Method for preparing anti-pollution surface of prism type surface plasmon resonance chip based on modification of hyaluronic acid coupled lubricin proteins

A technology of surface plasma and hyaluronic acid, which is applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of surface contamination of sensor chips, false positives, and reduce the accuracy of quantitative detection, and achieve anti-pollution performance. No change, strong anti-pollution performance, simple and fast preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

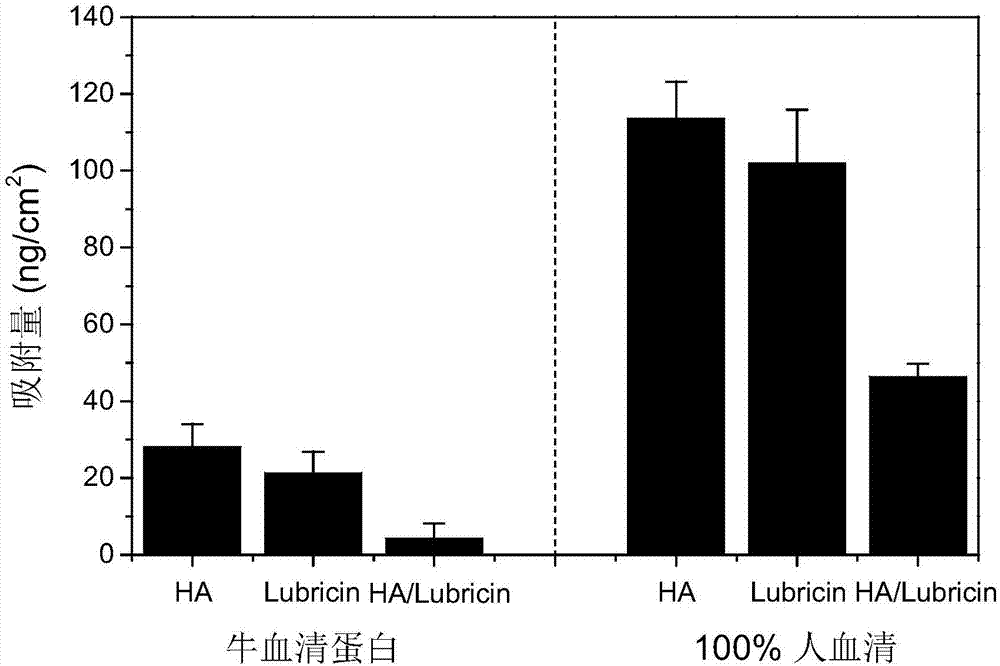

[0027] A 2nm-thick chromium layer was coated on the BK7 glass substrate by electron beam evaporation coating technology, and a 48nm-thick gold film was coated on the chromium layer to obtain a bare gold chip; the obtained bare gold chip was put into ultraviolet light Clean in an ozone cleaner for 20 minutes, take it out, wash it with ethanol and deionized water three times in sequence, and then blow dry with nitrogen; use degassed pure water to prepare a 1 mg / mL hyaluronic acid (HA) solution containing mercaptolation, and dry it After the chip was attached to the prism of the surface plasmon resonance system with asphalt, the phosphate buffer solution with a pH of 7.4 was used as the mobile phase, and the flow rate was 50 μL / min to continuously flow over the chip surface. When the baseline was stable, 100 μL of 1 mg / mL thiolated hyaluronic acid solution, and flowed through the flow cell at a rate of 20 μL / min. When the signal became stable, 100 μL of the above thiolated hyaluro...

Embodiment 2

[0029]A 2nm-thick chromium layer was coated on the BK7 glass substrate by electron beam evaporation coating technology, and a 47nm-thick gold film was coated on the chromium layer to obtain a bare gold chip; the obtained bare gold chip was put into ultraviolet light Clean in an ozone cleaner for 20 minutes, take it out, wash it with ethanol and deionized water three times in turn, and then blow dry with nitrogen; prepare a 2 mg / mL hyaluronic acid (HA) solution containing sulfhydrylation with degassed pure water, and dry it After the chip was attached to the prism of the surface plasmon resonance system with asphalt, the phosphate buffer solution with a pH of 7.4 was used as the mobile phase, and the flow rate was 100 μL / min to continuously flow over the surface of the chip. When the baseline was stable, inject 100 μL of 2 mg / mL thiolated hyaluronic acid solution, and flowed through the flow cell at a rate of 10 μL / min. When the signal became stable, inject 100 μL of the above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com