Method for preparing mesoporous carbon powder with high specific surface area

A high specific surface area, mesoporous carbon technology, applied in carbon preparation/purification, etc., can solve the problems of single pore size, difficult to control, complicated process, etc., and achieve the effect of not easy to agglomerate, low equipment requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

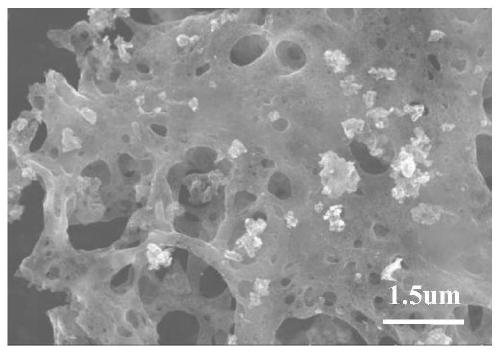

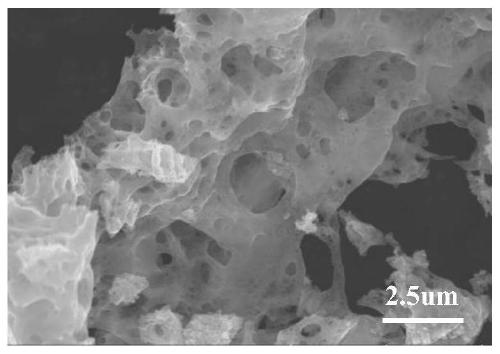

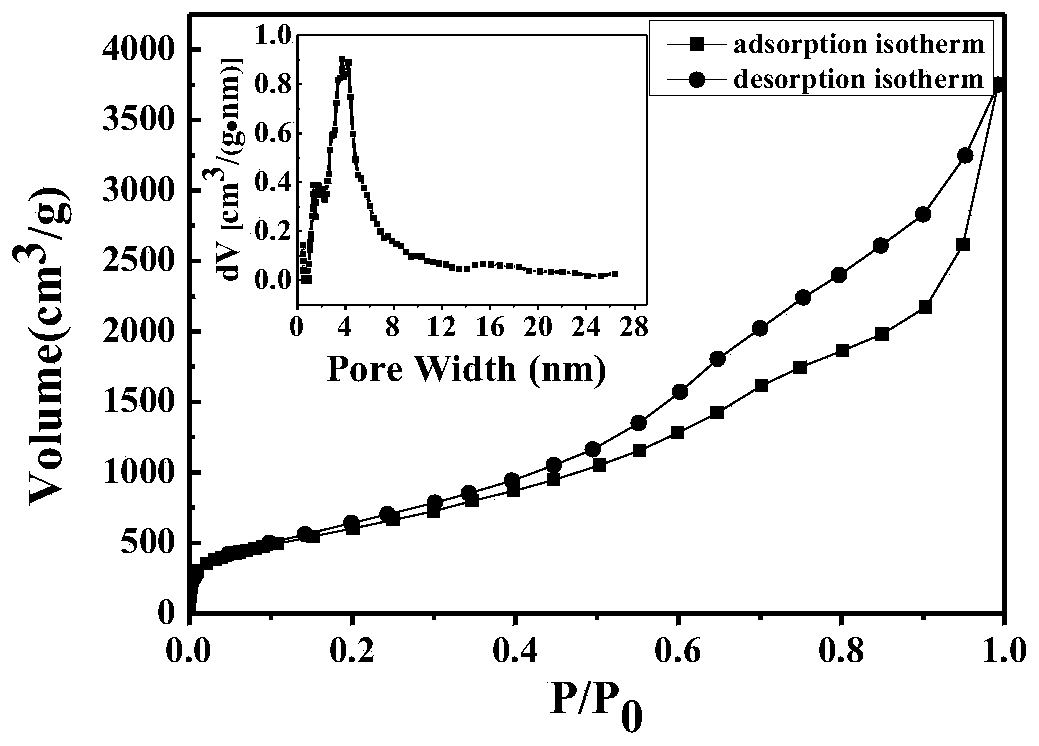

Embodiment 1

[0032] Weigh 1.28g magnesium nitrate, 1.488g zinc nitrate, 1.18g calcium nitrate, 1.088g glycine, 0.70g citric acid and 0.56g glucose into a 300ml beaker, and add deionized water to obtain a clear aqueous solution, put the solution in Heating is carried out on the resistance furnace, and the solution combustion synthesis reaction occurs. From the beginning of heating, the solution is heated until the solution is gelled and covered with a rubber stopper. After the reaction, a fluffy precursor can be obtained. Put the precursor into a tube furnace and feed it with Ar to carry out high-temperature carbonization reaction, raise the temperature to 950 °C at a rate of 5 °C / min, keep it for 2 hours, and then cool with the furnace to obtain the intermediate product of MgO / CaO / C, ZnO It reacts with carbon and pyrolyzes Zn simple substance to evaporate at high temperature to create pores on the carbon substrate. Immerse in a prepared beaker of 0.5M excess hydrochloric acid solution, soa...

Embodiment 2

[0034] Take by weighing 1.28g magnesium nitrate, 1.488g zinc nitrate, 3.75g aluminum nitrate, 1.18g calcium nitrate, 1.24g glycine, 1.6g urea and 1.31g starch and put it into a 500ml beaker, and add deionized water to obtain a clarified aqueous solution. The solution is heated on a resistance furnace, and a solution combustion synthesis reaction occurs. From the beginning of heating, the solution is heated until it is gelled and covered with a rubber stopper. After the reaction, a fluffy precursor can be obtained. Put the precursor into a tube furnace and feed it with Ar to carry out high-temperature carbonization reaction, raise the temperature to 1200°C at a rate of 8°C / min, keep it for 1h, and then cool with the furnace to obtain MgO / Al 2 o 3 The intermediate product of / CaO / C, ZnO reacts with carbon and pyrolyzes to Zn elemental high-temperature evaporation to create pores on the carbon substrate. Immerse in a prepared beaker of 1M excess hydrochloric acid solution, soak ...

Embodiment 3

[0036]Weigh 1.18g of calcium nitrate, 3.75g of aluminum nitrate, 1.49g of zinc nitrate, 1.55g of carbohydrazide, 1.328g of citric acid and 0.75g of glucose into a 500ml beaker, and add deionized water to obtain a clear aqueous solution. Put it on a resistance furnace for heating, and a solution combustion synthesis reaction occurs. From the beginning of heating, the solution is heated until it is gelatinous and covered with a rubber stopper. After the reaction, a fluffy precursor can be obtained. Put the precursor into the tube furnace and pass N 2 , carry out high-temperature carbonization reaction, raise the temperature to 1000°C at a rate of 6°C / min, keep it for 3h, and then cool with the furnace to obtain CaO / Al 2 o 3 The intermediate product of / C, ZnO reacts with carbon and pyrolyzes to Zn elemental high-temperature evaporation to create pores on the carbon substrate. Immerse in the prepared 2M excess hydrochloric acid solution beaker, soak and stand for 48 hours, filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com