and azeotropic dehydration technology, applied in thiol preparation, thioether preparation, food science, etc., can solve the problems that are not conducive to the industrial production of ARP and HRP, the effects of nervous system and blood system, respiratory mucosa and visual impairment and other issues, to achieve the effect of sustainable industrial design concept, high innovation, and high food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

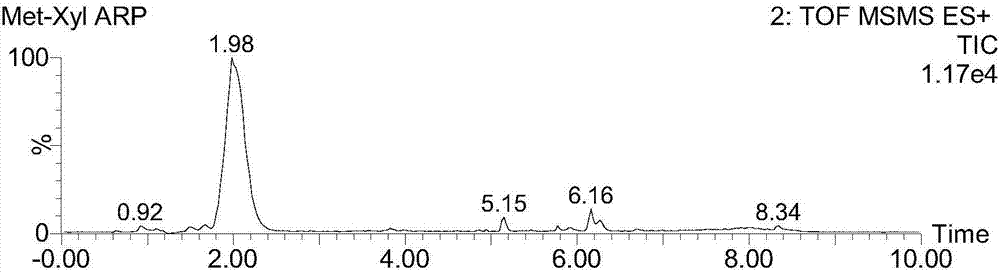

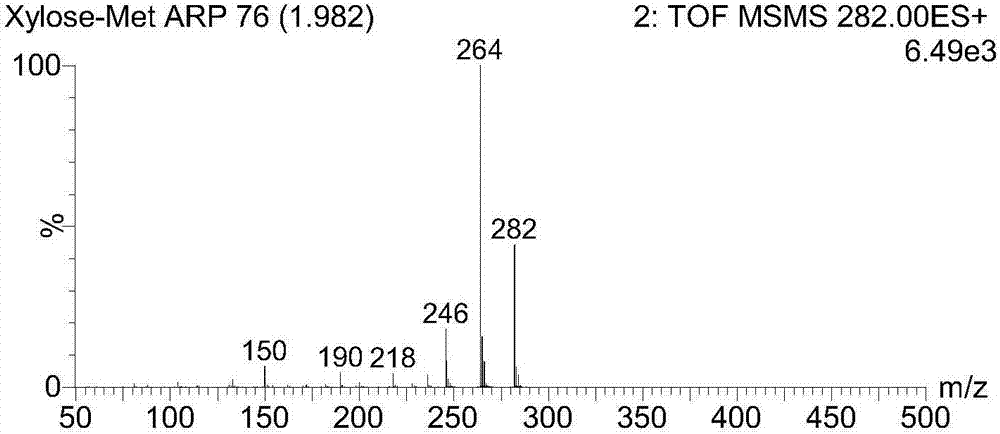

[0031] Take 20kg of methionine and 40kg of xylose, add 800kg of water to form a solution, adjust the pH of the solution to 7.5, and heat at a constant temperature of 80°C to generate a Maillard reaction. After 80 minutes, quickly reduce the system pressure to below 40mbar for dehydration. Reduce the vacuum degree of the system to 0, and stop heating at the same time to obtain dry material, add 400kg of food-grade ethanol to it, fully mix the dry material and food-grade ethanol, and then evaporate under reduced pressure at 30°C to remove food-grade ethanol and residual moisture to obtain a dry material. Fully mix the dry material with food-grade ethanol, filter under reduced pressure to obtain a clear filtrate, repeat the steps of evaporation and mixing, and finally evaporate the obtained clear filtrate under reduced pressure to obtain an intermediate solid product.

[0032] After the gained solid is dissolved in water, it is analyzed by high performance liquid chromatography t...

Embodiment 2

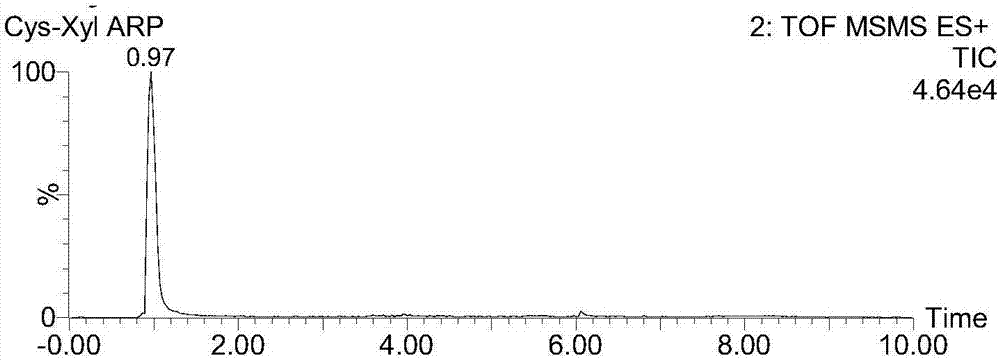

[0034] Take 8kg of cysteine and 20kg of xylose, add 800kg of water to form a solution, adjust the pH of the solution to 7.5, heat at a constant temperature of 90°C to generate a Maillard reaction, quickly reduce the system pressure to below 40mbar for dehydration after 70min, until no fraction flows out ( 15min) reduce the vacuum degree of the system to 0, and stop heating at the same time to obtain a dry material, add 400kg of food-grade ethanol to it, fully mix the dry material and food-grade ethanol, and then evaporate under reduced pressure at 30°C to remove food-grade ethanol and residual moisture to obtain a dry mass. Fully mix the dry material with food-grade ethanol, filter under reduced pressure to obtain a clear filtrate, repeat the steps of evaporation and mixing, and finally evaporate the obtained clear filtrate under reduced pressure to obtain an intermediate solid product.

[0035] After the gained solid is dissolved in water, it is analyzed by high performance...

Embodiment 3

[0037]Take 15kg of alanine and 30kg of fructose, add 700kg of water to form a solution, adjust the pH of the solution to 7.4, and heat at a constant temperature of 90°C to generate Maillard reaction. After 100min, quickly reduce the system pressure to below 40mbar for dehydration, until no fraction flows out (13min) Reduce the vacuum degree of the system to 0, and stop heating at the same time to obtain dry material, add 700kg of food-grade ethanol to it, fully mix the dry material and food-grade ethanol, and then evaporate under reduced pressure at 30°C to remove food-grade alcohol. ethanol and residual moisture to obtain a dry material. Fully mix the dry material with food-grade ethanol, filter under reduced pressure to obtain a clear filtrate, repeat the steps of evaporation and mixing, and finally evaporate the obtained clear filtrate under reduced pressure to obtain an intermediate solid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com