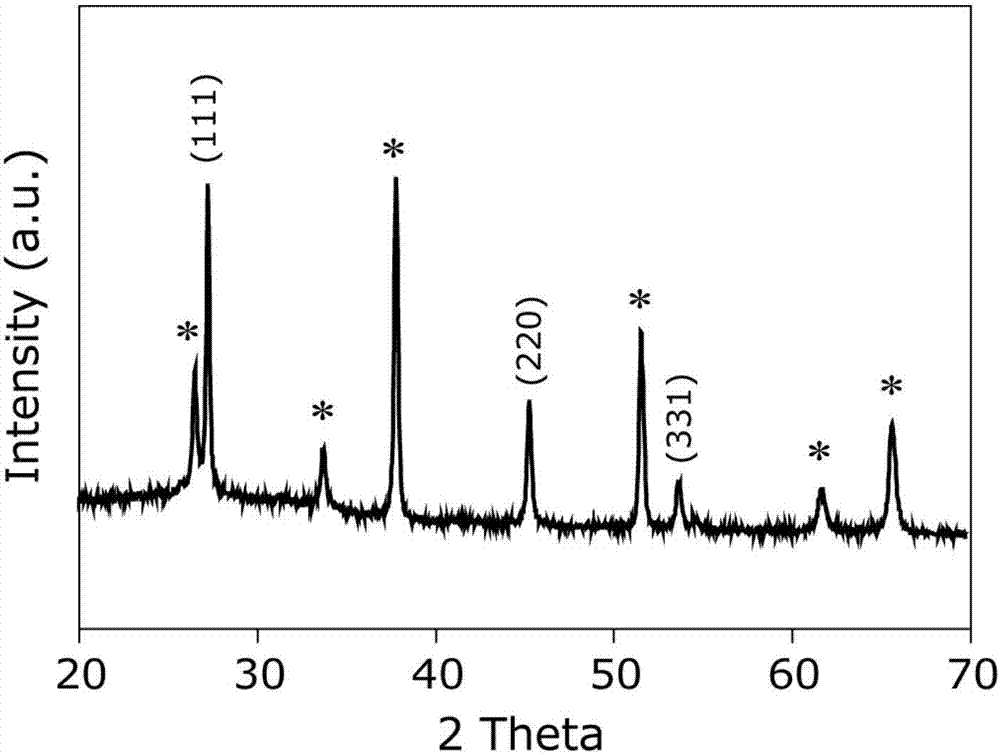

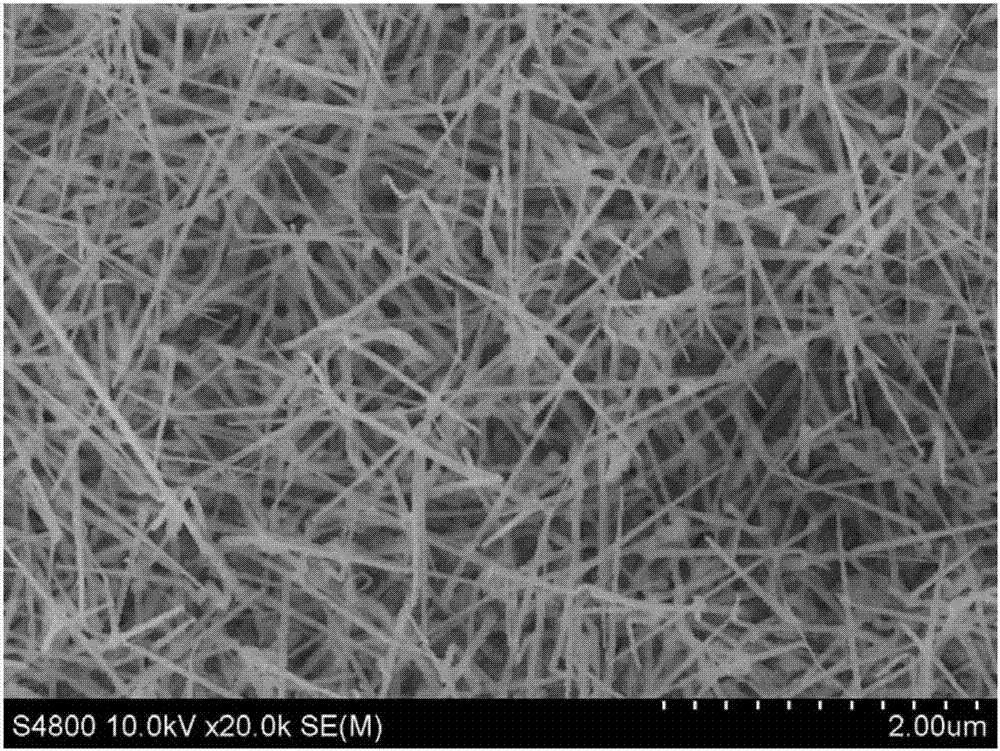

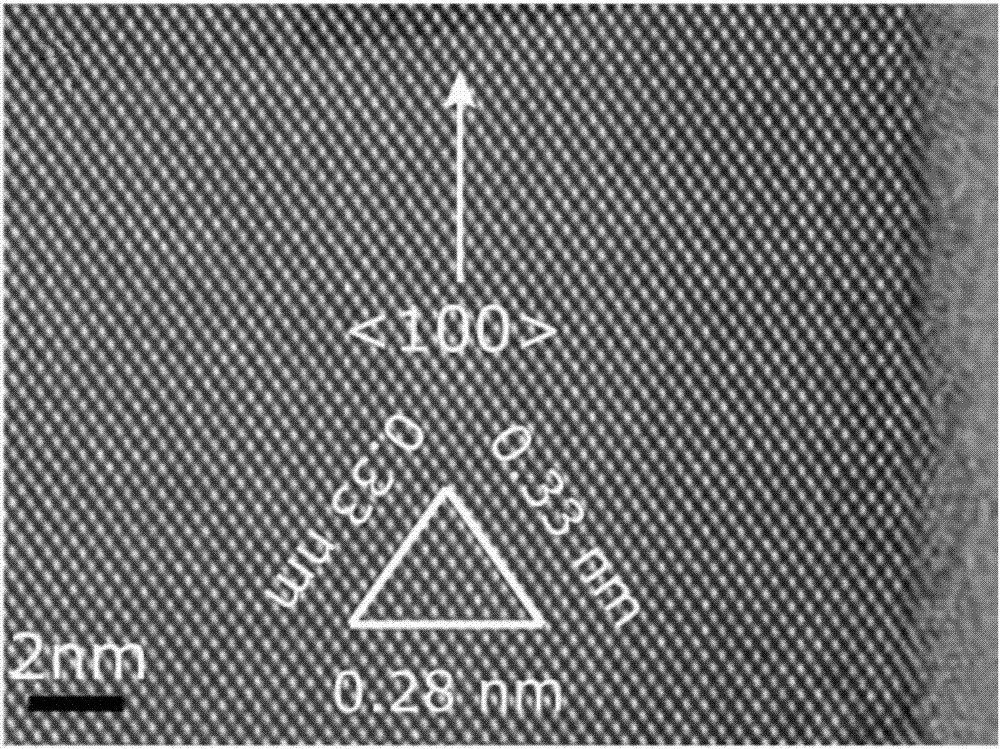

ZnSe nanowire and preparation method and application thereof

A nanowire and substrate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limiting practical applications, affecting the physical and chemical properties of nanowires, and achieving good crystallinity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Preferably, the preparation method of the ZnSe nanowires comprises the following steps:

[0065] (1) With FTO conductive glass or SnO 2 A single crystal substrate is used as a substrate, and a gold film is deposited on the surface of the substrate;

[0066] (2) step (1) is deposited with the substrate of gold film in vacuum calcining;

[0067] (3) placing the substrate calcined in step (2) and the quartz boat equipped with ZnSe powder in the large quartz tube of the dual-temperature zone tube furnace;

[0068] (4) evacuate the tube furnace described in step (3), feed protective gas simultaneously, heat the temperature zone that substrate and quartz boat are respectively housed respectively, cool naturally after the same time of insulation, on the substrate Obtain ZnSe nanowires.

Embodiment 1

[0071] The process of preparing ZnSe nanowires is as follows:

[0072] (1) Use isopropanol, acetone, and ethanol to ultrasonically clean the FTO conductive glass substrate in sequence;

[0073] (2) Deposit a 0.5nm thick gold film on the surface of the FTO conductive glass substrate as the catalyst required for ZnSe nanowire growth;

[0074] (3) Calcining the FTO conductive glass substrate deposited with the gold film at 540° C. for 30 min in a vacuum;

