A degreaser for oily sewage treatment in oil fields and preparation method thereof

A technology for degreasing agent and oily sewage, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Poor performance and other problems, to achieve the effect of high oil removal efficiency, simple synthesis process, and strong temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Degreaser W 1 and its preparation method

[0029] (1) Degreaser W 1 The composition, components and molecular formula are as follows:

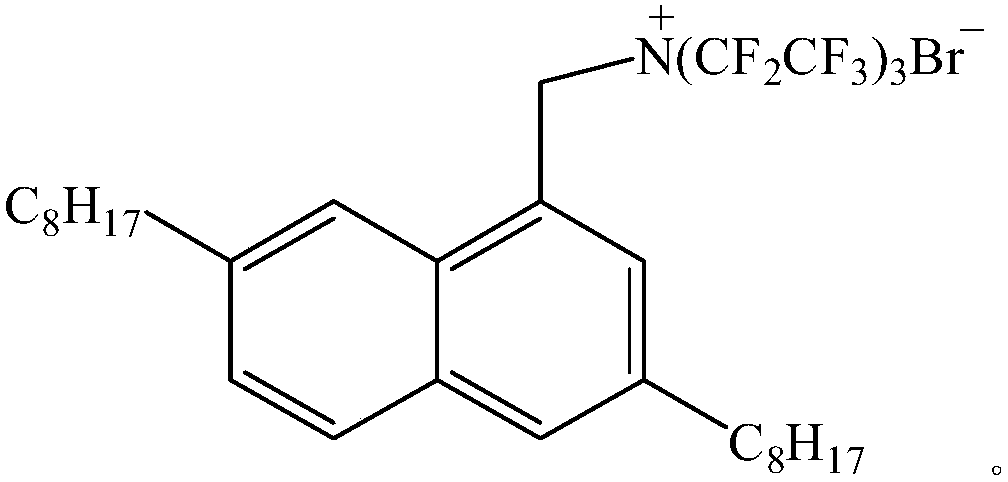

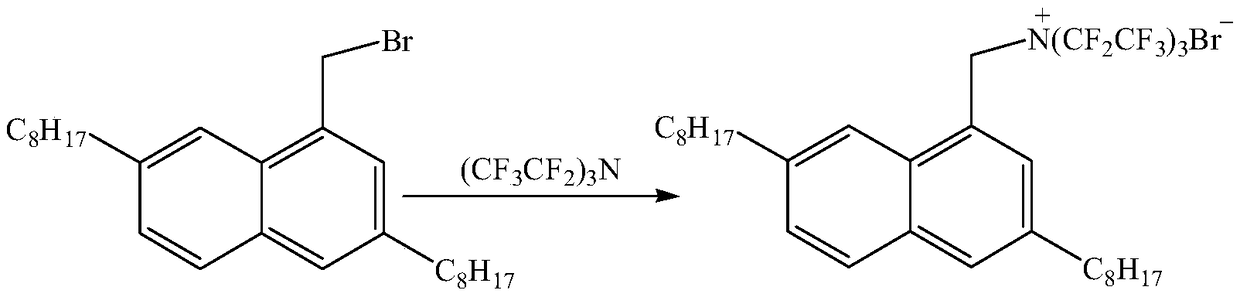

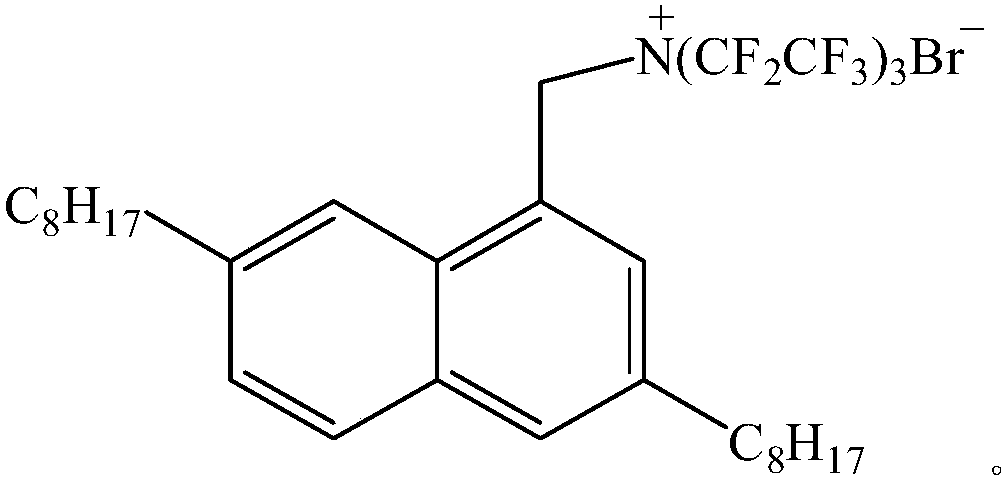

[0030] Degreaser W 1 Cationic degreasing agent is produced by reacting perfluorotriethylamine with 3,7-dioctyl-1-bromomethylnaphthalene in ethanol solution, and its molecular formula is as follows:

[0031]

[0032] The molar ratio of perfluorotriethylamine to 3,7-dioctyl-1-bromomethylnaphthalene is 1:1.0.

[0033] (2) Degreaser W 1 The preparation method is as follows:

[0034] ① Add 1 mol of perfluorotriethylamine to 7420g of ethanol, stir at 35°C, the stirring rate is 300rpm, and the stirring time is 20min, then slowly add 5.565g of catalyst potassium carbonate dropwise, react for 2h, cool down to room temperature, Obtain solution A;

[0035] ②Add 1.0mol of 3,7-dioctyl-1-bromomethylnaphthalene to solution A, slowly raise the temperature to 75°C, stir at 510rpm, react for 13h, then cool down to 40°C, react for ...

Embodiment 2

[0039] Embodiment 2: Degreaser W 2 and its preparation method

[0040] (1) Degreaser W 2 The composition, components and molecular formula are as follows:

[0041] Degreaser W 2 Cationic degreasing agent is produced by reacting perfluorotriethylamine with 3,7-dioctyl-1-bromomethylnaphthalene in ethanol solution, and its molecular formula is as follows:

