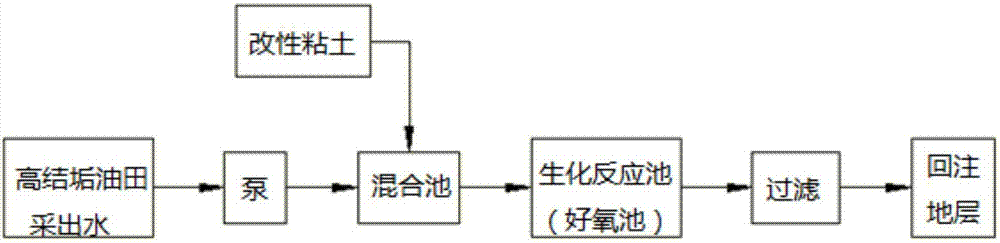

Method of treating highly scaling oil and gas field produced water with microorganisms assisted by modified clay

A technology for microbial treatment and produced water, which is used in biological water/sewage treatment, water/sewage treatment, mining wastewater treatment, etc. Efficient degradation of organic matter and other problems, to avoid the degradation of the degradation rate, optimize the descaling process link, and complete the adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]The oily sewage treatment process of Wuqi Oil Production Plant in Yanchang Oilfield is as follows: incoming water - natural degreasing - air flotation - biochemical pool - filtration - effluent, and the fouling amount of sewage at the entrance of the biochemical pool is 180-260mg / L, the oil content is 10-15mg / L, the suspended matter content is 5-10mg / L, when the operation is normal, the scaling amount at the outlet of the biochemical pool is 30-50mg / L, the oil content is ≤1mg / L, and the suspended matter content is 5 -10mg / L, the effluent after filtration meets the water quality requirements for reinjection water. However, within three months of operation, the scale deposited on the surface of the microbial particles in the biochemical tank caused the breakdown of the microbial treatment system, and the filter material of the filtration system was severely fouled, and the scale type was mainly calcium carbonate. According to the measurement, the fouling amount at the out...

Embodiment 2

[0041] The produced water of Xingzichuan Chang 2 formation in Yanchang Oilfield has a calcium ion content of Sulfate ion content The calcium ion content in the produced water of the Chang 6 formation is Sulfate ion content The produced water from the Chang 2 layer and the Chang 6 layer were mixed at a ratio of 9:1, and the scaling amount in 72 hours was 4478.25 mg / L. Pseudomonas was used to treat the mixed water sample, the amount of crude oil added was 4%, the amount of bacteria added was 2%, the stirring speed was 200r / min, the temperature was 37°C, the pH value was 7.5, and the degradation time was 7 days. The coalescence and deposition on the surface of the bacteria resulted in the blockage of the exchange of substances and energy between Pseudomonas and the outside world, and the degradation rate of crude oil changed from blank (simulated water: replace calcium ions with the same content of sodium ions in the long 2 and long 6 layers of water, and the rest ion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com