Preparation method of graphene oxide/nanosilver coating wrapped by collagen film

A technology of collagen film and collagen, which is applied in the field of preparation of graphene oxide/nano-silver coating wrapped in collagen film, can solve the problems of fast degradation speed and low mechanical properties of collagen, and achieve low investment in equipment and good quality. Photodynamic antibacterial activity, effect with little implementation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

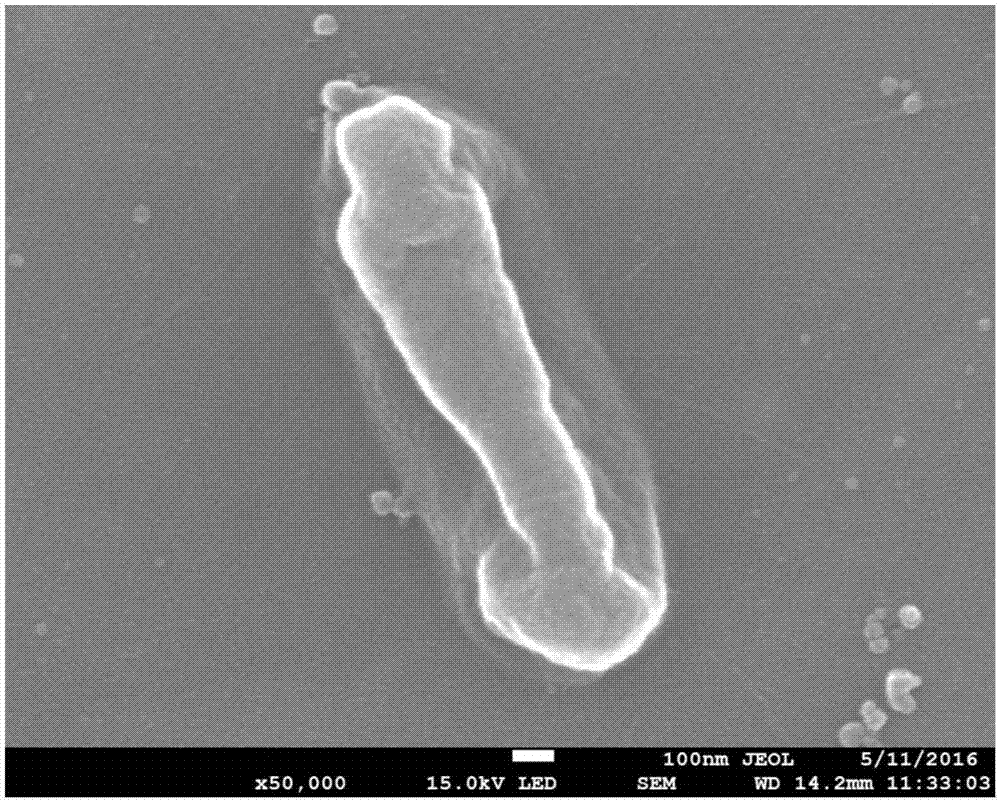

[0042] (1) Ultrasonic disperse the graphene oxide into a 1 mg / ml solution, take 50 ml and add 0.0679 g of silver nitrate, stir for 30 minutes, and place it under vacuum for 2 days in the dark. Finally, under the condition of continuous stirring, the solution was irradiated with 275 nm ultraviolet light for 1 hour, and the solution was set aside.

[0043] (2) Grind the medical titanium sheet to a smooth mirror surface on a polishing grinder with 240#, 400#, 600#, 800#, 1200# sandpaper, and then use 1:3 H 2 o 2 :H 2 SO4 The (concentrated) mixed solution was chemically etched for 30 minutes.

[0044] (3) Then put it into a reaction kettle filled with 4mol / L KOH solution, put the reaction kettle into an oven, react at 80°C for 90 minutes, and finally take it out for washing and drying.

