Method for rapidly measuring ammonia nitrogen content of biogas fluid

A technology for rapid determination of ammonia nitrogen content, which is applied in the preparation of test samples, material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials. The problem of high measurement results is to achieve the effect of no interference factors, simple experimental principle, and low detection cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

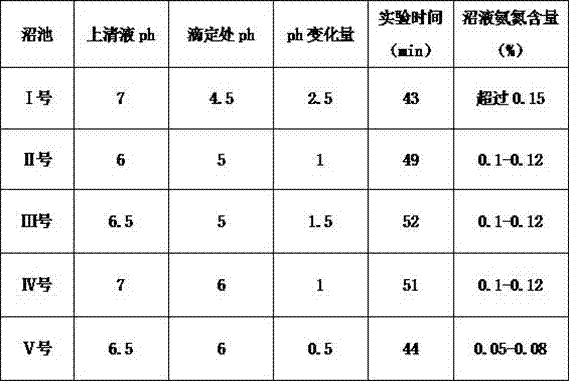

[0030] [Example 2] Sampling points were set and sampled in the upper, middle and lower layers of No. Ⅱ biogas pond respectively. There were 3 sampling points in each layer, and the volume of biogas slurry sampled at each sampling point was 200ml. All the obtained samples were mixed and filtered with a 150-mesh filter, and diluted 40 times to obtain 72L of the test solution. Heat the solution to be tested to 60 degrees Celsius, add 720mg of PAC, and gradually add 267mg of CTS under stirring. After three minutes, large flocs and clear supernatant appear in the solution. Use pH test paper to measure the pH of the supernatant to 6. Get the supernatant and drop it on the ammonia nitrogen detection test paper with a formaldehyde concentration of 71%, and obtain a pH of 5 after the reaction at the titration place.

Embodiment 3

[0031] [Example 3] Divide No. Ⅲ biogas pond into five height layers on average in the vertical direction, set two sampling points in each layer, and the volume of biogas slurry sampled at each sampling point is 200ml. All the obtained samples were mixed and filtered with a 200-mesh filter, and diluted 50 times to obtain 100L of the test solution. Heat the solution to be tested to 65 degrees Celsius, add 1.5g of PAC, and gradually add 0.5g of CTS under stirring. After a little more than one minute, large flocs and clear supernatant will appear in the solution. Use ph test paper to measure the concentration of the supernatant. pH is 6.5. Get the supernatant and drop it on the ammonia nitrogen detection test paper with a formaldehyde concentration of 78%, and obtain a pH of 5 after the reaction at the titration place.

Embodiment 4

[0032] [Example 4] Sampling points were set and sampled in the upper, middle and lower layers of No. IV marsh pond respectively. There were 3 sampling points in each layer, and the volume of biogas slurry sampled at each sampling point was 200ml. All the obtained samples were mixed and filtered with a 150-mesh filter, and diluted 40 times to obtain 72L of the test solution. Heat the solution to be tested to 60 degrees Celsius, add 720mgPAC, and gradually add 267mgCTS under stirring. After three minutes, large flocs and a clear supernatant appear in the solution. The pH of the supernatant is 7 when measured with pH test paper. Get the supernatant and drop it on the ammonia nitrogen detection test paper with a formaldehyde concentration of 71%, and obtain a pH of 6 after the reaction at the titration place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com