High current withstanding metallization film capacitor with long service life

A metallized film, long-life technology, used in film/thick film capacitors, capacitors, fixed capacitors, etc., can solve the problems of poor adhesion, capacitor breakdown accidents, small volume and other problems, to improve the withstand voltage and prolong the use. Longevity and effect of improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

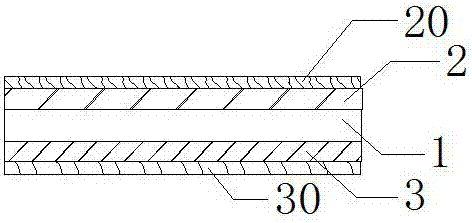

[0017] Such as figure 1 As shown, a metallized film capacitor with high current resistance and long life, comprising a base film 1 with a thickness of 350-450mm and a metal coating deposited on the base film, the metal coating is deposited on the upper and lower sides of the base film 1 , the metal coating on the base film 1 is an aluminum coating 2, and a shale oil layer 20 is coated on the outside of the aluminum coating 2, and the metal coating below the base film 1 is a zinc coating 3, and a silicon oil layer 30 is coated on the outside of the zinc coating 2;

[0018] Wherein, the coating condition of the aluminum coating is a vacuum pressure of 5.5×10 -4 mbar, the coating condition of the zinc coating is a vacuum pressure of 7.5×10 -4 mbar;

[0019] Wherein, the base film is made of the following raw materials in parts by weight: 28 parts of chlorosulfonated polyethylene, 18 parts of homopolypropylene, 12 parts of siloxane grafted modified acrylic resin, 5 parts of isob...

Embodiment 2

[0028] A metallized film capacitor with high current resistance and long life, comprising a base film with a thickness of 350-450 mm and a metal coating evaporated on the base film. The metal coating is an aluminum coating, and a shale oil layer is applied outside the aluminum coating, and the metal coating under the base film is a zinc coating, and a silicon oil layer is coated outside the zinc coating;

[0029] Wherein, the coating condition of the aluminum coating is a vacuum pressure of 5.5×10 -4 mbar, the coating condition of the zinc coating is a vacuum pressure of 7.5×10 -4 mbar;

[0030] Wherein, the base film is made of the following raw materials in parts by weight: 32 parts of chlorosulfonated polyethylene, 16 parts of homopolypropylene, 14 parts of siloxane grafted modified acrylic resin, 4 parts of isobutylene triethoxysilane , 3 parts of barium silicate, 10 parts of hydrocarbon propyl methylcellulose, 4 parts of polyoxyethylene polyoxypropanolamine ether, 0.5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com