Stable HRP (horse radish peroxidase) chemiluminescence substrate solution

An enzymatic chemiluminescence and substrate liquid technology, applied in the field of immunoassay, can solve the problems of inaccurate results, poor stability and high cost, and achieve the effects of high luminescence intensity value, good stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A stable HRP enzyme-catalyzed chemiluminescent substrate solution, respectively configured with 1000mL luminescent agent solution and oxidant solution, wherein the specific formula of luminescent agent solution is as follows:

[0027]

[0028] The specific formula of oxidant solution is as follows:

[0029]

[0030] In the above-mentioned luminescent agent solution, the buffer used may adopt other conventional buffer systems, such as phosphate buffer and the like.

[0031] Before use, the luminescent agent solution and the oxidant solution are mixed at a volume ratio of 1:1 before use. One day after the above-mentioned chemiluminescent substrate solution was mixed, the blank value did not increase, and the signal value was stable.

[0032] In order to ensure the stability of the above reagents after long-term storage, ProClin 300 with a mass concentration of 0.01-0.1% can be added to the oxidant solution. This mass concentration effectively guarantees the shelf l...

Embodiment 2

[0034] This embodiment configures the chemiluminescent substrate solution and the oxidizing agent solution on the basis of implementation 1, and the specific formula is as follows:

[0035] Luminescent agent solution in chemiluminescent substrate solution:

[0036] Luminol 1mmol / L

[0037] Phenolphthalein 0.1mmol / L

[0038] p-iodophenol 1.5mmol / L

[0039] 0.2mol / L boric acid-borax buffer solution, adjust the pH value to 9.6 with hydrochloric acid.

[0040] Oxidant solution in chemiluminescent substrate solution:

[0041]

[0042] 0.2mol / L citric acid buffer, adjust the pH value to 5.0 with hydrochloric acid

