Method for fast preparing particle size-controllable water-soluble silver selenide quantum dot

A water-soluble, silver selenide technology, applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., can solve the problems of complex preparation process, disadvantageous mass preparation, harsh reaction conditions, etc., achieve controllable particle size, shorten preparation The effect of short time and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

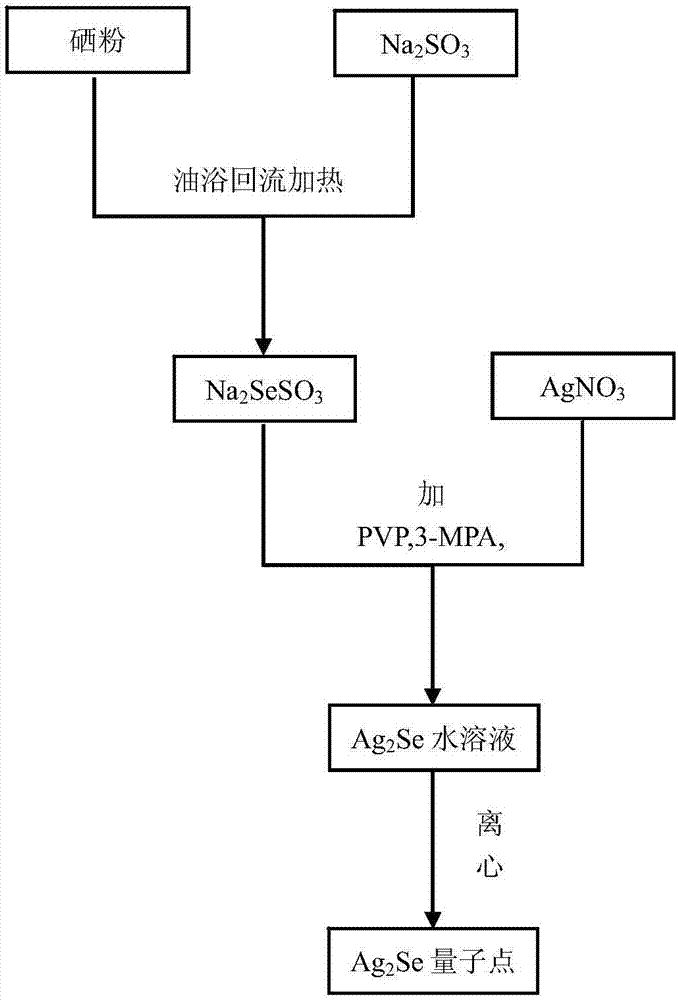

[0028] A method for quickly preparing water-soluble silver selenide quantum dots with controllable particle size of the present invention, and the process flow chart is as follows figure 1 As shown, including the following steps:

[0029] (1) Weigh 1.260g of Na at room temperature 2 SO 3 (0.01mol) and 0.789g of selenium (0.01mol) powder dissolved in 50mL deionized water, refluxed for 8h in 85℃ oil bath, when the selenium powder is completely dissolved and completely converted into a colorless transparent liquid, 0.2mol / L NaSeSO 3 Solution

[0030] (2) Dissolve 0.170g silver nitrate (0.001mol) in 250mL deionized water to obtain 4mmol / L silver nitrate solution;

[0031] (3) The 0.2mol / L NaSeSO obtained in step (1) 3 The solution is diluted 100 times with deionized water to 2mmol / L;

[0032] (4) When the temperature of the water bath is 23℃, add 5mL 4mmol / L silver nitrate solution and 0.5mL 3-MPA to the three-necked flask, magnetically stir for 3min, add 4mg PVP and stir for 1min; add amm...

Embodiment 2

[0035] A method for quickly preparing water-soluble silver selenide quantum dots with controllable particle size of the present invention, and its process flow chart is as follows figure 1 As shown, including the following steps:

[0036] (1) Weigh 1.260g of Na at room temperature 2 SO 3 (0.01mol) and 0.789g of selenium powder (0.01mol) are dissolved in 50mL of deionized water, and refluxed for 10h in an oil bath at 90℃. After the selenium powder is completely dissolved and completely converted into a colorless and transparent liquid, 0.2mol / L NaSeSO 3 Solution

[0037] (2) Dissolve 0.170g silver nitrate (0.001mol) in 166mL deionized water to obtain a 6mmol / L silver nitrate solution;

[0038] (3) The 0.2mol / L NaSeSO obtained in step (1) 3 The solution is diluted 100 times to 2mmol / L;

[0039] (4) When the temperature of the water bath is 20℃, add 5mL of 6mmol / L silver nitrate solution and 0.7mL of 3-MPA to the three-necked flask, magnetically stir for 4min, then add 3mg of triammonium ...

Embodiment 3

[0042] A method for quickly preparing water-soluble silver selenide quantum dots with controllable particle size of the present invention, and its process flow chart is as follows figure 1 As shown, including the following steps:

[0043] (1) Weigh 1.260g of Na at room temperature 2 SO 3 (0.01mol) and 0.789g selenium powder (0.01mol) dissolved in 50mL deionized water, refluxed for 12h in 95℃ oil bath, after the selenium powder is completely dissolved, it is completely converted into a colorless and transparent liquid, to obtain 0.2mol / L NaSeSO 3 Solution.

[0044] (2) Dissolve 0.170g silver nitrate (0.001mol) in 125mL deionized water to obtain 8mmol / L silver nitrate solution;

[0045] (3) The 0.2mol / L NaSeSO obtained in step (1) 3 The solution is diluted 100 times to 2mmol / L;

[0046] (4) Under the condition of a water bath temperature of 18℃, add 5mL of 6mmol / L silver nitrate solution and 0.7mL of 3-MPA to the three-necked flask, magnetically stir for 5min, then add 2mg PVP, stir for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com