RTH type topology molecular sieve catalyst for dimethyl ether carbonylation reaction and its preparation method and application

A technology of carbonylation reaction and topological structure, which is applied in the direction of molecular sieve catalysts, catalyst activation/preparation, carbon monoxide or formate reaction preparation, etc., can solve the problems of rapid catalyst deactivation and achieve improved life, good shape selectivity, and inhibition The effect of carbon deposition and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

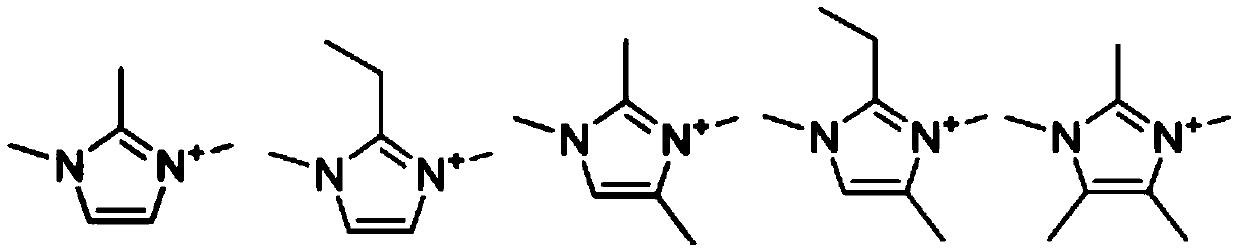

[0023] Aqueous solution of 13.4098g concentration of 20wt% 1,2,3-trimethylimidazolinium hydroxide (represented by "OSDA") was fully stirred with 0.1224g NaOH particles, then 29.3325g water glass (NaOH 2 O: 7.89wt%, SiO 2 : 25.4wt%) was added to the above solution and stirred evenly for 2 hours, then 2.1134g of HY molecular sieve with a silicon-aluminum ratio of 5.2 was added and stirred and mixed, and 31.3973g of deionized water was added and continuously stirred in a sealed container at room temperature for 2 hours until All raw materials are mixed evenly. The silica-alumina mixed sol can be used as a precursor sol for RTH molecular sieve synthesis, and has the following molar composition:

[0024] 0.26Na 2 O: SiO 2 : 0.033A1 2 o 3 :0.14OSDA:20H 2 o

[0025] Put the mixed sol in a rotary oven for dynamic crystallization at 160°C for 6 days, then recover by vacuum filtration, wash with deionized water until the pH value is less than 8.0, then dry at 120°C for 24 hours, a...

Embodiment 2~18

[0028] Same as Example 1, the difference is that the molar ratio of components in the raw material, silicon source and FAU type zeolite and the ammonium salt type used for exchange are different, specifically as shown in Tables 1 and 2, wherein the involved Y zeolite The molecular silicon to aluminum ratio is 5.2, and the molecular silicon to aluminum ratio of X zeolite is 2.8.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

[0033]

