Preparation method of Co-BiOBr (cobalt-bismuth oxybromide)/TiO2 (titanium dioxide)/GO (graphene oxide) ternary composite photocatalyst

A photocatalyst and ternary recombination technology, applied in the field of photocatalysis, can solve problems such as hindering wide application, large band gap, and low solar energy utilization efficiency, and achieve good practicability, suppress charge recombination, solvothermal method and ultrasonic method Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

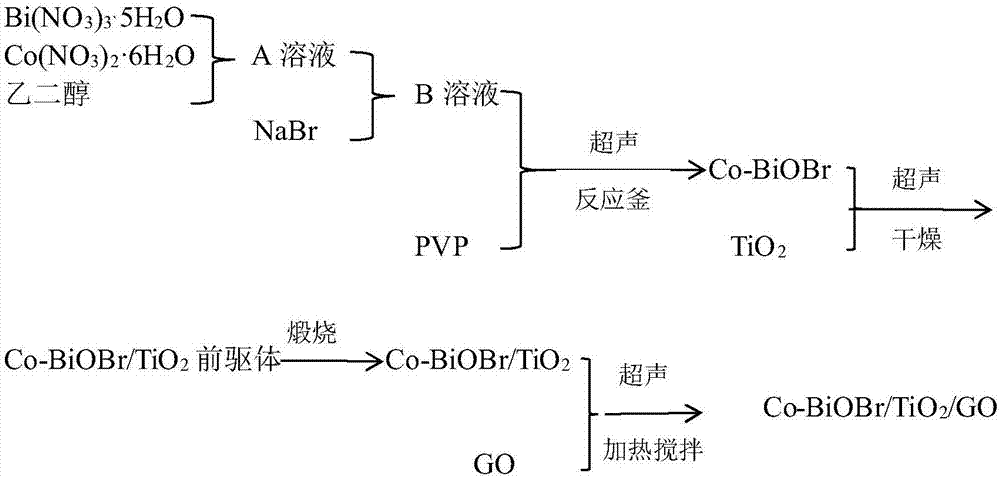

[0028] A Co-BiOBr / TiO 2 The preparation method of / GO ternary composite photocatalyst comprises the following steps:

[0029] 1) Preparation of doped Co 2+ BiOBr photocatalyst (Co-BiOBr)

[0030] Weigh Bi(NO 3 ) 3` 5H 2 O and Co(NO 3 ) 2 ·6H 2 Dissolve O in a polar organic solvent, then add a corresponding amount of NaBr, stir to dissolve, add a surfactant, stir evenly and then oscillate ultrasonically, transfer the solution after ultrasonication to a polytetrafluoroethylene high-pressure reactor for the first heat preservation reaction Post-washing, filtering, and drying to obtain the Co-BiOBr photocatalyst;

[0031] 2) Preparation of Co-BiOBr / TiO 2 binary composite photocatalyst

[0032] According to the Bi:Ti molar ratio (0.25~0.75):1, weigh the Co-BiOBr photocatalyst with the optimal doping amount prepared in step 1) and the TiO prepared by solvothermal method 2 Put them into deionized water and ultrasonically oscillate respectively, then mix the two together and...

Embodiment 1

[0040] A kind of preparation method of Co-BiOBr photocatalyst, specifically as follows:

[0041] Weigh 2.4254gBi(NO 3 ) 3` 5H 2 O and 0.0073gCo(NO 3 ) 2 ·6H 2 O was dissolved in 35mL of ethylene glycol, then weighed 0.5145gNaBr and slowly added it to the above solution, stirred until it was completely dissolved, added 0.20gPVP to it, stirred evenly, ultrasonically oscillated for 30min, and then transferred the oscillated solution to In a 50mL polytetrafluoroethylene autoclave, react at 160°C for 6 hours, wash with deionized water three times to remove excess ions and other impurities in the precipitate, wash with absolute ethanol three times to remove residual organic matter, and place in Dry in an air-blast oven at 80°C for 6 hours to obtain a 0.5% atm Co-BiOBr photocatalyst.

Embodiment 2

[0043] A kind of preparation method of Co-BiOBr photocatalyst, specifically as follows:

[0044] Weigh 2.4254gBi(NO 3 ) 3` 5H 2 O and 0.0146gCo(NO 3 ) 2 ·6H 2 O was dissolved in 35mL of ethylene glycol, then weighed 0.5145g NaBr and slowly added it to the above solution, stirred until it was completely dissolved, added 0.20g of PVP to it, stirred evenly, ultrasonically oscillated for 35min, and then transferred the oscillated solution to In a 50mL polytetrafluoroethylene autoclave, react at 165°C for 7 hours, wash with deionized water three times to remove excess ions and other impurities in the precipitate, wash with absolute ethanol three times to remove residual organic matter, and place in Dry it in an air-blast oven at 80° C. for 6 hours to obtain a 1% atm Co-BiOBr photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com