[0042]

[0043] The molar ratio of perfluorotriethylamine to 3,7-dioctyl-1-bromomethylnaphthalene is 1:1.2.

[0044] (2) Degreaser W 2 The preparation method is as follows:

[0045] ① Add 1 mol of perfluorotriethylamine to 6123g of ethanol, stir at 40°C, the stirring rate is 350rpm, and the stirring time is 30min, then slowly add 4.123g of catalyst potassium carbonate dropwise, react for 2.5h, then cool down to room temperature , to obtain solution A;

[0046] ② Add 1.2mol of 3,7-dioctyl-1-bromomethylnaphthalene to solution A, slowly raise the temperature to 90°C, stir at 530rpm, react for 15h, then cool down to 50°C...

Embodiment 3

[0050] Embodiment 3: Degreaser W 3 and its preparation method

[0051] (1) Degreaser W 3 The composition, components and molecular formula are as follows:

[0052] Degreaser W 3 Cationic degreasing agent is produced by reacting perfluorotriethylamine with 3,7-dioctyl-1-bromomethylnaphthalene in ethanol solution, and its molecular formula is as follows:

[0053]

[0054] The molar ratio of perfluorotriethylamine to 3,7-dioctyl-1-bromomethylnaphthalene is 1:1.4.

[0055] (2) Degreaser W 3 The preparation method is as follows:

[0056] ① Add 1 mol of perfluorotriethylamine to 5420g of ethanol, stir at 45°C, the stirring rate is 320rpm, and the stirring time is 23min, then slowly add 3.562g of catalyst potassium carbonate dropwise, react for 2h, cool down to room temperature, Obtain solution A;

[0057] ② Add 1.4mol of 3,7-dioctyl-1-bromomethylnaphthalene to solution A, slowly raise the temperature to 80°C, stir at 500rpm, react for 12h, then cool down to 45°C, react for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com