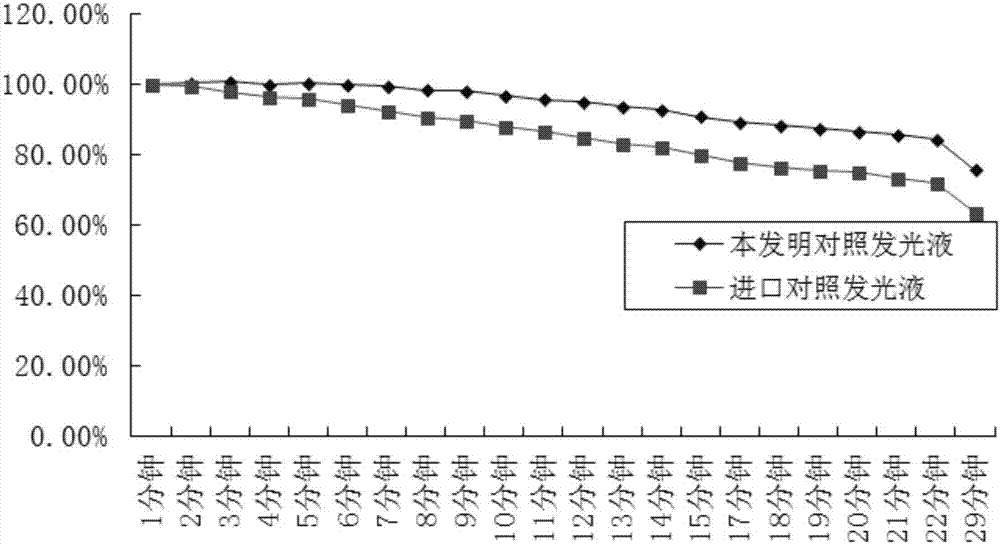

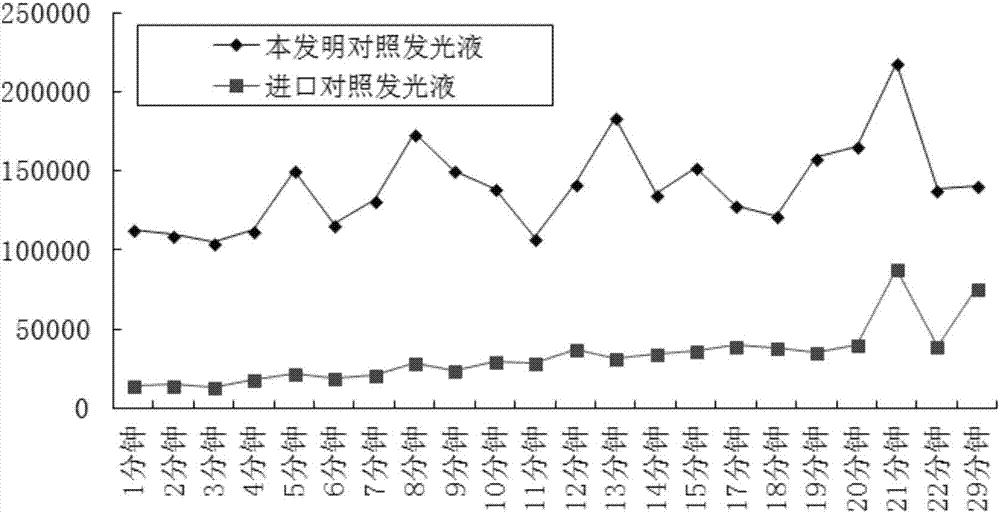

[0043] After mixing the above-mentioned luminescent agent solution and oxidant solution according to the volume ratio of 1:1, as a luminescent substrate solution and a commercially available imported ultra-sensitive luminescent substrate solution produced by ThermoFisher Pierce in the determination of 0.5 μg / mL HRP enzyme solution The signal-to-noise ratio (the ra...

Embodiment 3

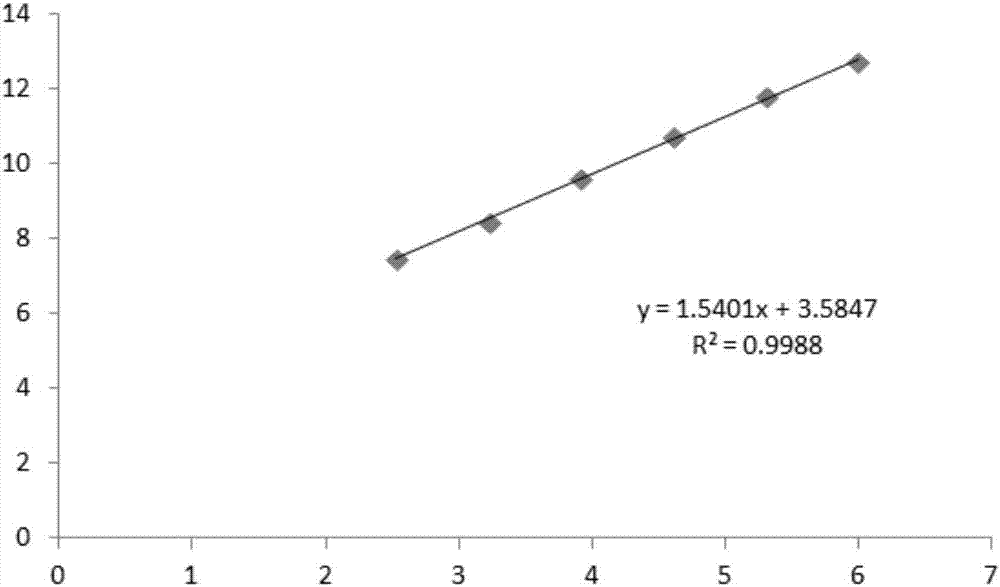

[0049] The chemiluminescent substrate solution in Example 2 was used to detect γ-interferon by the double-antibody sandwich method, wherein the antibody was produced by Wuhan Haijili Biotechnology Co., Ltd.

[0050] The experimental steps are as follows:

[0051] 1. Add sample

[0052] (1) Use the calibrator diluent to dilute the γ-interferon calibrator reference substance to a total of 6 dilution concentrations of 12.5pg / mL, 25pg / mL, 50pg / mL, 100pg / mL, 200pg / mL, and 400pg / mL. Take 50 μL, add to the wells of the plate in order, and make two parallel wells; blank control 1 well, blank control plus 50 μL of calibrator dilution;

[0053] (2) Add 50 μL of enzyme-labeled reagent to each well;

[0054] 2. Incubation: Gently mix well and incubate in a constant temperature incubator at 37°C for 1 hour;

[0055] 3. Washing: Shake off the liquid in the wells, add 300 μL of 1× washing solution to each well for washing, pat dry, repeat 5 times;

[0056] 4. Luminescence: Add 100 μL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com