[0075] (4) 35mg ZnSe powder is packed in the quartz boat, the quartz boat that ZnSe powder is housed and the FTO conductive glass substrate that is deposited with gold film through calcining process are put into the large quartz tube of double-temperature zone tubular furnace, Adjust the positions of the quartz boat and the substrate to be in the center of the first temperature zone and the second temperature zone of the tube furnace;

[0076] (5) Connect the tube furnace, turn on the vacuum pump, evacuate from the side of th...

Embodiment 2

[0085] The process of preparing ZnSe nanowires is as follows:

[0086] (1) Ultrasonic cleaning of SnO with isopropanol, acetone, and ethanol in sequence 2 Single crystal substrate;

[0087] (2) to SnO 2 A 0.5nm thick gold film is deposited on the surface of the single crystal substrate as the catalyst required for the growth of ZnSe nanowires;

[0088](3) SnO deposited with a gold film 2 The single crystal substrate was calcined at 530°C for 28min in vacuum;

[0089] (4) 20mg ZnSe powder is packed into a quartz boat, and the quartz boat equipped with ZnSe powder and the SnO deposited with a gold film through calcination 2 Put the single crystal substrate into the large quartz tube of the dual temperature zone tube furnace, adjust the positions of the quartz boat and the substrate to be in the center of the first temperature zone and the second temperature zone of the tube furnace respectively;

[0090] (5) Connect the tube furnace, turn on the vacuum pump, evacuate from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com