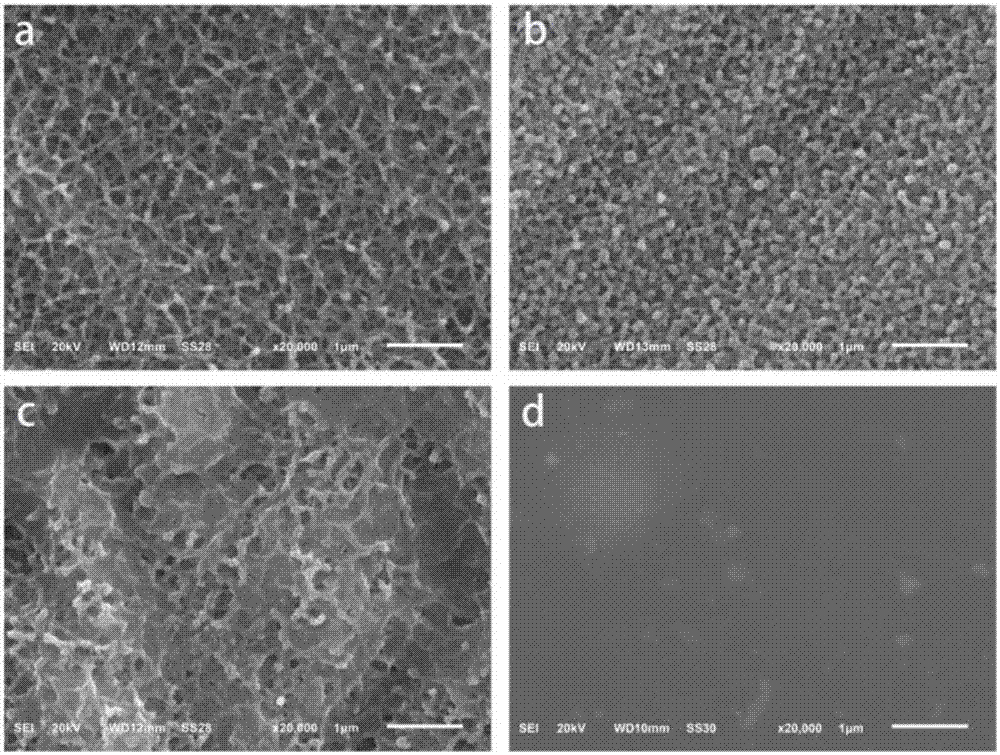

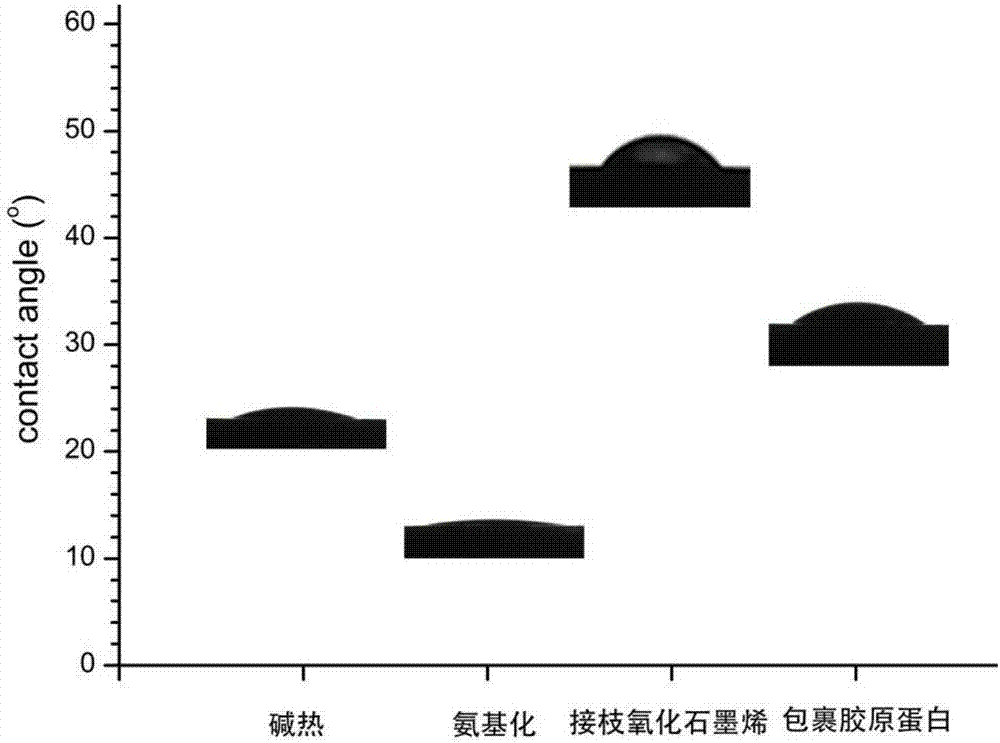

[0045] (4) Immerse the treated titanium sheet in 3% silane coupling agent toluene solution, reflux at 80° C. for 12 hours, take it out, wash and dry with ethanol. Then immerse in the graphene ...

Embodiment 2

[0049] (1) Prepare graphene oxide / silver nitrate solutions with concentrations of 1.2mg / L and 0.01mol / L respectively, place the prepared graphene oxide / silver nitrate solution in vacuum for 1 day, and then irradiate with ultraviolet light under continuous stirring Reduction to obtain a graphene oxide composite material uniformly loaded with nano-silver;

[0050] (2) After polishing the surface of a titanium metal disc with a diameter of 6 mm and a thickness of 2.5 mm with sandpaper, it was cleaned in acetone, distilled water, and alcohol in sequence, and then cleaned with 1:3 H 2 o 2 :H 2 SO 4 (concentrated) mixed solution chemical etching for 30 minutes

[0051] (3) Put the above-mentioned titanium sheet into a reaction kettle filled with a KOH solution with a concentration of 4mol / L, put the reaction kettle into an oven, react at 85°C for 80 minutes, take it out, wash and dry;

[0052] (4) Immerse the treated titanium sheet in 5% toluene solution of silane coupling agent...

Embodiment 3

[0055] (1) Prepare graphene oxide / silver nitrate solutions with concentrations of 1mg / L and 0.008mol / L respectively, place the prepared graphene oxide / silver nitrate solutions in vacuum for 2 days, and then irradiate and reduce them with ultraviolet light under continuous stirring A graphene oxide composite material uniformly loaded with nano-silver was obtained.

[0056] (2) Grind the titanium sheet with sandpaper of specifications 240#, 400#, 600#, 800#, and 1200# on a polishing grinder to a smooth mirror surface, and then use 1:4:5 HF:1mol / LHNO 3 :H 2 The mixed solution of O was chemically etched for 2 minutes, then put it into a reaction kettle filled with a KOH solution with a concentration of 4mol / L, put the reaction kettle in an oven, reacted at 80°C for 90 minutes, took it out, washed and dried;

[0057] (3) The titanium sheet after the above treatment was immersed in a Tris-HCl (pH=8.5) buffer solution containing 2 mg / mL dopamine hydrochloride in the dark, left for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com