Odor adsorbent, and preparation method and use thereof

An adsorbent and odor technology, which is applied in the field of odor adsorbent and its preparation, can solve the problems of fusel oil effect influence and complex composition, and achieve the effect of rich capillary, stable chemical properties and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

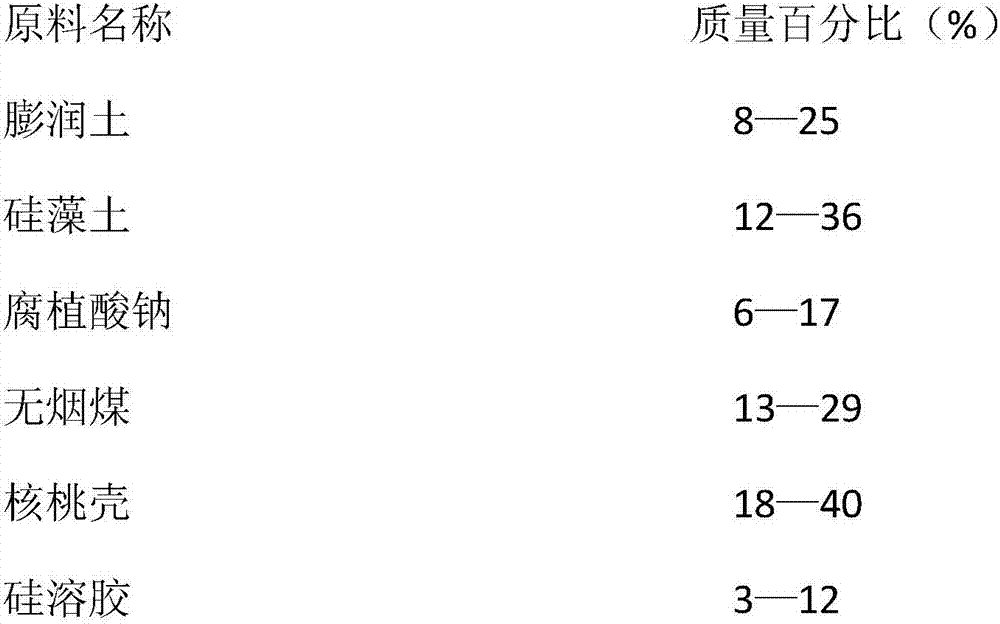

[0029] The composition of the odor adsorbent

[0030]

[0031] Pulverize bentonite, diatomite, sodium humate, anthracite and walnut shells into 60-80 mesh granules, add 17g of bentonite, 16g of diatomite, 6g of sodium humate, 15g of anthracite and 38g of walnut shells into the mixer to mix, After mixing evenly, add 8g of silica sol, mix evenly, make 30-40 mesh (450-425 micron) particles in a molding machine, and put them in a dryer for drying. Into the steel pipe in an oxygen-free environment, heated to 800 ℃. Cool, activate with 5% calcium hypochlorite solution steam to obtain odor adsorbent.

[0032] Take 50g of coal-made methanol fusel oil odor adsorbent and put it into a chromatography column, add coal-made methanol fusel oil for chromatography, and obtain 5000ml of colorless and odorless fusel oil.

Embodiment 2

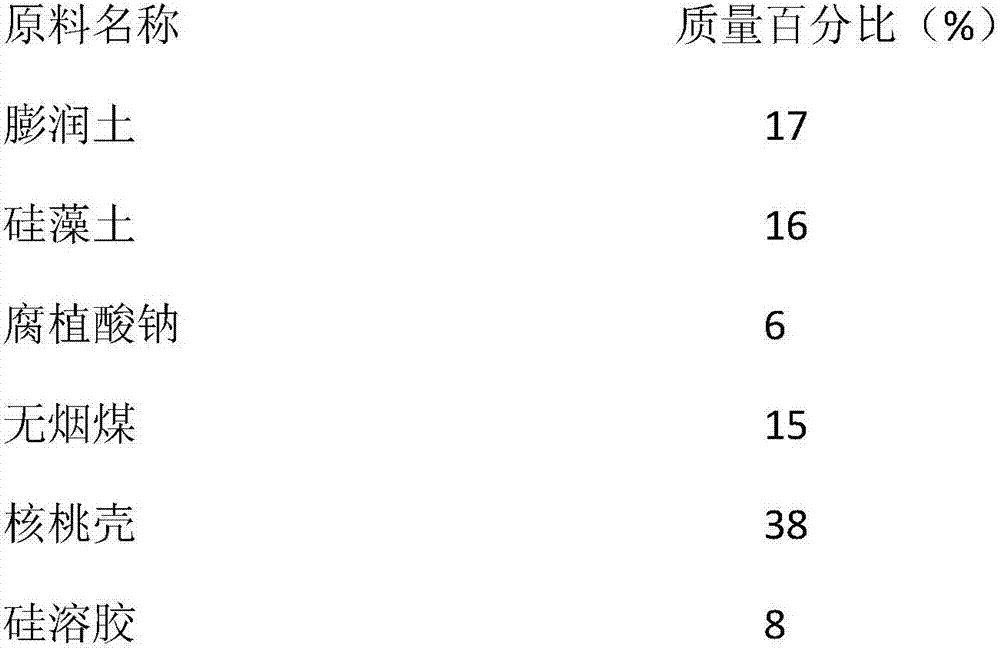

[0034] Composition of coal-to-methanol fusel oil odor adsorbent

[0035]

[0036] The above raw materials are crushed into 60-80 mesh granules as required, and bentonite, diatomite, sodium humate, anthracite and walnut shells are added to the mixer to mix, and after mixing evenly, add silica sol and mix evenly, and make it in the molding machine. The particles of 30-40 mesh (450-425 microns) are put into a dryer for drying. Into the steel pipe in an oxygen-free environment, heated to 850 ℃. Cool, activate with 5% calcium hypochlorite solution vapor.

[0037] Take 100g of coal-made methanol fusel oil odor adsorbent and put it into a chromatography column, add coal-made methanol fusel oil for chromatography, and obtain 12000ml of colorless and odorless fusel oil.

Embodiment 3

[0039] The composition of the odor adsorbent

[0040]

[0041]

[0042] Pulverize bentonite, diatomite, sodium humate, anthracite and walnut shells into 60-80 mesh granules, add 8g of bentonite, 18g of diatomite, 10g of sodium humate, 20g of anthracite and 36g of walnut shells into the mixer to mix, After mixing evenly, add 8g of silica sol, mix evenly, make 30-40 mesh (450-425 micron) particles in a molding machine, and put them in a dryer for drying. Into the steel pipe in an oxygen-free environment, heated to 900 ℃. Cool, activate with 5% calcium hypochlorite solution steam to obtain odor adsorbent.

[0043] Take 50g of coal-made methanol fusel oil odor adsorbent and put it into a chromatography column, add coal-made methanol fusel oil for chromatography, and obtain 5000ml of colorless and odorless fusel oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com