Preparation method and application of bismuth metal auto-doping halogenated bismuth oxide

A bismuth oxyhalide, self-doping technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., to achieve the effects of high detection sensitivity, low cost consumption, and obvious practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

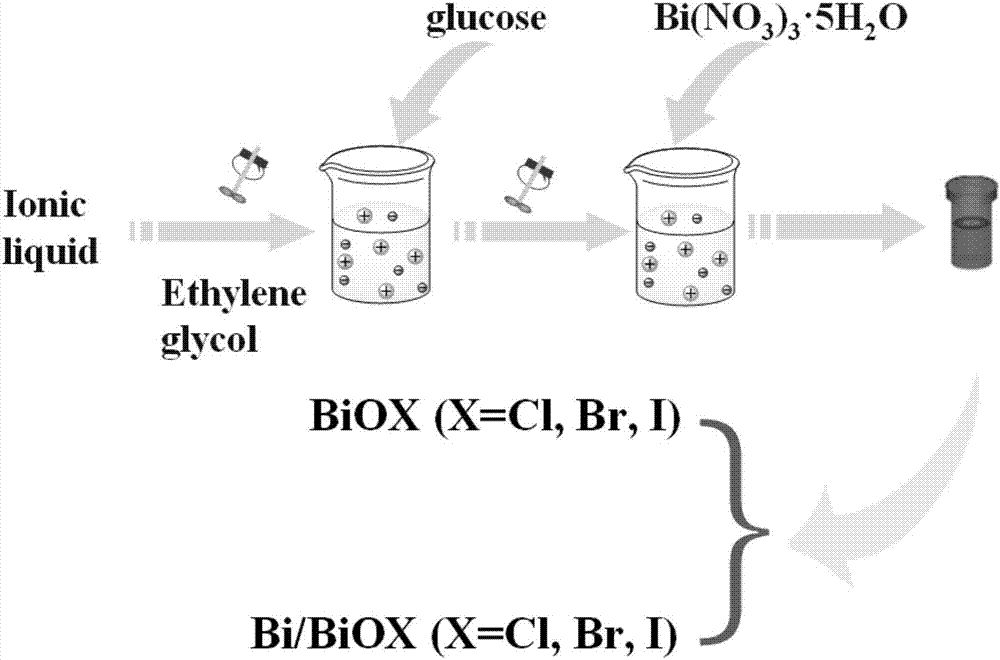

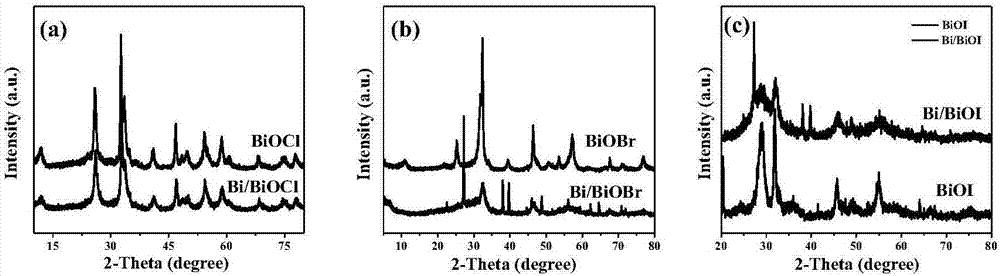

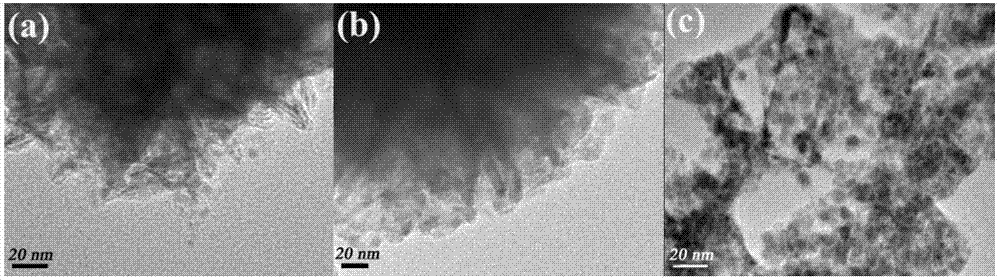

Embodiment 1

[0036] (1) The preparation of bismuth oxychloride monomer material is that solvothermal reaction one-step method makes: at first, take the 1-hexadecyl-3-methylimidazolium chloride salt of 1mmol ([C 16mim]Cl) ionic liquid into a 25mL polytetrafluoroethylene-lined reactor, secondly, pipette 20mL of ethylene glycol solution into the kettle, and fully dissolved. Add 1 mmol of bismuth nitrate pentahydrate into the kettle, and keep stirring for half an hour until the mixture is uniform. After reacting at 160°C for 24h, it was naturally cooled to room temperature; the final product was washed with alcohol, washed with water, centrifuged, and dried at 50°C for 12h to obtain BiOCl.

[0037] (2) The preparation of bismuth oxychloride material self-doped with bismuth metal is to reduce bismuth nitrate pentahydrate to obtain by glucose: first, weigh 1mmol of 1-hexadecyl-3-methylimidazolium chloride salt ( [C 16 mim]Cl) ionic liquid into a 25mL polytetrafluoroethylene-lined reactor, seco...

Embodiment 2

[0042] (1) The preparation of bismuth oxybromide monomer material is that solvothermal reaction one-step method makes: at first, take the 1-hexadecyl-3-methylimidazolium bromide ([C 16 mim] Br) of the ionic liquid into a 25mL polytetrafluoroethylene-lined reactor, and secondly, pipette 20mL of ethylene glycol solution into the kettle, and fully dissolved. Add 1 mmol of bismuth nitrate pentahydrate into the kettle, and keep stirring for half an hour until the mixture is uniform. After reacting at 140°C for 24h, it was naturally cooled to room temperature; the final product was washed with alcohol, washed with water, centrifuged, and dried at 50°C for 12h to obtain BiOBr.

[0043] (2) The preparation of bismuth oxybromide material self-doped with bismuth metal is to reduce bismuth nitrate pentahydrate to obtain by glucose: first, weigh 1mmol of 1-hexadecyl-3-methylimidazolium bromide ( [C 16 mim] Br) of the ionic liquid into a 25mL polytetrafluoroethylene-lined reactor, and se...

Embodiment 3

[0048] (1) The preparation of bismuth oxyiodide monomer material is obtained by solvothermal reaction one-step method: first, the ionic liquid of 1-butyl-3-methylimidazolium iodide salt ([Bmim]I) that takes 1mmol is put into 25mL In a polytetrafluoroethylene-lined reaction kettle, secondly, pipette 20mL of ethylene glycol solution into the kettle and fully dissolve it. Add 1 mmol of bismuth nitrate pentahydrate into the kettle, and keep stirring for half an hour until the mixture is uniform. After reacting at 160°C for 24h, it was naturally cooled to room temperature; the final product was washed with alcohol, washed with water, centrifuged, and dried at 50°C for 12h to obtain BiOI.

[0049] (2) Bismuth metal self-doped bismuth oxyiodide material is prepared by reducing bismuth nitrate pentahydrate by glucose: first, weigh 1 mmol of 1-butyl-3-methylimidazolium iodide ([Bmim ] The ionic liquid of I) is put into 25mL polytetrafluoroethylene-lined reactor, secondly, pipette 20mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com