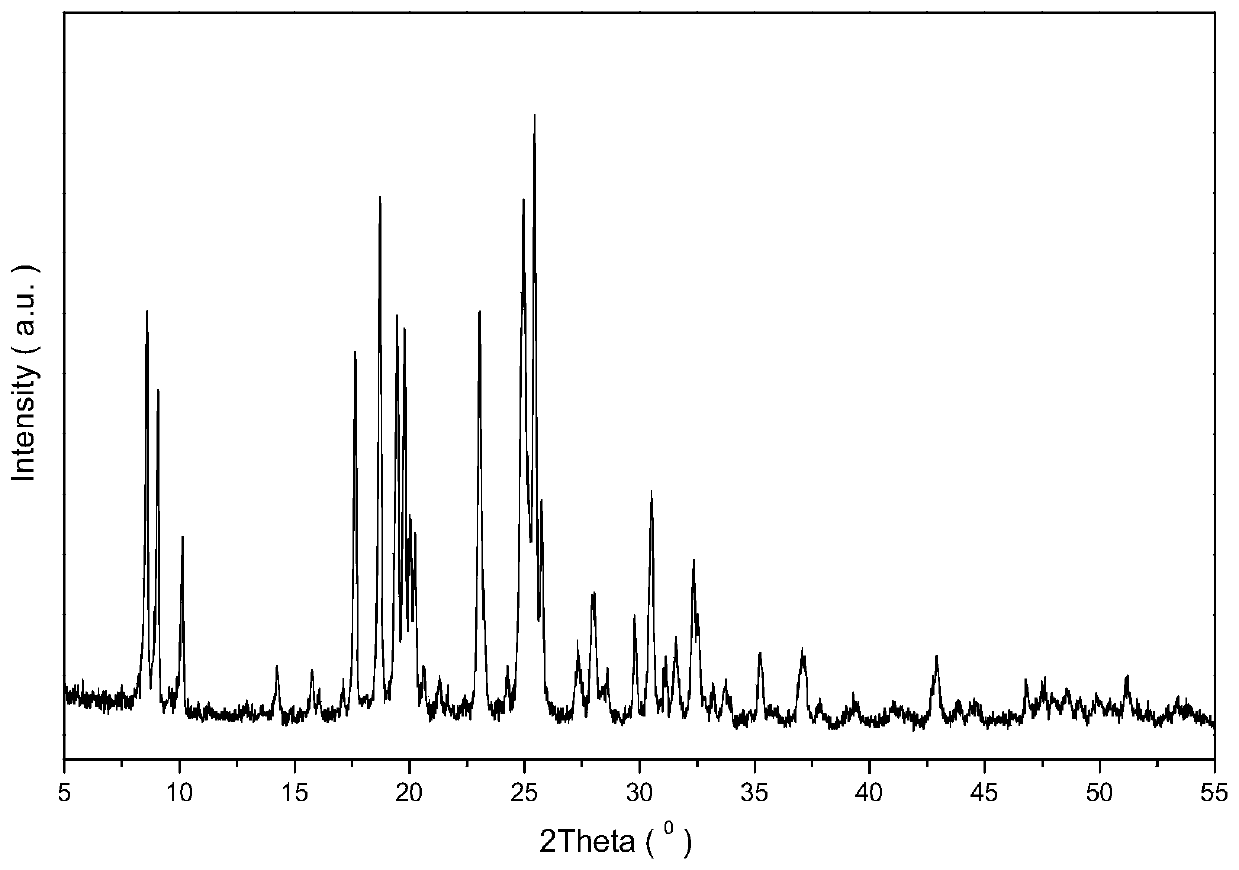

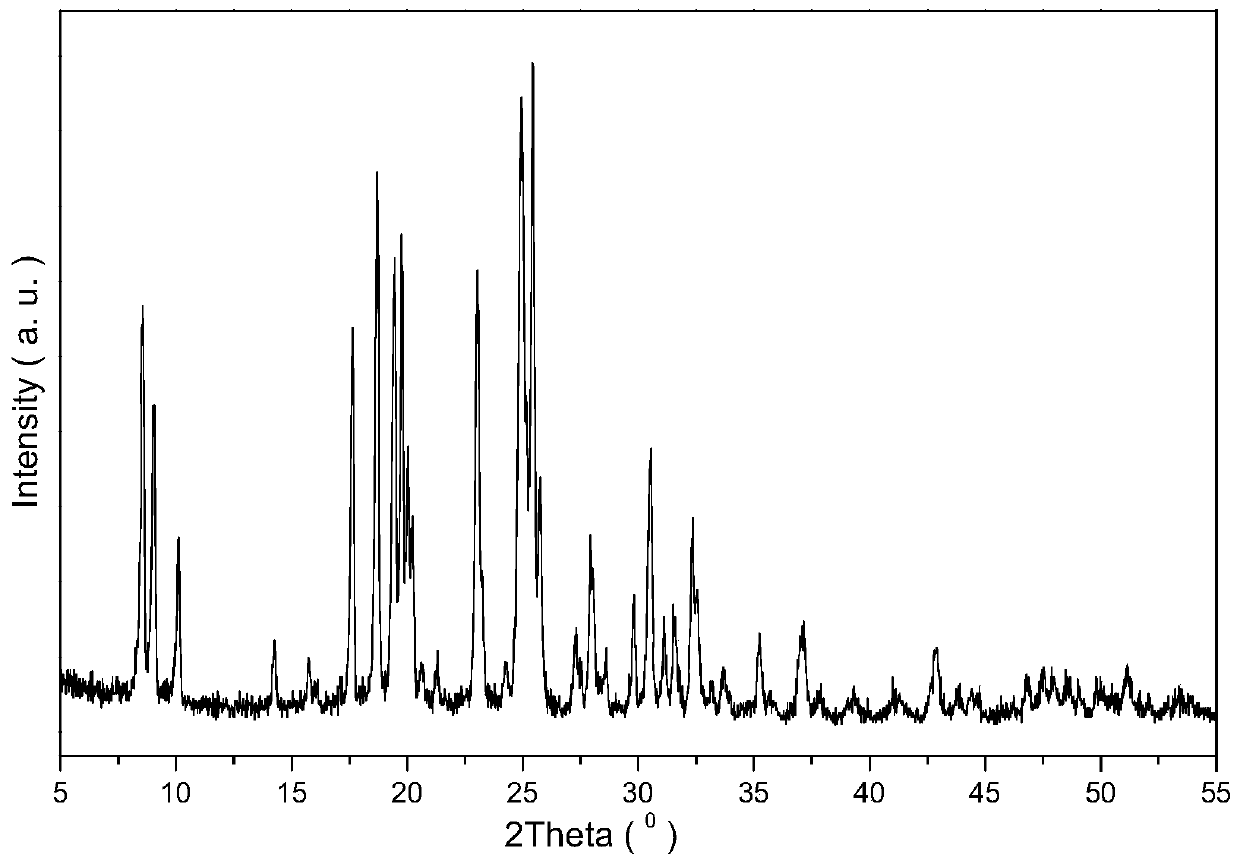

Embodiment 19

[0035] Samples 1-18 prepared in Examples 1-18 were characterized by XRD to confirm that they were RTH molecular sieves. The instrument used is a PANalytical X’Pert X-ray diffractometer, a copper target, and a Kα radiation source. The operating voltage of the instrument is 40kv, and the operating current is 40mA. The obtained XRD spectra of samples 1-18 and the characteristic spectra of standard RTH molecular sieves Figure 1 Sincerely. Typical XRD patterns (such as figure 1 ) is represented by sample 1, and the positions and peak intensities of the main diffraction peaks at 2θ between 5° and 50° are shown in Table 3. Compared with sample 1, other sample data results have the same diffraction peak position and shape, and the relative peak intensity fluctuates within ±5% according to the change of synthesis conditions, indicating that the synthesized product has the characteristics of RTH molecular sieve structure.

[0036] table 3

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com