Organic-farming slow-release-fertilizer production method

A manufacturing method and fertilizer technology, applied in the directions of organic fertilizers, inorganic fertilizers, calcareous fertilizers, etc., can solve the problems of providing safe and high quality, different production environments, difficult to handle, etc., so as to be easy to store and move for a long time, and achieve the goal Manage and ensure the effectiveness of credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

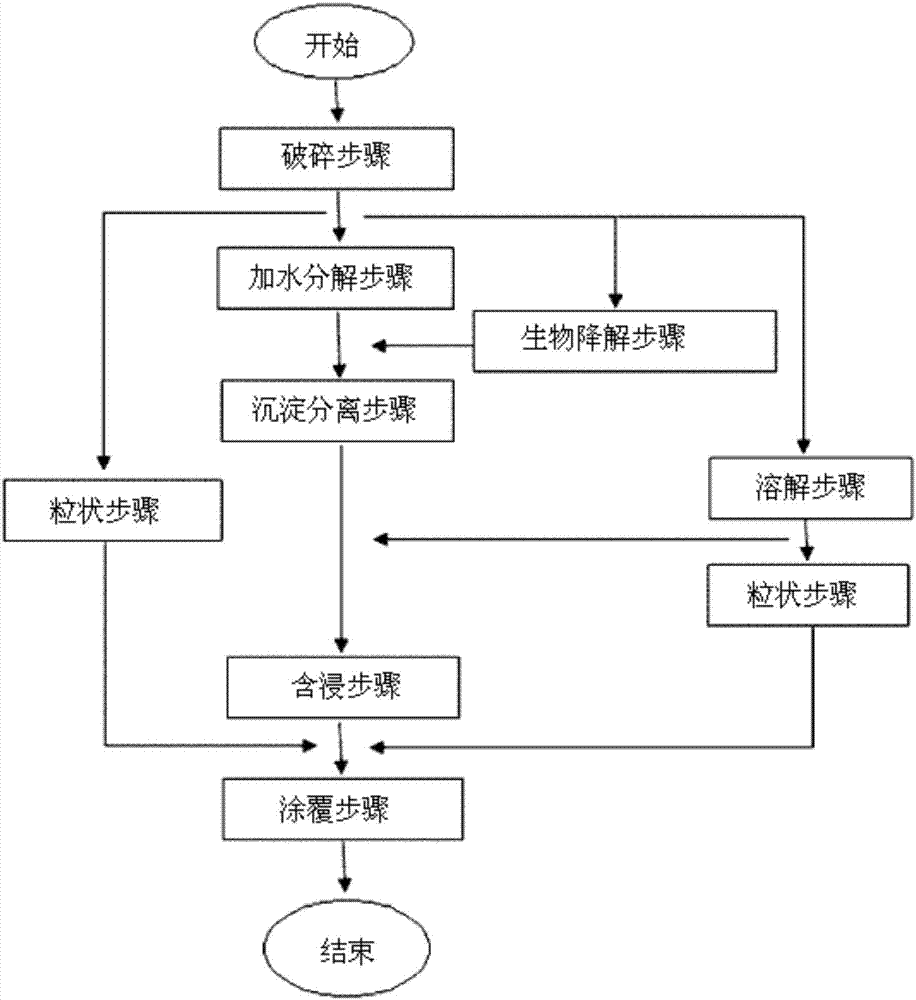

[0025] Hereinafter, the manufacturing method of the organic slow-release fertilizer according to the present invention will be described in detail with reference to the accompanying drawings.

[0026] The 12 elements of the essential nutrients according to the present invention are composed of N, P, K, Ca, Mg, S, Fe, Mn, Cu, B, Mo, Zn, and wherein nitrogen, phosphorus, potassium (potassium, also known as "Kalium") is a major element, calcium, magnesium, and sulfur are intermediate elements, and the rest are trace elements. In order to produce it, prepare oil residue (a general term for the sediment left after vegetable oil is extracted, including palm oil residue, soybean oil residue, rapeseed oil residue, cottonseed oil residue, castor oil residue, rice bran oil residue, Sesame oil residue, peanut oil residue, etc.), blood meal (blood of livestock, that is, animal blood, dried blood), by-products containing dead fish or fish bones and fish oil residue, bone meal, potassium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com